Muffler for air inlet of axial flow fan

A technology of axial flow fan and air inlet, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of large air inlet muffler, large noise of axial flow fan, general noise reduction effect, etc., and achieve noise reduction Remarkable effect, reduce wind resistance, reduce noise radiation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

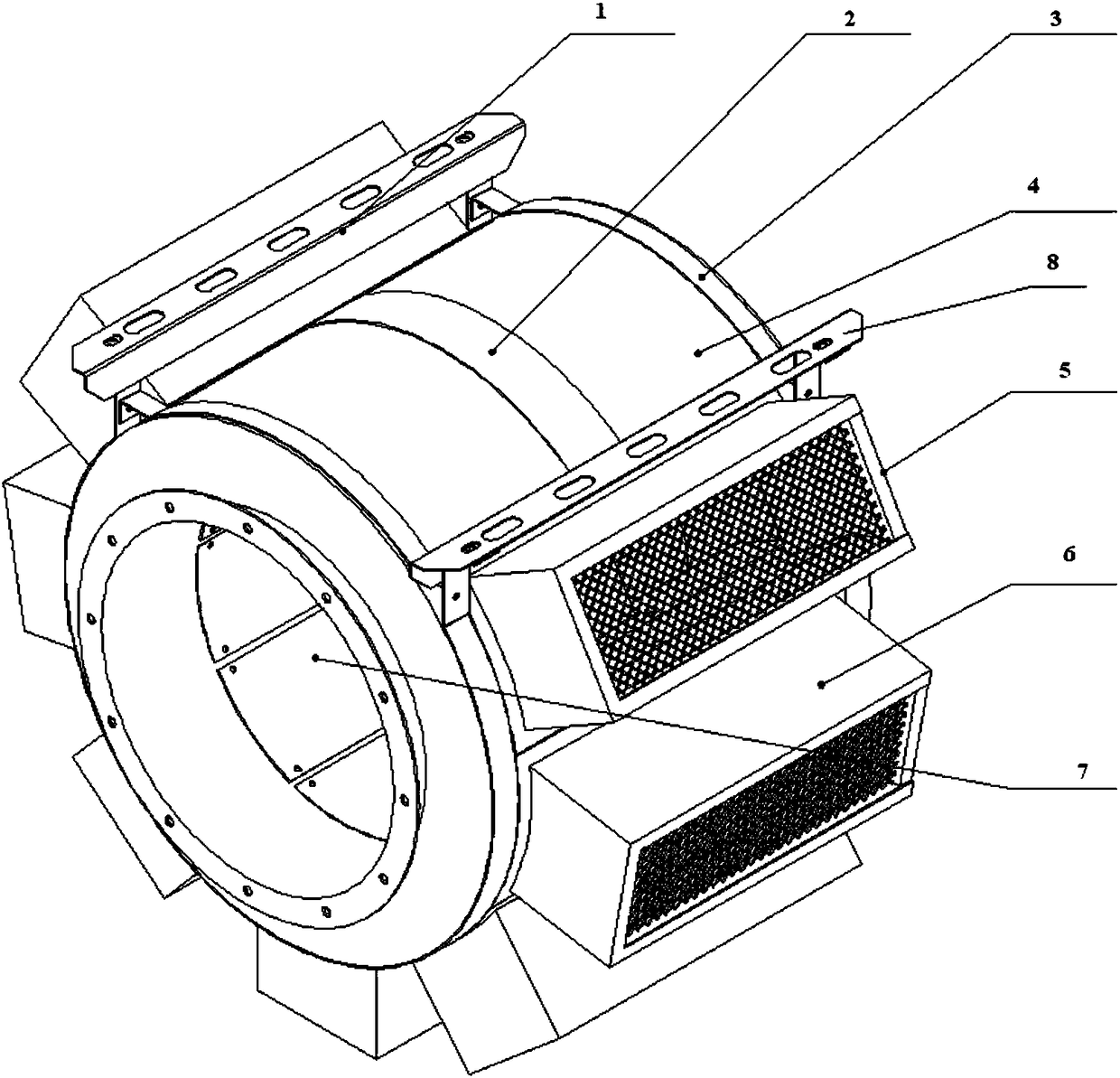

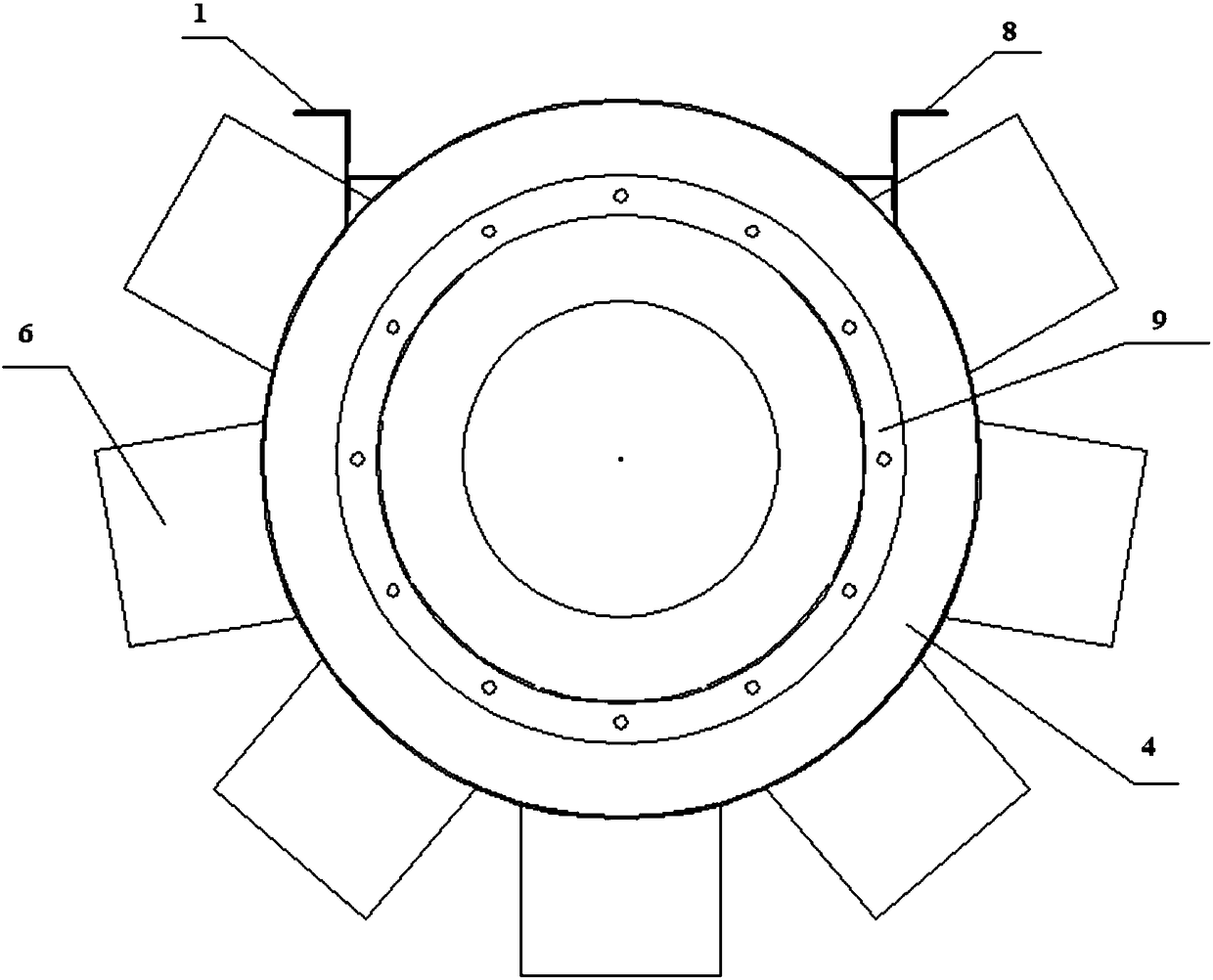

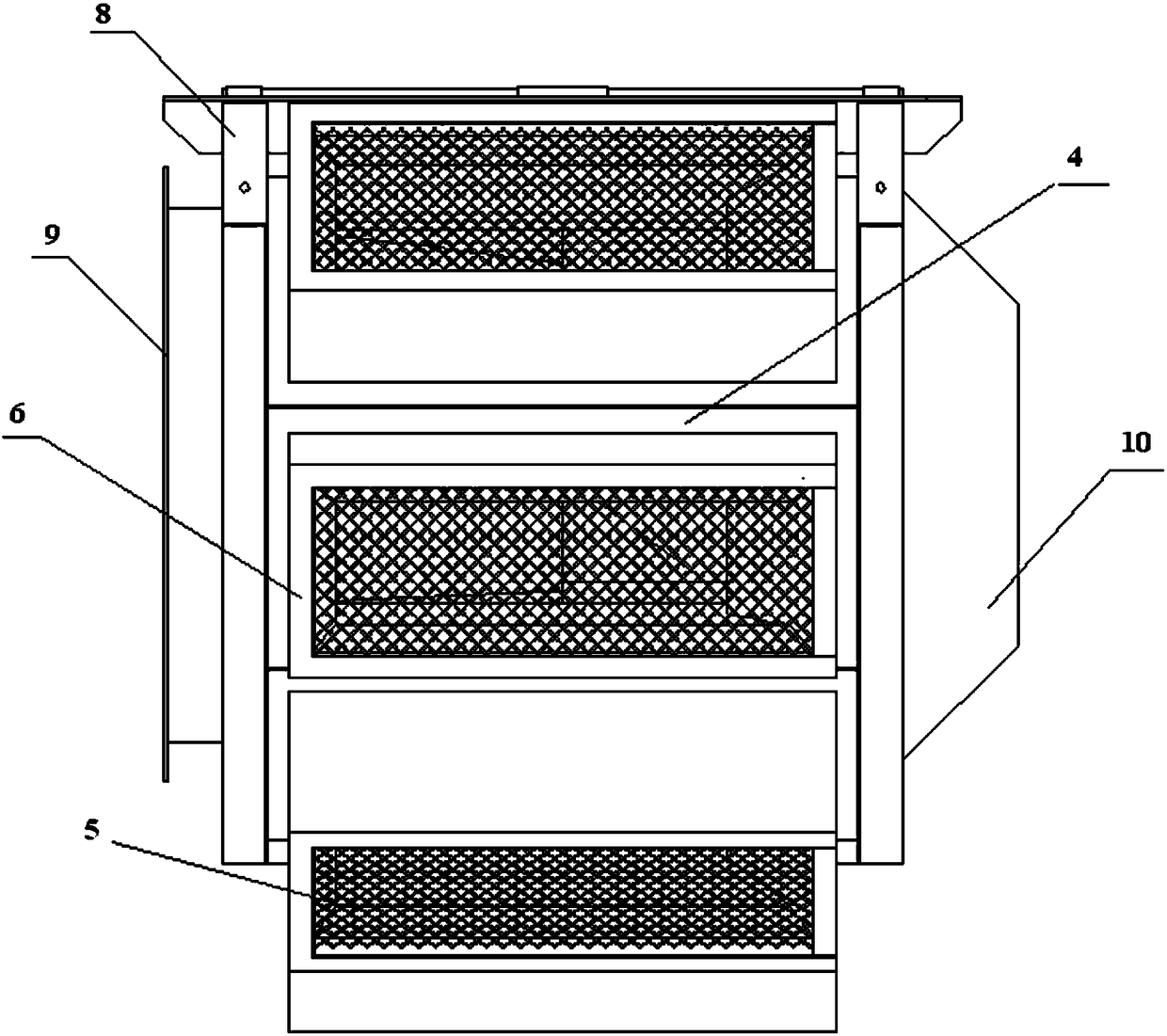

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 with 2 As shown, the present invention provides a muffler for the air inlet of an axial flow fan, which is a cylindrical annular array structure as a whole, and is connected to the air inlet of the axial flow fan, including: a first mounting frame 1, a second mounting frame 8, and a connecting plate 2. Fastening ring 3, cylindrical shell 4, 7 filters 5, 7 muffler boxes 6 and 6 muffler guide inserts 7; the left end face of the cylindrical shell 4 is provided with an end face flange , a round hole is opened in the middle, and it is used as an air inlet channel; the first mounting frame 1 and the second mounting frame 8 are placed oppositely, and the two are connected by the connecting plate 2 to form a ring structure, And sleeved on the outer peripheral wall of the cylindrical shell 4, further fastened by the fastening ring 3; on the outer perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com