Energy-saving type mine cable rapid suspension equipment

A mine cable and suspension equipment technology, applied in mining equipment, mining equipment, electrical components, etc., can solve problems such as suspension troubles, looseness, and cable sagging, and achieve the effects of convenient operation, sliding action, and safe distance distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

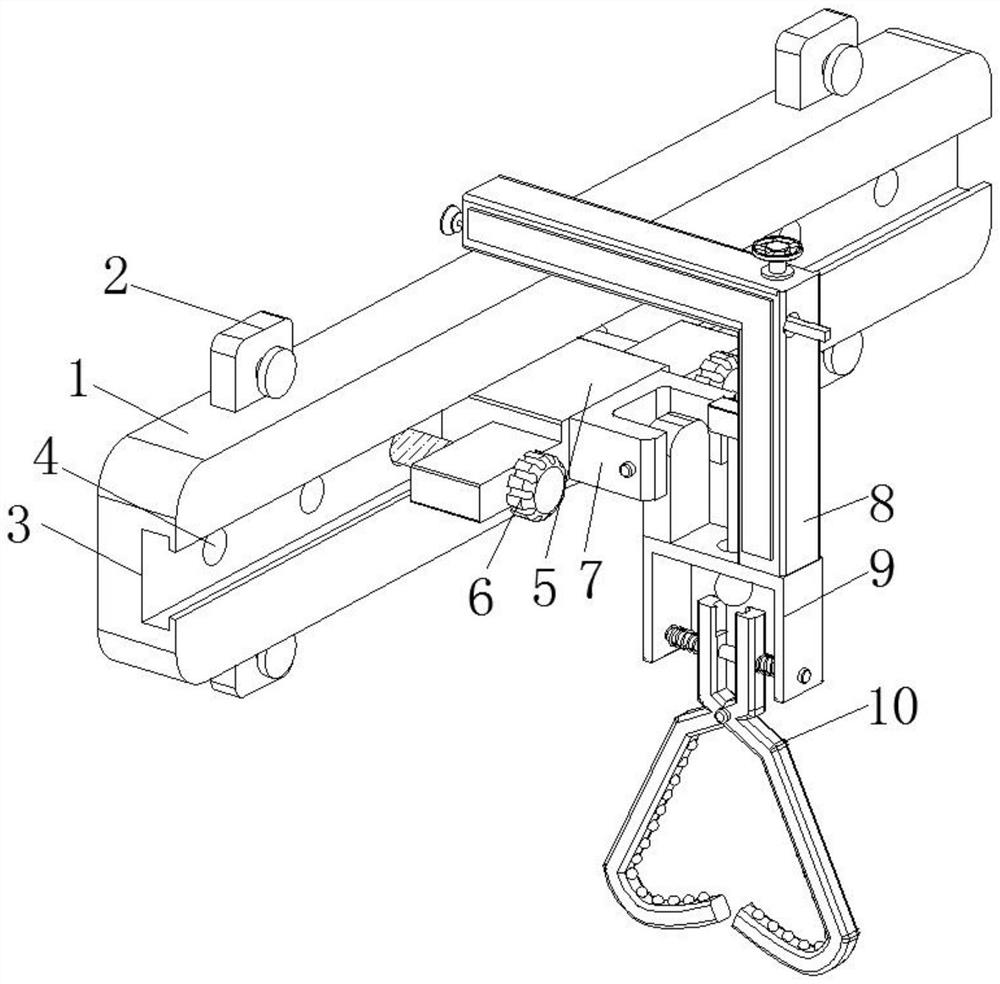

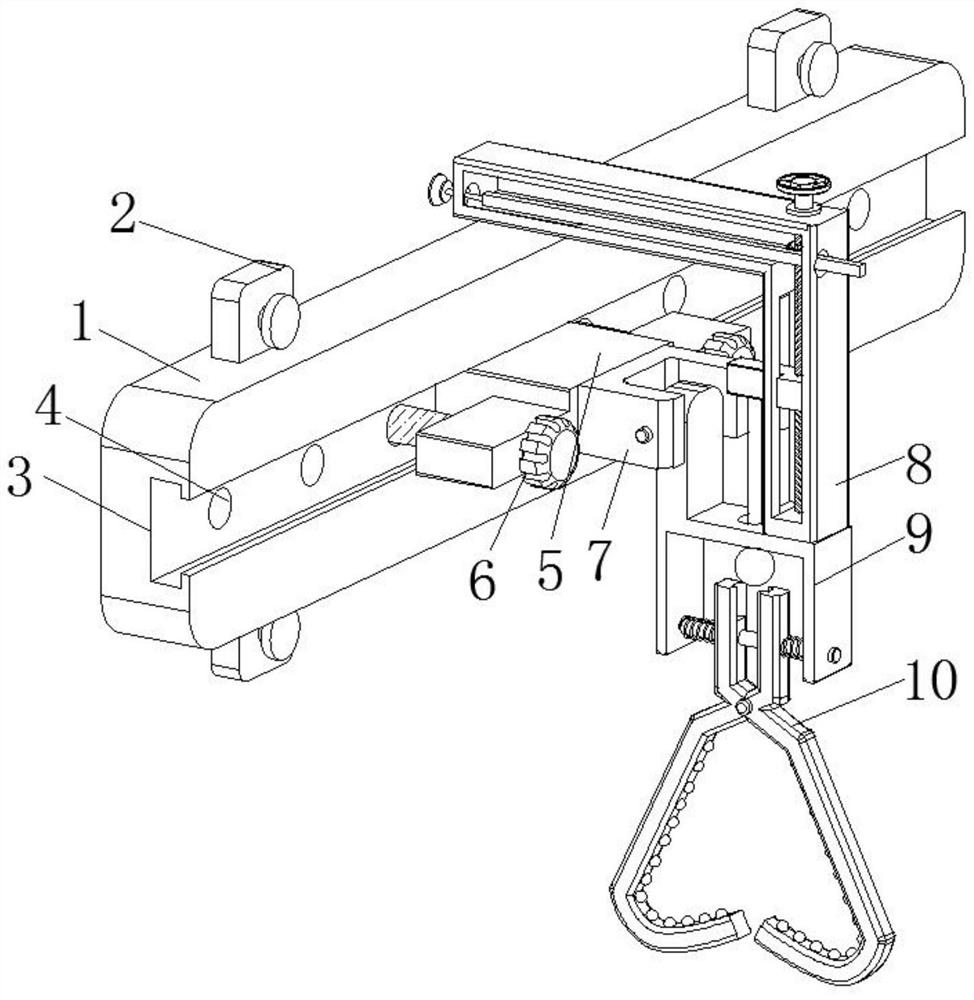

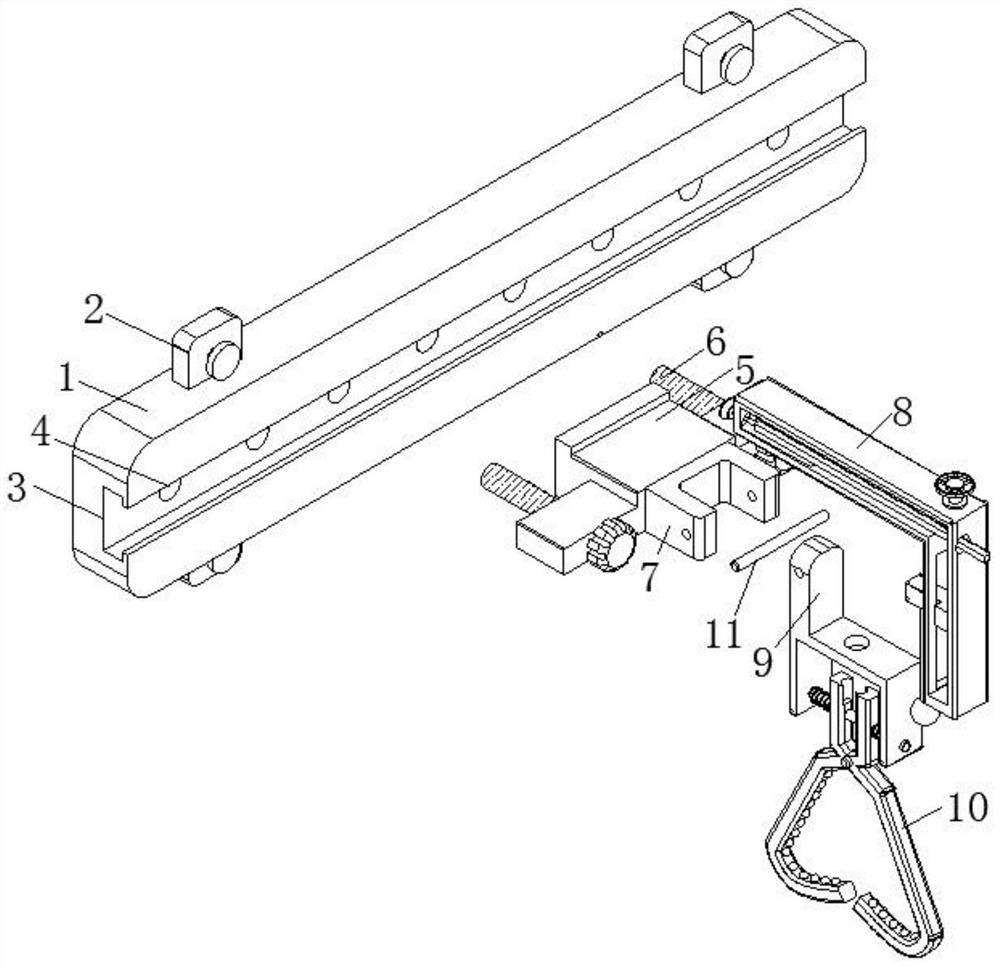

[0034] Such as Figure 1-6 As shown, the present invention provides a technical solution: an energy-saving quick suspension equipment for mine cables, including a mounting part, the mounting part is a rectangular mounting seat 1, and the right side wall of the rectangular mounting seat 1 is provided with a length equal to that of the rectangular mounting seat 1. Consistent T-shaped slot 3, T-shaped slider 5 slides inside the T-shaped slot 3, and the end of T-shaped slider 5 away from T-shaped slot 3 is fixed with a rotating seat 7, which is in the shape of "匚" and rotates A rotating shaft 11 is installed between the inner walls of the seat 7, and the outer circular surface of the rotating shaft 11 is movably connected with an adjusting assembly 9, so as to ensure that the adjusting assembly 9 can be perpendicular to the horizontal ground;

[0035] Specifically, the adjustment assembly 9 includes a fixed seat 901 that is movably connected to the outer surface of the rotating sh...

Embodiment 2

[0042] Such as Figure 7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the mounting part is also a U-shaped mounting seat 12, and the T-shaped groove 3 is also "U-shaped" and surrounded on the front surface of the U-shaped mounting seat 12.

[0043] Specifically, the use of the U-shaped mounting base 12 in conjunction with the T-shaped groove 3 can enable the advancing assembly 8, the adjusting assembly 9, and the clamping assembly 10 to move on a curved surface, and the use of multiple U-shaped mounting bases 12 can make The cable is bent and suspended on the wall of the tube well, which saves the space for cable suspension and further improves the practicability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com