State monitoring control system for large-scale vibrating screen

A technology of monitoring control and vibrating screen, which is applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables. It can solve the problems of dependence on labor, poor control accuracy, and complicated operation, and achieve convenient operation and high cost performance. , the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

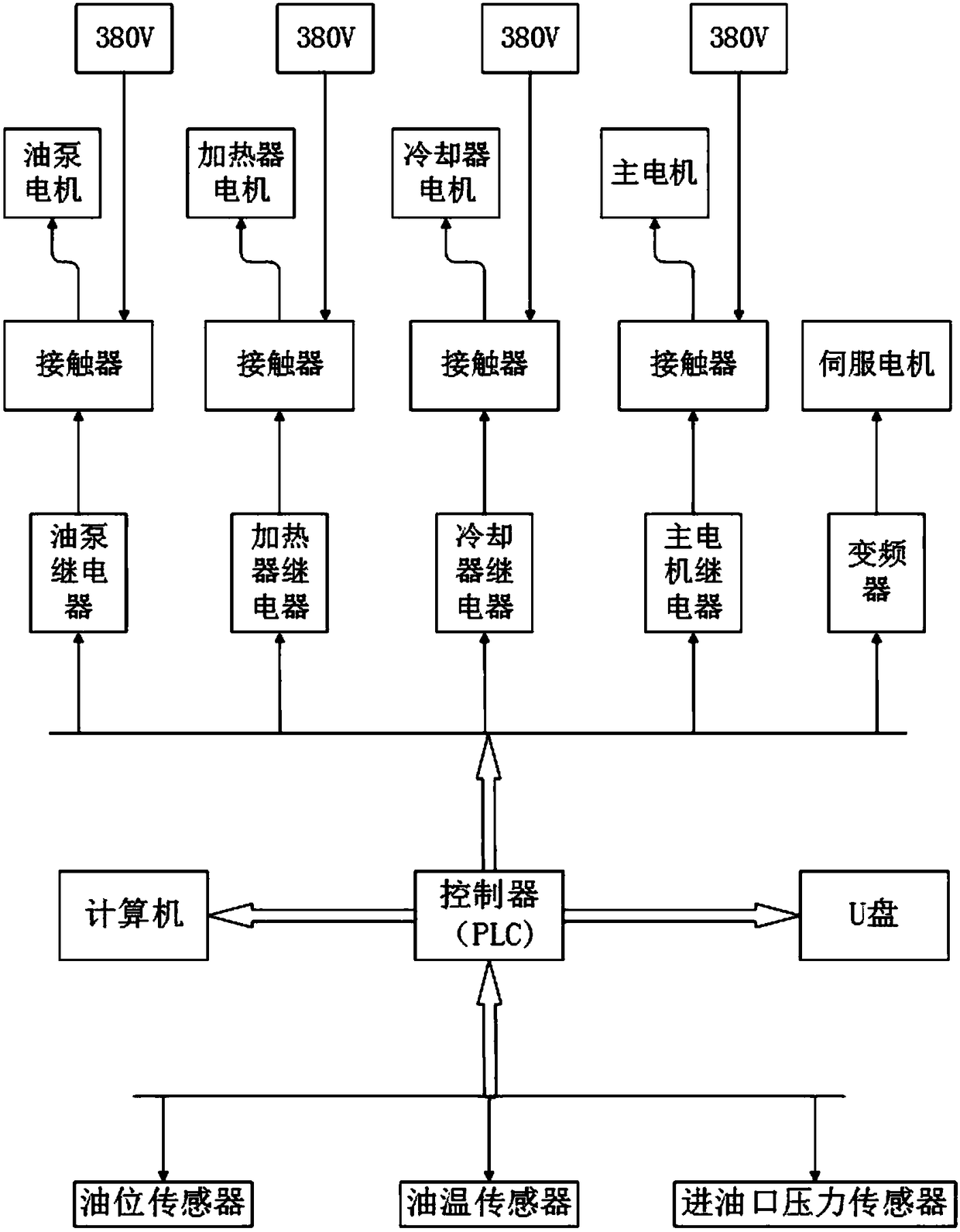

[0036] In order to ensure the formation of a stable and reliable lubricating oil film for the large vibrating screen bearings, the present invention designs a PLC-based state monitoring and control system for large vibrating screens. The system works as follows:

