Start-up method of dual-series Fischer-Tropsch reactor

The technology of a reaction device and start-up method is applied in the field of start-up of a dual-series Fischer-Tropsch reaction device, which can solve problems such as unfavorable systems, system blockages, and inability to continuously deliver products, so as to ensure product quality, reduce impacts, and ensure consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

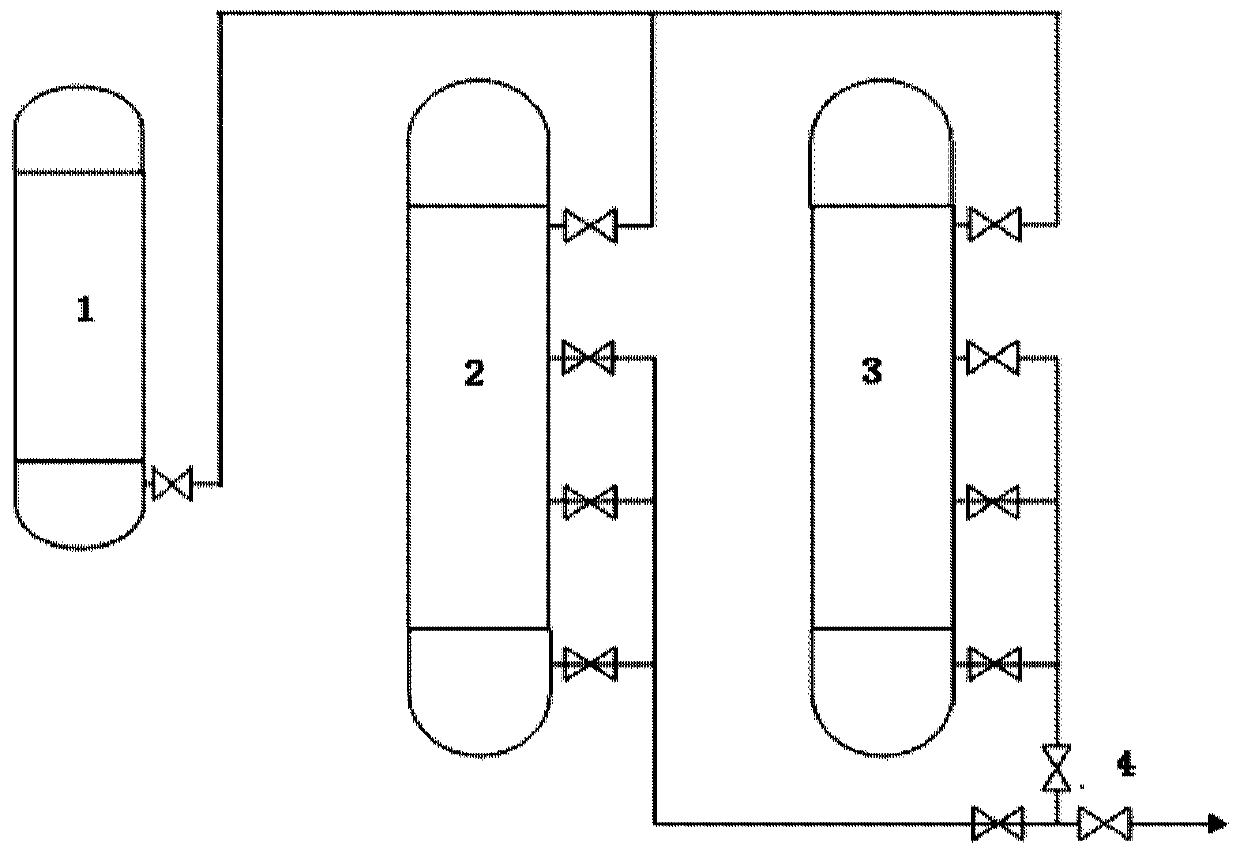

[0043] A start-up method for a dual-series Fischer-Tropsch reaction device. figure 1 It is a schematic diagram of a dual-series Fischer-Tropsch reaction device in an embodiment of the present invention. Such as figure 1 As shown, it includes a reduction reactor 1 , a first synthesis reactor 2 , a second synthesis reactor 3 and a dewaxing filtration unit 4 . Among them, the two synthesis reactors are connected in series; the gasifier is connected with the two synthesis reactors to provide raw material gas for the reaction; the reduction reactor is connected with the two synthesis reactors to provide catalysts for the reaction.

[0044] The start-up method of this two-series Fischer-Tropsch reactor comprises the following steps:

[0045] (1) Nitrogen is introduced into the dual-series Fischer-Tropsch reaction device for air tightness inspection.

[0046] (2) Decrease the pressure to 0.5MPa and start the cycle gas compressor.

[0047] (3) Turn on the drum heating system.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com