Lithium ion battery production process optimization method

A lithium-ion battery and production process technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems that the trolley cannot estimate the transport position, cannot reduce, and cannot reduce the waiting time of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

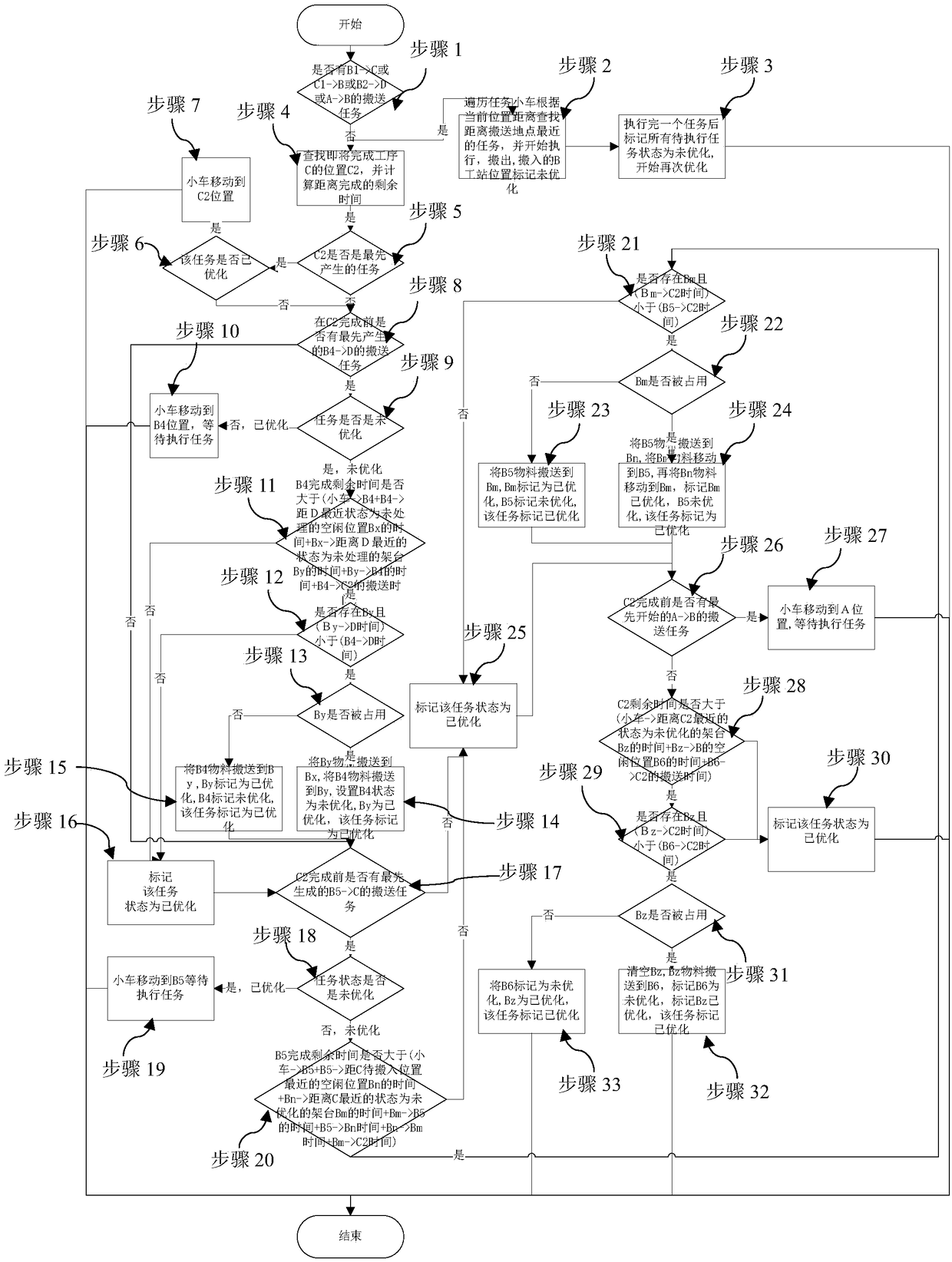

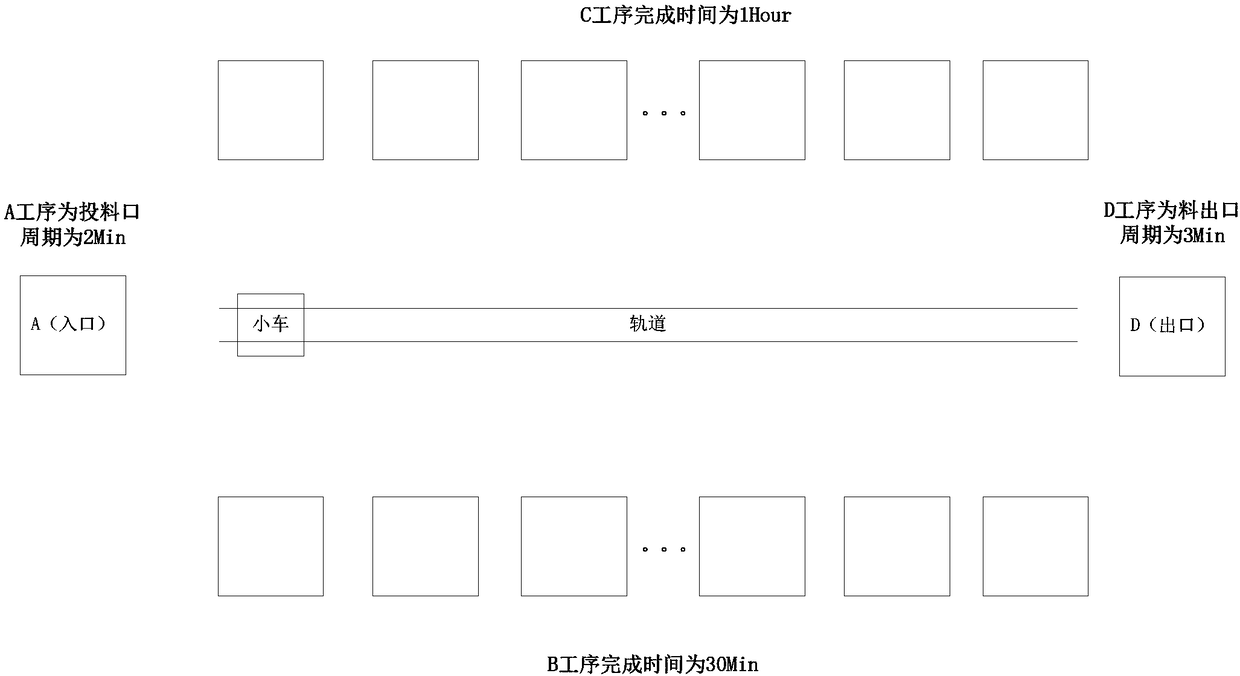

[0058] control figure 2 As shown, the production line has four processes A, B, C, and D. The feeding cycle of A is every 2 minutes, and B has several positions. Every time you enter process B, you need to stand still for 30 minutes before you can go to process C or process D. , C has several devices, each production takes 1 hour, D each production takes 3 minutes, each time the trolley moves in and out of the process, the moving time will be recorded, the production line is:

[0059] A->B; B->C; C->B; B->D;

[0060] Automatically plan the walking route and independently select the transport task. To realize this function, the initial system needs to control the car to perform the following operations to count the transport:

[0061] Transport materials from process A to process B1, B2, B3... storage locations, and count the transport time of the trolley from process A to process B;

[0062] Transport materials from process B1, B2, B3... to process C1, C2, C3... equipment res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com