Application of mud-resistant slump-retaining type water reducer to machine-made sand concrete prefabricated component

A prefabricated component and concrete technology, which is applied in the field of machine-made sand concrete prefabricated components and mud-resistant and slump-resistant water-reducing agent, can solve the problems of unfavorable concrete pouring concrete structure, compactness, uniformity of concrete strength, large loss of concrete slump over time, Limit the use and promotion of machine-made sand, and achieve the effect of reducing mold turnover cycle, small slump loss, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]An embodiment of the machine-made sand concrete prefabricated component of the present invention, the machine-made sand concrete prefabricated component described in this embodiment includes the following components in parts by weight: 150 parts of water, 380 parts of cement, 40 parts of fly ash, machine-made sand 670 parts, 1120 parts of stones (10-20mm gravel), 10 parts of slump-retaining water reducer (10% solid content).

[0045] The preparation method of the machine-made sand concrete prefabricated component is as follows: the initial body of the prefabricated component formed after concrete pouring is naturally cured to the demoulding strength, and then the mold is demoulded, and then the natural sprinkling and curing is continued to obtain the concrete prefabricated component.

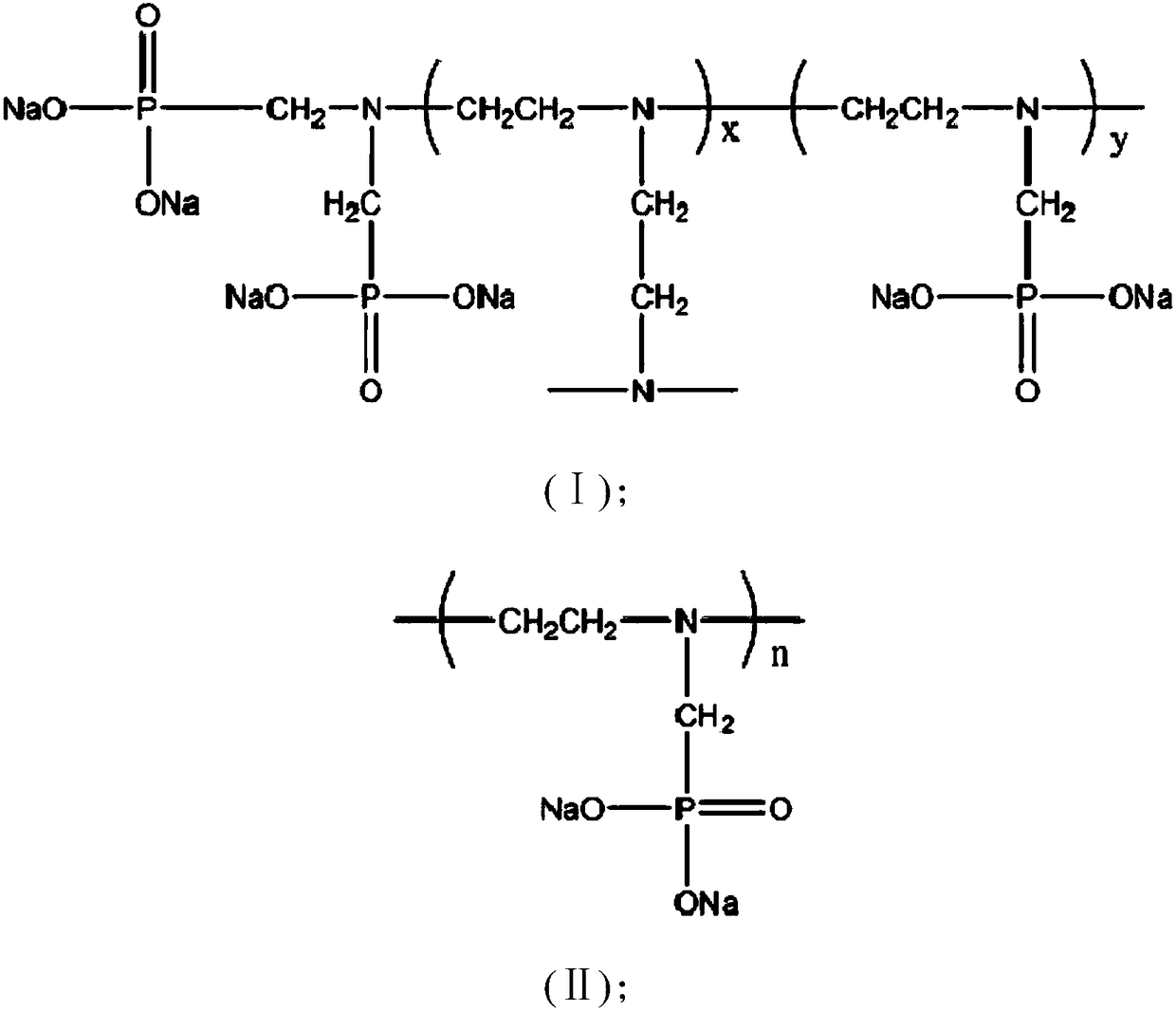

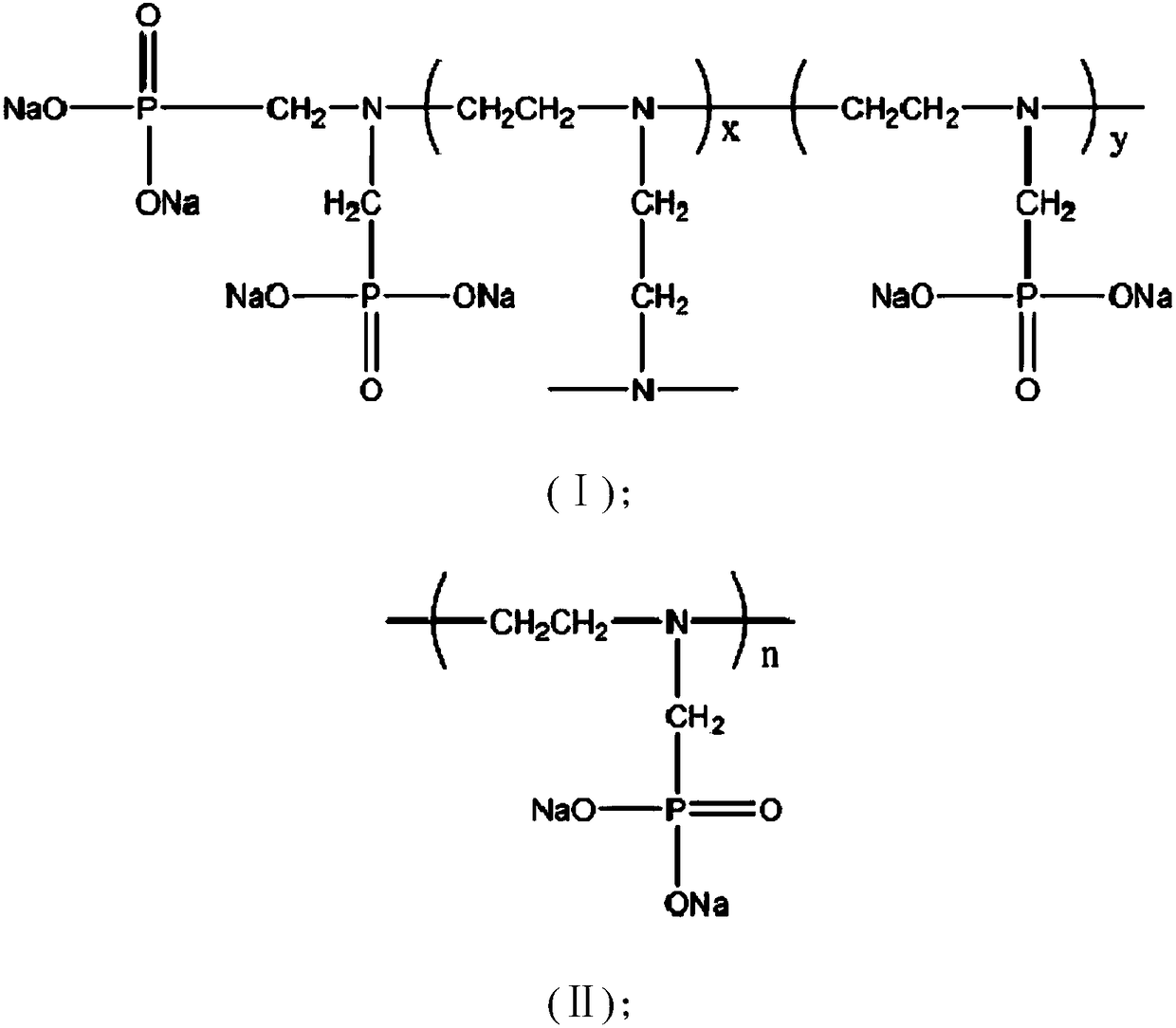

[0046] The mud-resistant and slump-preserving water reducer is prepared by the following method:

[0047] In the 500ml four-neck glass flask with stirrer, thermometer, reflux condenser, ad...

Embodiment 2

