An automatic hydraulic angle cutting machine for photo frame production and its realization method

An implementation method and technology of cutting angle machine, which are applied in special forming/shaping machines, forming/shaping machines, manufacturing tools, etc., can solve the problems of poor use effect, not easy to cut corners, uneven cutting surfaces, etc., and achieve structural Simple, easy to process, neat and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

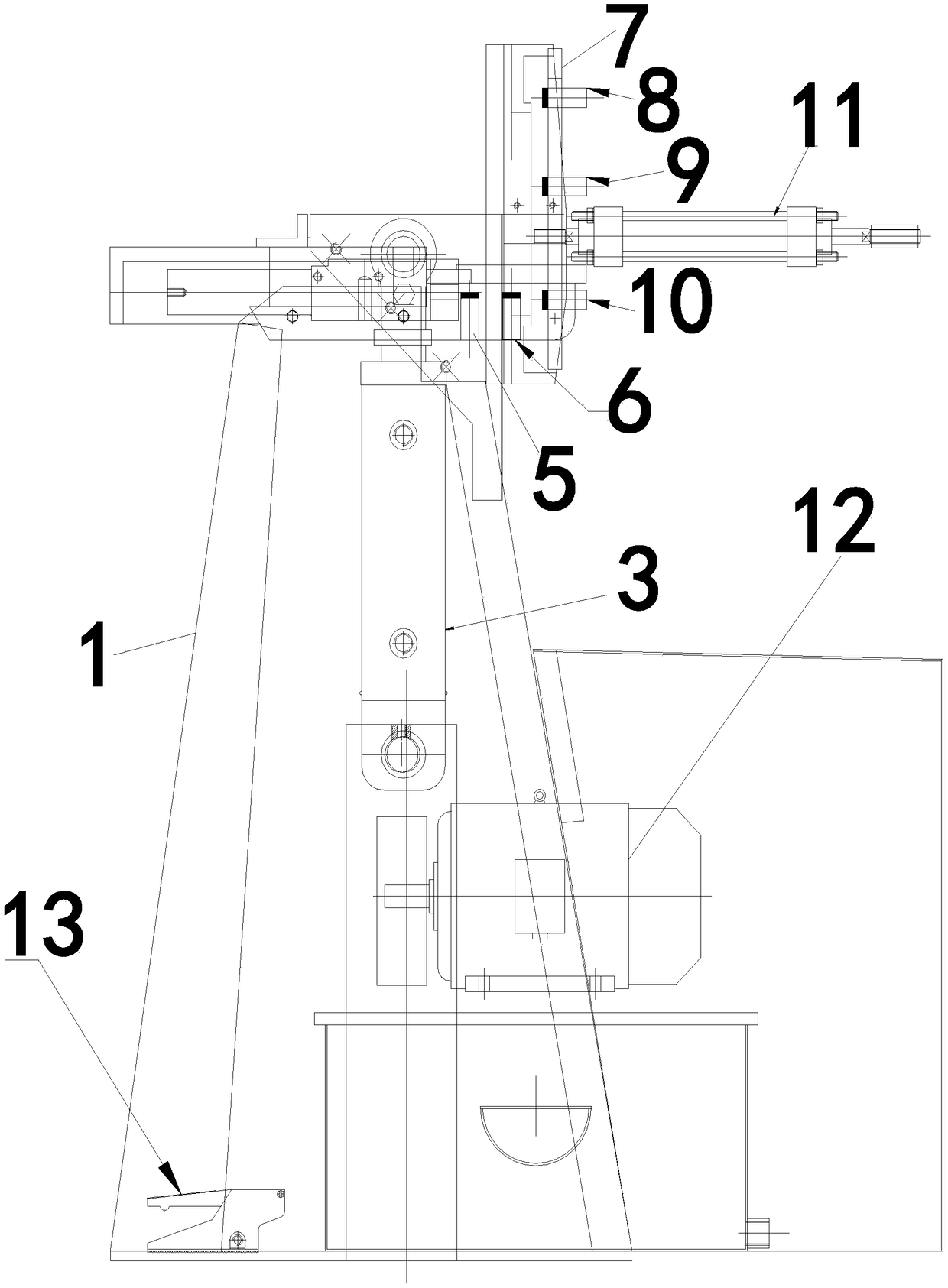

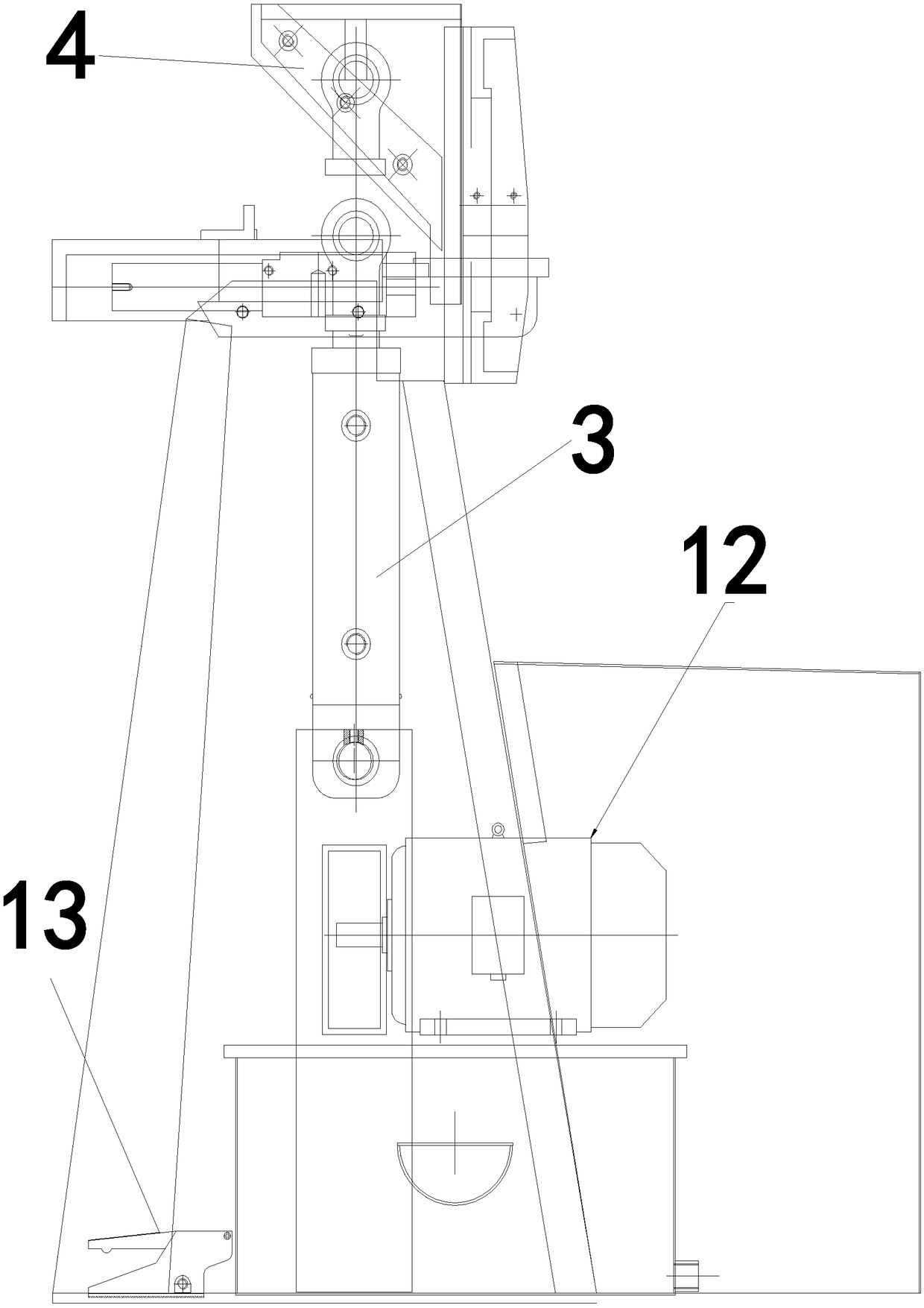

