A method for producing lycopene by B. trispora fermentation and lycopene

A technology of B. trispora and lycopene, which is applied in the field of fermentation engineering, can solve the problems of reducing the metabolic flux of carotenoids, weakening the metabolic flux of lycopene, and high prices of precursor substances, and can eliminate the sugar control process. , cost controllable, simplified operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

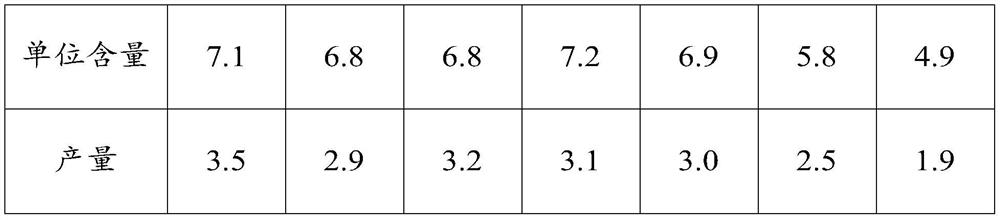

Embodiment 1

[0052] B. trispora positive bacteria and B. trispora negative bacteria were respectively inoculated on the slant surface containing PDA medium, cultured at 28°C for 6 days, then transferred to seed medium, at 28°C, Cultivate for 48 hours under the condition of 220rpm, and feed air at a flow rate of 1.5vvm during the cultivation process.

[0053] The cultured B. trispora positive bacteria and B. trispora negative bacteria were divided into two parts respectively, one part was used for simultaneous inoculation and fermentation with B. trispora of opposite sex, and the other part continued to be cultured. Wherein, the simultaneous inoculation is to inoculate the cultured B. trispora positive bacteria and B. trispora negative bacteria in a weight ratio of 1:5 in a fermenter containing a fermentation medium. The biomass dry weight of B. trispora positive bacteria and B. trispora negative bacteria were both 15g / L at the time of inoculation.

[0054] Simultaneously after the inocula...

Embodiment 2

[0060] B. trispora positive bacteria and B. trispora negative bacteria were respectively inoculated on the slope containing PDA medium, cultured at 26°C for 8 days, then transferred to seed medium, and grown at 26°C, Cultivate for 52 hours under the condition of 200rpm, and feed air at a flow rate of 1vvm during the cultivation process.

[0061] The cultured B. trispora positive bacteria and B. trispora negative bacteria were divided into two parts respectively, one part was used for simultaneous inoculation and fermentation with B. trispora of opposite sex, and the other part continued to be cultured. Wherein, the simultaneous inoculation is to inoculate the cultured B. trispora positive bacteria and B. trispora negative bacteria in a weight ratio of 1:3 in a fermenter containing a fermentation medium. The biomass dry weight of B. trispora positive bacteria and B. trispora negative bacteria was 12g / L at the time of inoculation.

[0062] Simultaneously after the inoculation, ...

Embodiment 3

[0068] B. trispora positive bacteria and B. trispora negative bacteria were respectively inoculated on the slant surface containing PDA medium, cultured at 30°C for 4 days, then transferred to seed medium, at 30°C, Cultivate for 44 hours under the condition of 240rpm, and feed air at a flow rate of 2vvm during the cultivation process.

[0069] The cultured B. trispora positive bacteria and B. trispora negative bacteria were divided into two parts respectively, one part was used for simultaneous inoculation and fermentation with B. trispora of opposite sex, and the other part continued to be cultured. Wherein, the simultaneous inoculation is to inoculate the cultured B. trispora positive bacteria and B. trispora negative bacteria in a weight ratio of 1:7 in a fermenter containing a fermentation medium. The biomass dry weight of B. trispora positive bacteria and B. trispora negative bacteria was 10g / L at the time of inoculation.

[0070] Simultaneously after the inoculation, fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com