[0054] An embodiment of the machine-made sand concrete prefabricated component of the present invention, the machine-made sand concrete prefabricated component described in this embodiment includes the following components in parts by weight: 150 parts of water, 380 parts of cement, 40 parts of fly ash, machine-made sand 670 parts, 1120 parts of stones (10-20mm gravel), 10 parts of slump-retaining water reducer (10% solid content).

[0055] The preparation method of the machine-made sand concrete prefabricated component is as follows: the initial body of the prefabricated component formed after concrete pouring is naturally cured to the demoulding strength, and then the mold is demoulded, and then the natural sprinkling and curing is continued to obtain the concrete prefabricated component.

[0056] The mud-resistant and slump-preserving water reducer is prepared by the following method:

[0057] In the 500ml four-neck glass flask with stirrer, thermometer, reflux condenser, a...

Embodiment 3

[0064] An embodiment of the machine-made sand concrete prefabricated component of the present invention, the machine-made sand concrete prefabricated component described in this embodiment includes the following components in parts by weight: 154 parts of water, 390 parts of cement, 50 parts of fly ash, machine-made sand 680 parts, 1125 parts of gravel (10-20mm gravel), 10.5 parts of slump-preserving water reducer (10% solid content).

[0065] The preparation method of the machine-made sand concrete prefabricated component is as follows: the initial body of the prefabricated component formed after concrete pouring is naturally cured to the demoulding strength, and then the mold is demoulded, and then the natural sprinkling and curing is continued to obtain the concrete prefabricated component.

[0066] The mud-resistant and slump-preserving water reducer is prepared by the following method:

[0067] In the 500ml four-neck glass flask with stirrer, thermometer, reflux condenser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com