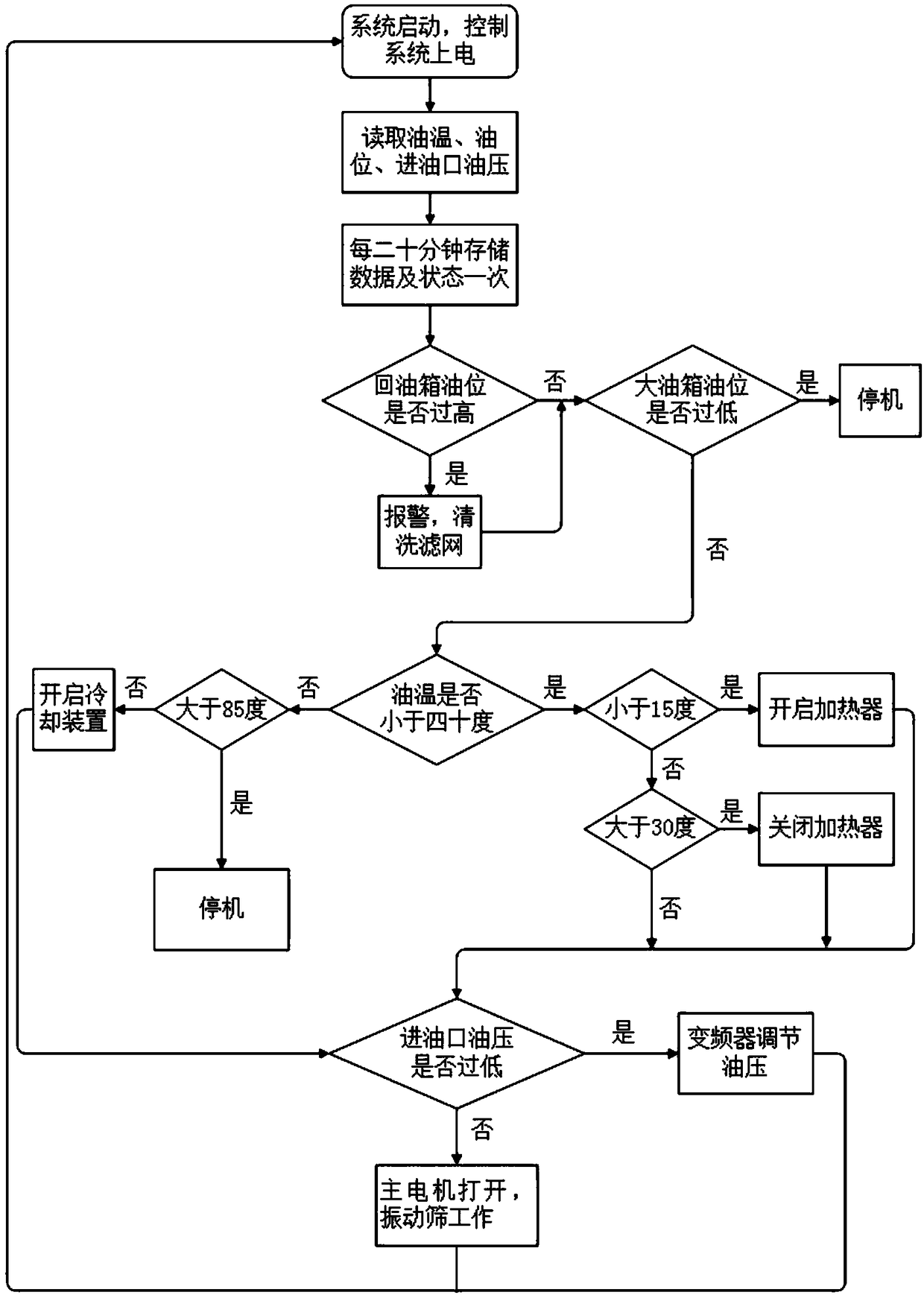

[0037] (1) Real-time status monitoring and data recording operations.

[0038] Such as figure 1 As shown, the 4-20Ma signal of the sensor transmitter including temperature and pressure enters the PLC controller, and the data is converted into status information. The data can be displayed in real time by communicating the PLC controller with the host computer through industrial Ethernet. The PLC controller communicates with the serial port USB through the RS485 / RS232 cable, and can store the state information of the vibrating screen bearing in EXCEL form, and the timer in the PLC can store the current data every 20 minutes.

[0039] (2) Automatic control of oil temperature and pressure operation.

[0040] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com