Device and method for controlling macroporous resin liquid level by automatic instrument

A technology of macroporous resin and instrumentation, which is applied in the field of traditional Chinese medicine pharmaceutical control, can solve the problems of not being able to achieve the adsorption effect and accurately control the liquid level of macroporous resin, so as to ensure automation and continuity, powerful logic computing ability, and accurate Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

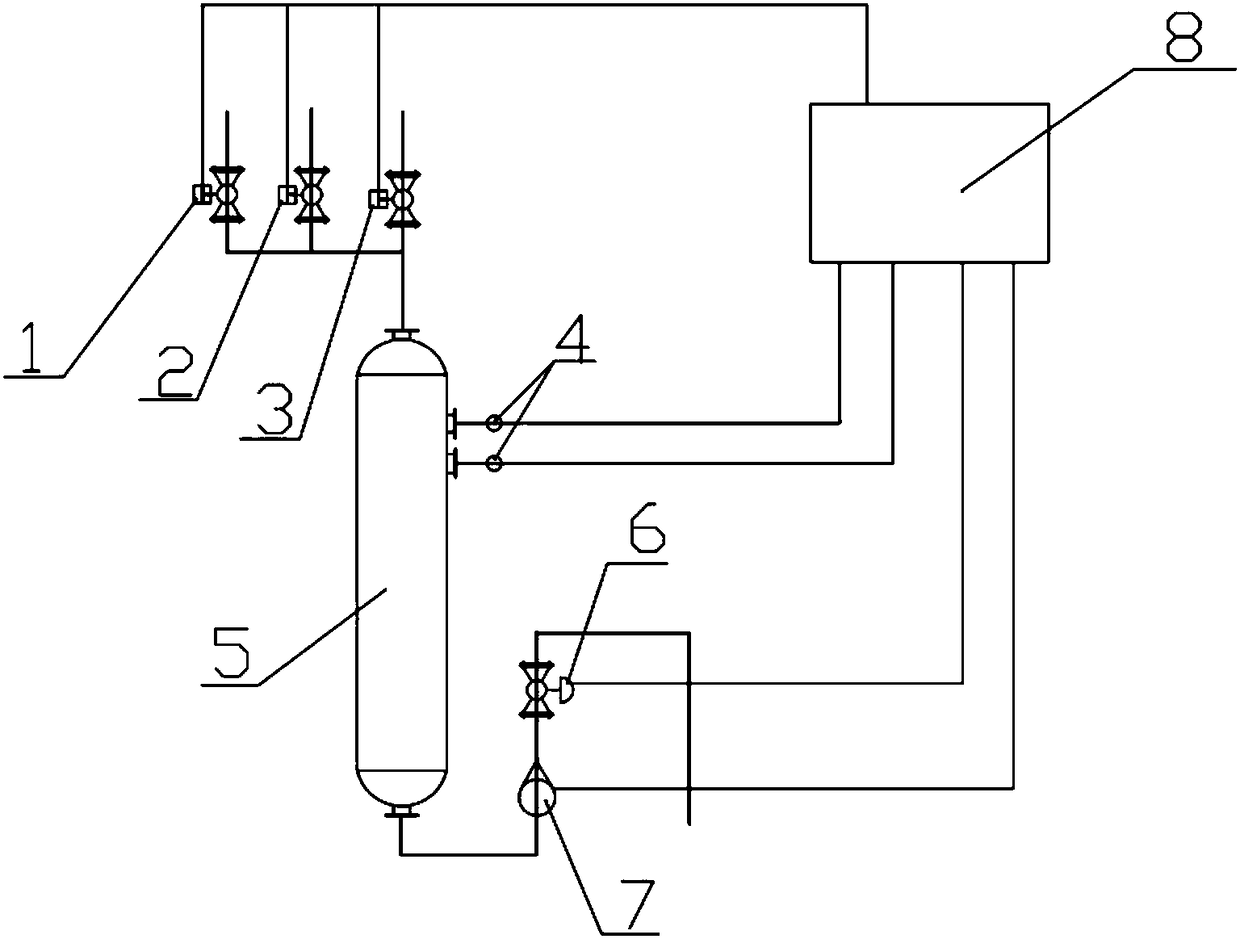

[0022] see figure 1 , The present invention relates to a device for controlling the liquid level of macroporous resin by an automatic instrument, comprising a resin column 5, a liquid medicine inlet valve 1, a cleaning liquid inlet valve 2, an eluent inlet valve 3, a liquid level switch 4, a regulating valve 6, Liquid flow meter 7 and controller 8. Among them, the resin column 5 is a DN400 resin column; the medicine solution inlet valve 1, the cleaning solution inlet valve 2 and the eluent inlet valve 3 are pneumatic valves, and the medicine solution, cleaning solution and eluent entering the resin column pass through their respective pipelines in sequence and valves, must not be mixed, in the present embodiment, the cleaning liquid is selected from drinking water, and the eluent is selected from ethanol; the liquid level switch 4 is a float type liquid level switch; the regulating valve 6 is a pneumatic regulating valve; the liquid flow meter 7 is a rotameter ; The controlle...

