Rotary impact cushioning safety helmet

一种冲击缓冲、安全帽的技术,应用在帽类制品、服饰、扣件等方向,能够解决承受外力旋转冲击能力差、头部易受挫伤等问题,达到提高保护作用、减少冲击的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

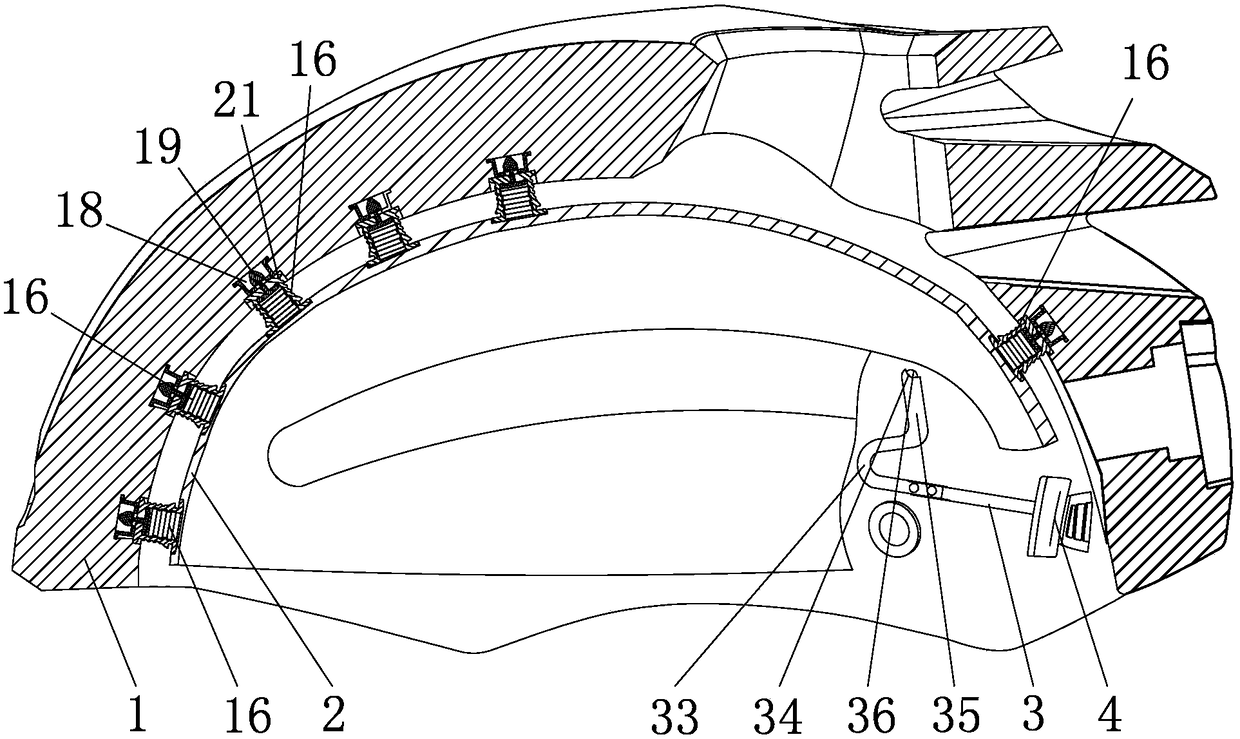

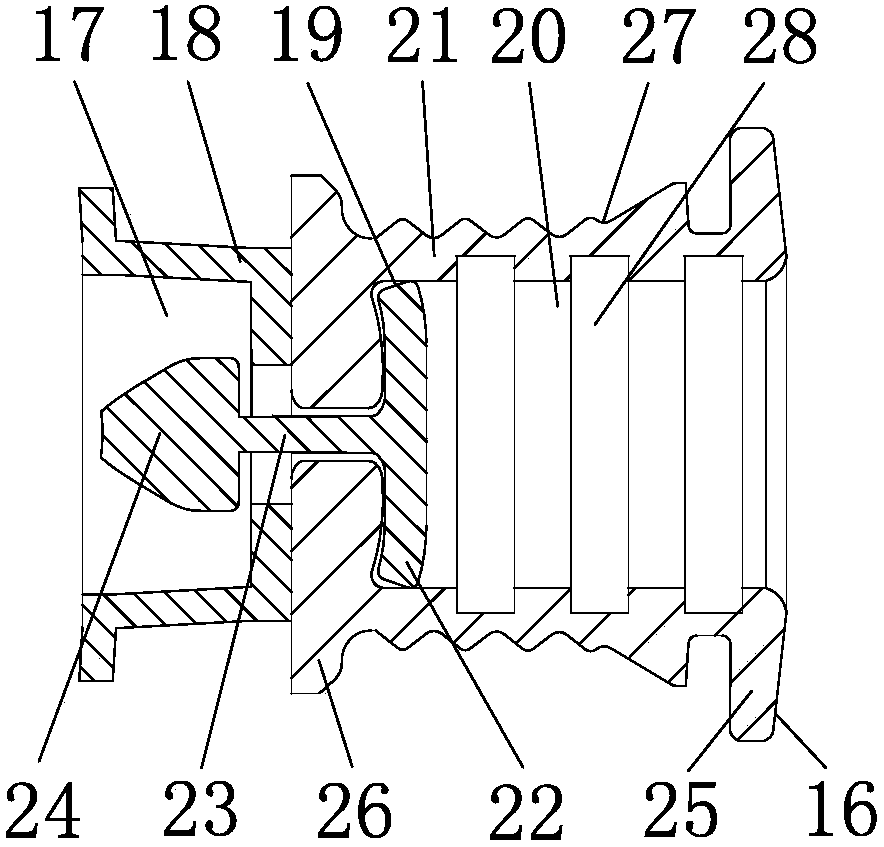

[0025] in such as figure 1 , figure 2 In the shown embodiment 1, a rotating impact buffering safety helmet includes a shell 1, and the rotating impact buffering safety helmet also includes an elastic inner lining 2 arranged in the outer shell, and the material of the elastic inner lining is PC board or foam Cotton; there is a gap between the outer shell and the elastic inner lining, and a rotating impact buffer device that makes the outer shell rotate relative to the elastic inner lining is provided between the outer shell and the elastic inner lining; the described rotating impact buffer device includes 21 buffer members 16, and the The buffer member includes a plastic nail seat 18 embedded in the shell and a columnar elastic washer 21. The plastic nail seat is provided with an outer stepped hole 17 with a small diameter end located at the inner end; the elastic washer is provided with an inner stepped hole 20 with a small diameter end located at the outer end. , the outer ...

Embodiment 2

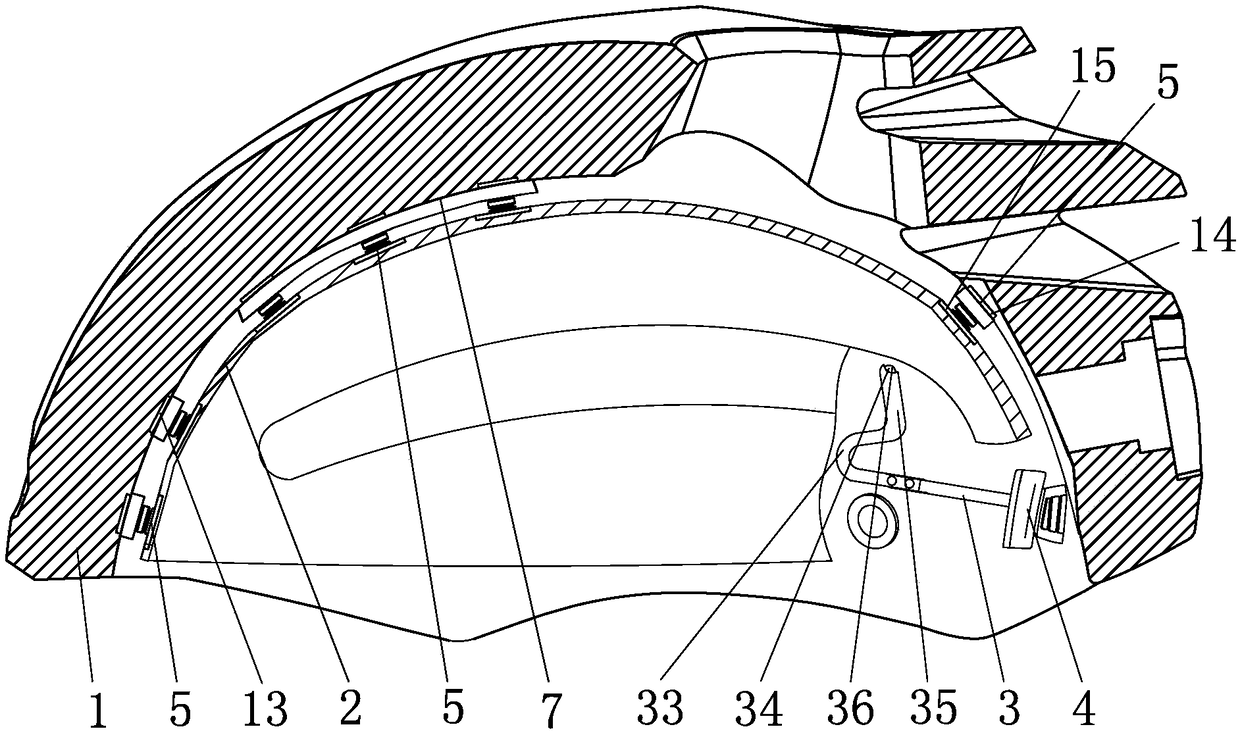

[0028] in such as image 3 , Figure 4 In the shown embodiment 2, the rotary impact buffer device includes seven buffer assemblies 5, and the buffer assembly includes: a mounting plate 8 provided with three columnar buffer washers 6 and bonded to the inner side of the casing by double-sided adhesive tape 7, so that The mounting plate described above is provided with