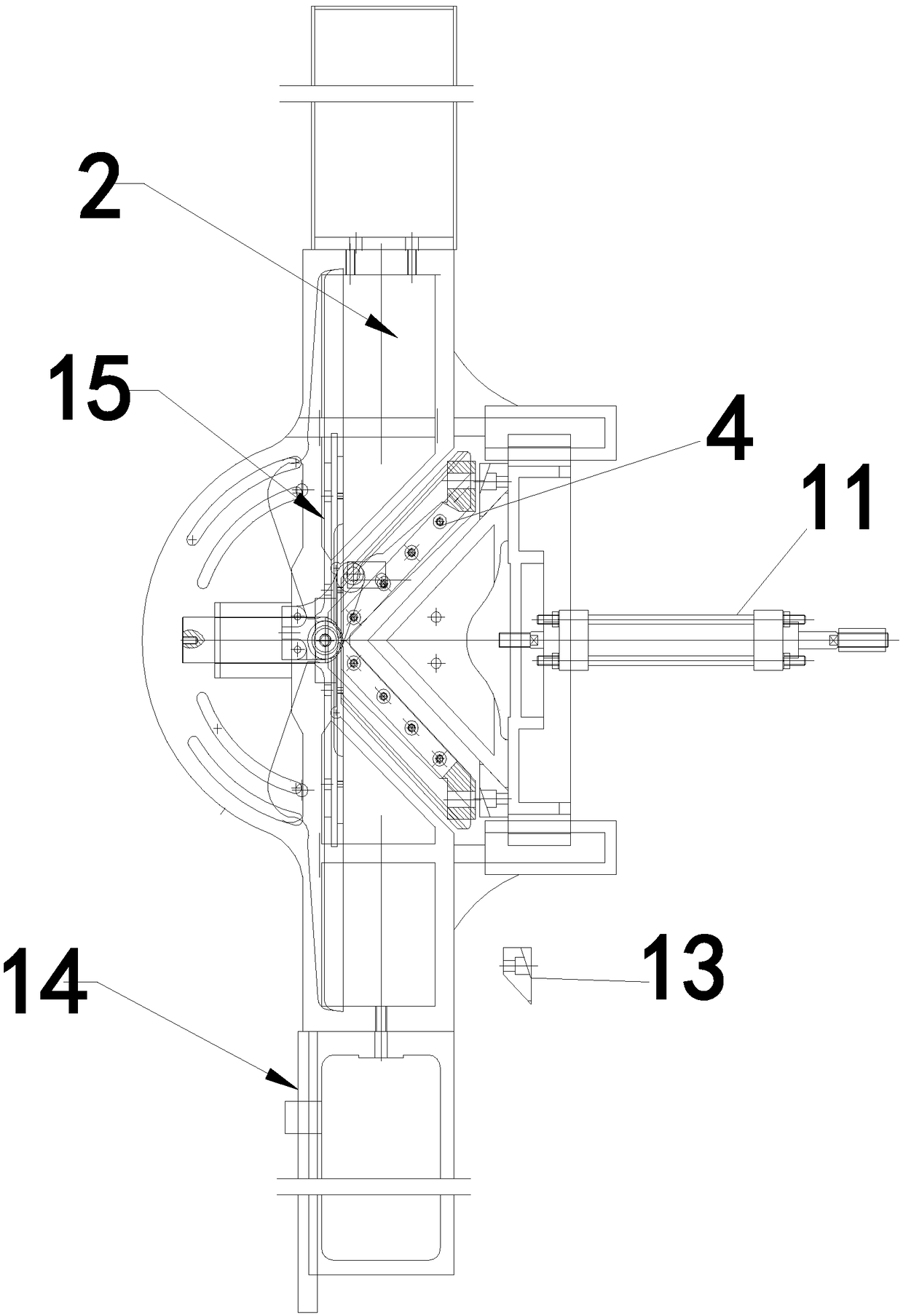

[0033] Such as Figure 1~3 As shown, an automatic hydraulic angle cutting machine for photo frame production, including a frame, a working platform is arranged on the frame, a longitudinal hydraulic cylinder is arranged under the working platform, and the longitudinal hydraulic cylinder is connected with a bevel cutter, and the horizontal position of the working platform is There is a left sensor switch and a right sensor switch, and a mounting plate is set on the side of the rack. The top limit sensor switch, the middle touch sensor switch and the bottom limit sensor switch are arranged on the mounting plate sequentially from top to bottom, and the middle touch sensor switch is below There is a horizontal hydraulic cylinder, which is connected to the oblique cutter, and the motor hydraulic pump is respectively connected to the longitudinal hydraulic cylinder and the horizontal hydraulic cylinder. Hydraulic pump, left sensor switch, right sensor switch, top limit sensor switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com