Soft-packed cell electrode lug cutting die

A tab cutting and cell technology, which is applied in the field of molds for soft-pack cell tab cutting, can solve the problems of poor dimensional consistency, reduced qualification rate, improper operation, etc., and achieves high dimensional consistency, Improve the efficiency of processing and the effect of good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

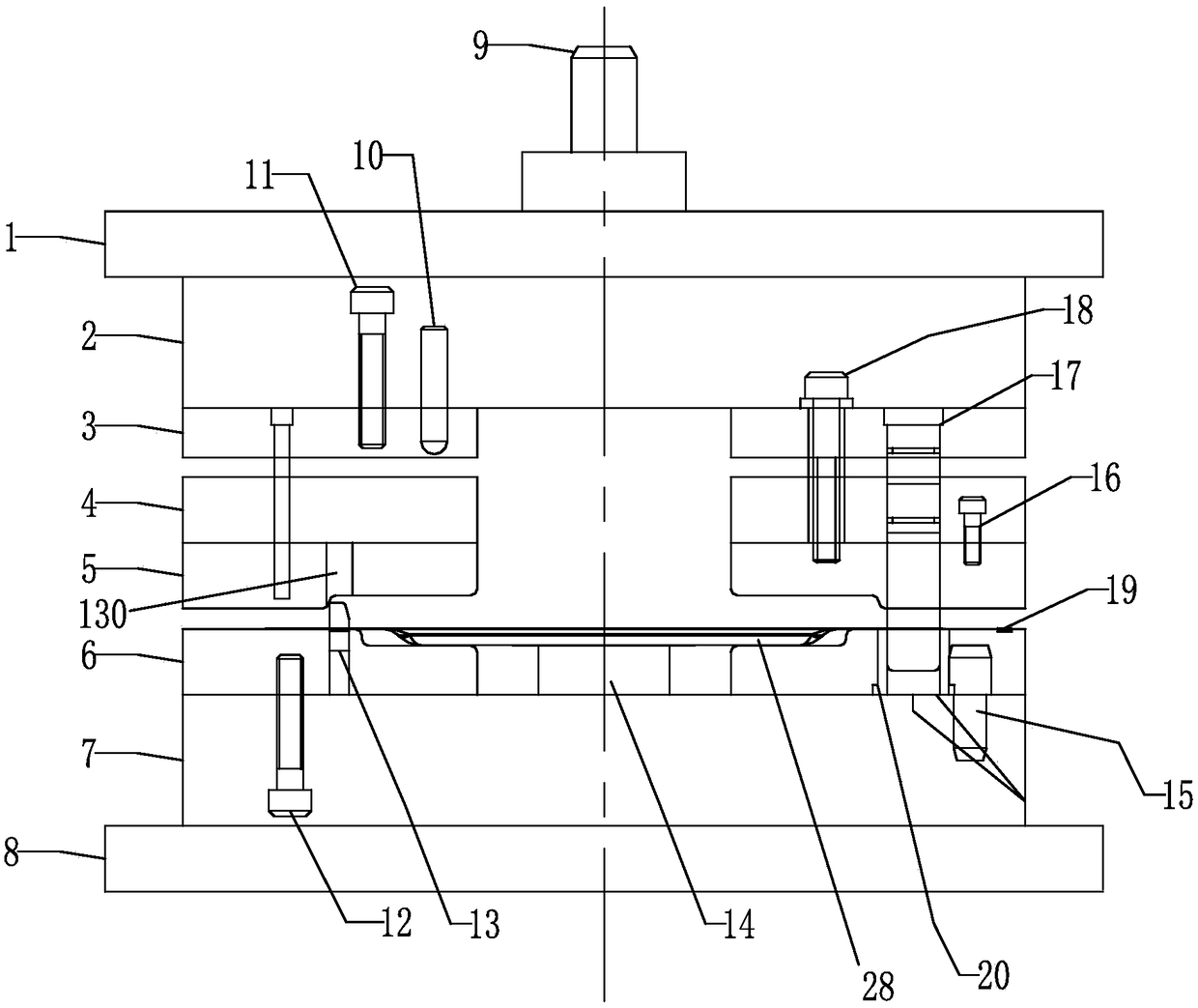

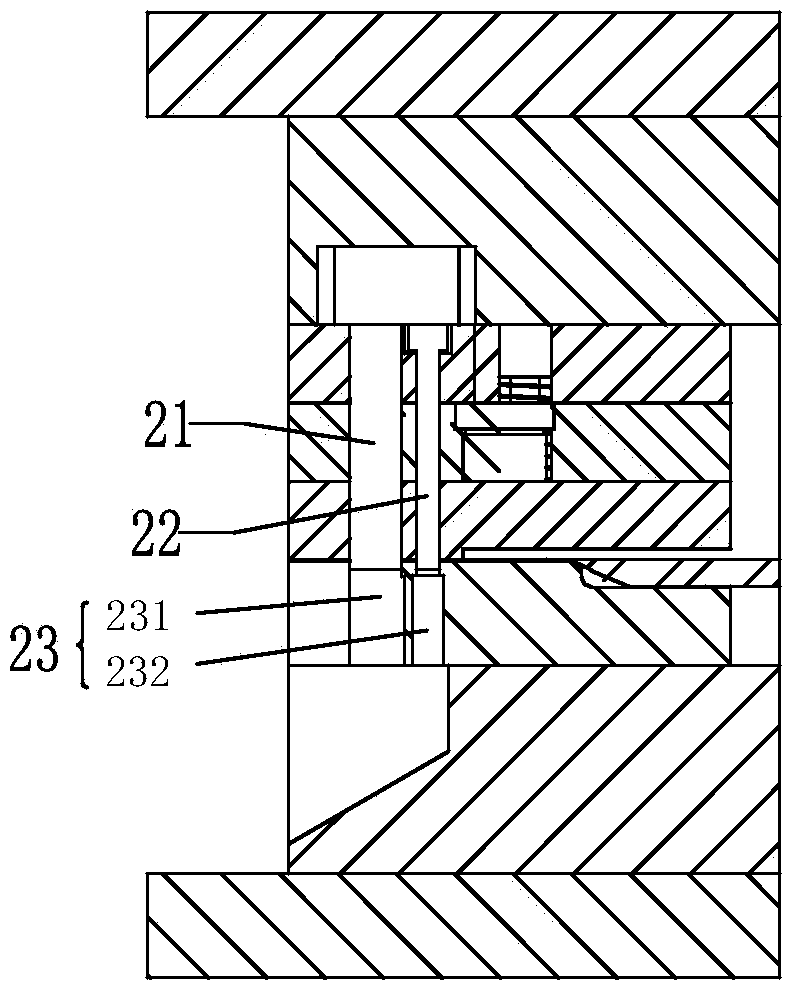

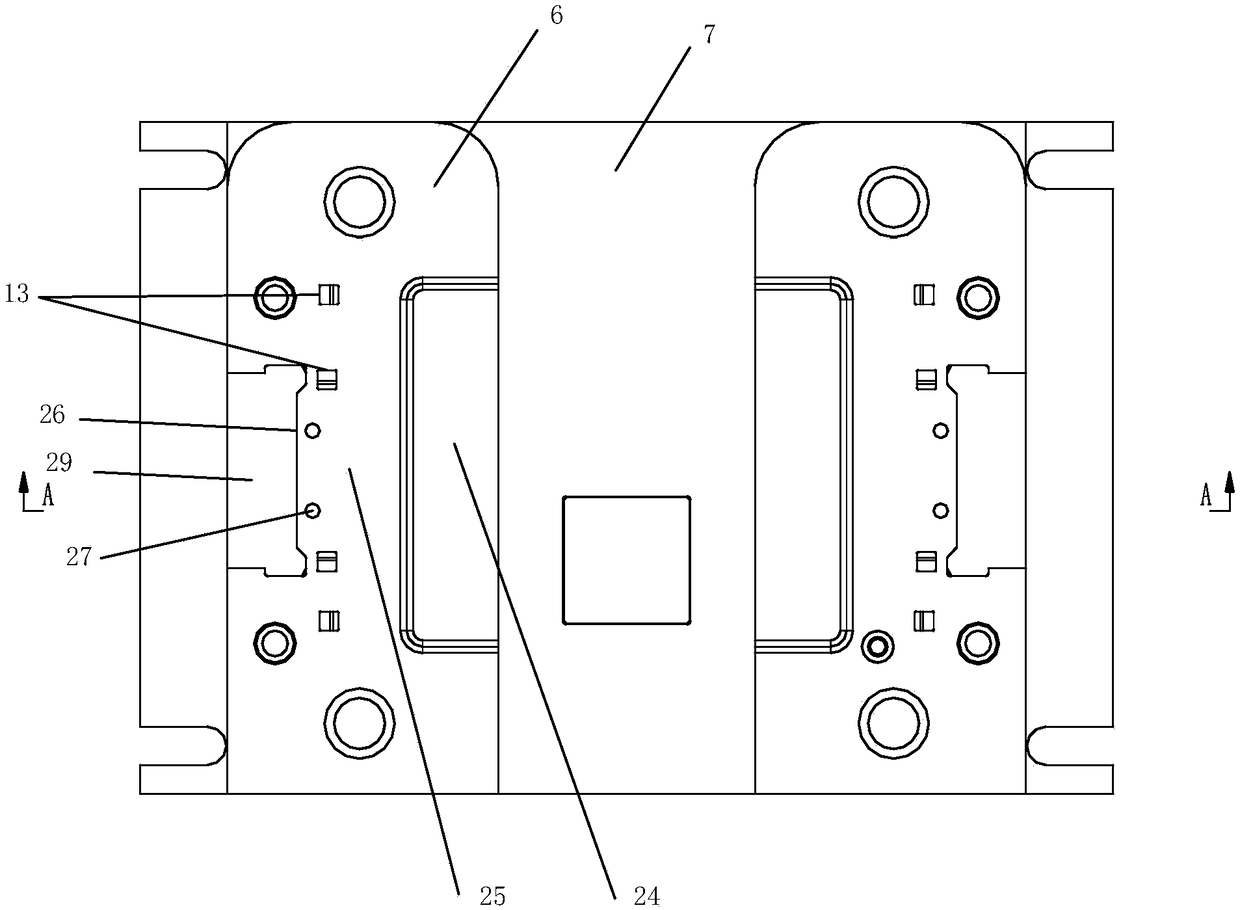

[0025] Such as figure 1 As shown, the soft package lithium ion capacitor lug shearing mold of the present invention includes an upper mold and a lower mold, and the upper mold includes an upper mold base 1, and an upper mold made of a non-metallic material is arranged below the upper mold base 1. The fixed plate 2 and the lower part of the upper fixed plate 2 are fixed with two main punching and shearing mechanisms, and the two main punching and shearing mechanisms are symmetrical about the central axis of the mold. The main punching and shearing mechanism includes an upper clamping plate 3, a stopper plate 4 and a material shifting plate 5 fixedly connected sequentially from top to bottom, wherein the stopper plate 4 is made of non-metallic material, and the upper clamping plate 3 is fastened by the upper clamping plate The screw 11 is fixed below the upper clamping plate 2. For preventing the rocking of the upper clamping plate fastening screw 11, the upper clamping plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com