mounting holes 10 having the same number as the number of buffer washers, and the buffer washers are inserted in the mounting holes in one-to-one correspondence; In the buffer column 9, the material of the buffer washer and the buffer column is silica gel, the length of the buffer column is less than the depth of the inner hole of the buffer washer, the height of the buffer washer is greater than the thickness of the mounting plate, and the inner end of the buffer washer is bonded to the elastic lining . The outer side of the buffer washer is provided with three outer grooves 11, and the inner hole side of the bu...

Embodiment 3

[0030] in such as Figure 5 In the shown embodiment 3, the rotary shock buffer device includes: a depression 29 arranged inside the shell, 24 elastic support columns 30 whose outer ends are connected to the bottom surface of the depression, and positioning holes with the same number as the number of elastic support columns are provided. The buffer pad 32 of 31, the buffer pad is placed in the depression and the positioning holes are correspondingly sleeved on the outer ends of the elastic support columns, and the inner ends of the elastic support columns are bonded to the elastic inner lining. In this embodiment, the material of the elastic support column is nylon, the cross-sectional shape is a regular hexagon, the material of the buffer pad 32 is silica gel, and the rest are the same as in the first embodiment.

[0031] After testing, compared with the traditional helmets, the rotary impact buffering helmets of the three embodiments of the present invention are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com