Embodiment 2

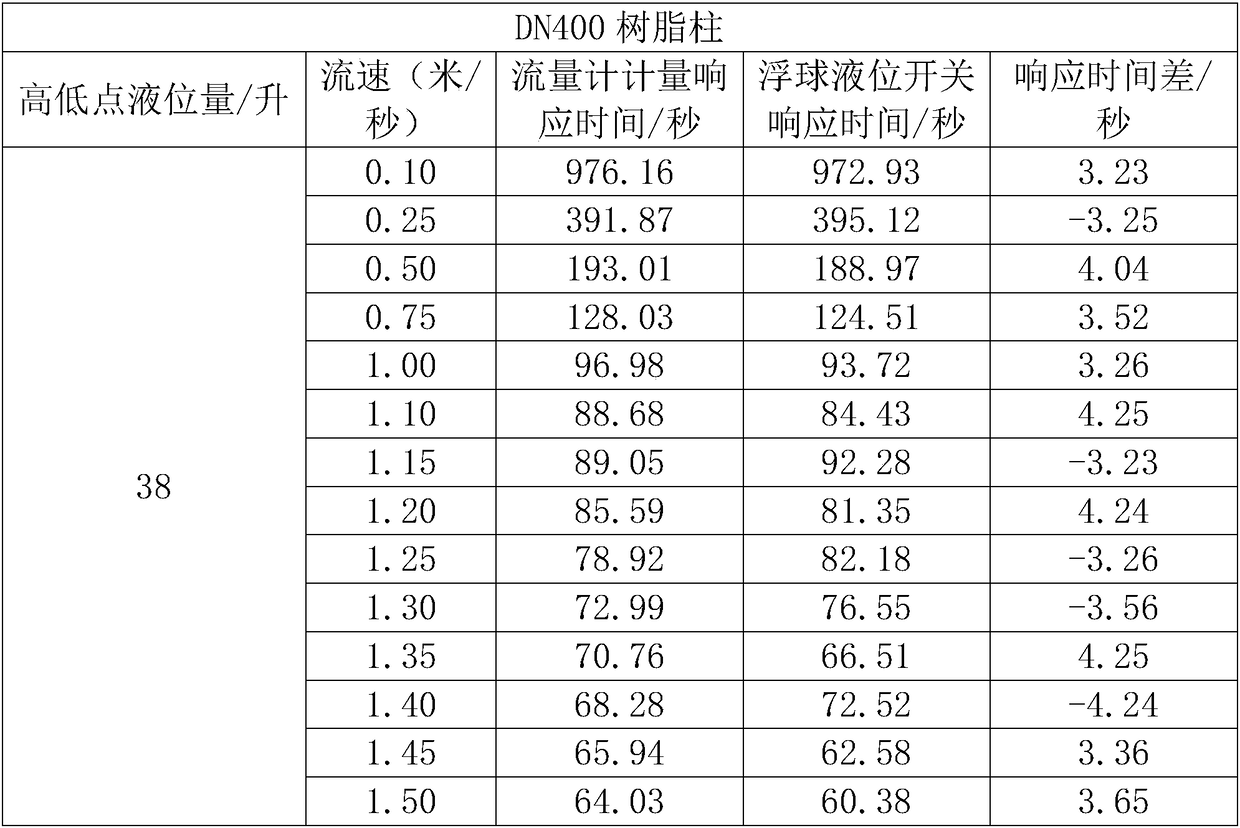

[0025] In the process of automatically controlling the liquid level of the macroporous resin, the controller 8 timed the two outlet times of the liquid inlet in the resin column 5 from the high level to the low level, that is, the signal measurement reaction time of the liquid outlet flowmeter 7 and the liquid level switch 4’s signal triggers the reaction time, comparing the two time data, it is found that under certain liquid density and temperature conditions, the data coincidence is good, which shows that the performance of the liquid level switch 4 is relatively stable and accurate and reliable, further, because There are uncertainties in the response time of the liquid level switch 4 and the response value under different flow rate ranges. In order to further confirm the reliability and accuracy of the liquid level switch, the response time of the liquid level switch 4 is detected at different flow rates, in which the resin There is a difference of 38L between the high and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com