A kind of azeotropic rectification heat coupled polyoxymethylene dimethyl ether synthesis reaction system

A polymethoxydimethyl ether and azeotropic distillation technology, which is applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of low product yield, etc., and achieve high reaction yield and low energy. The effect of reducing consumption and investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

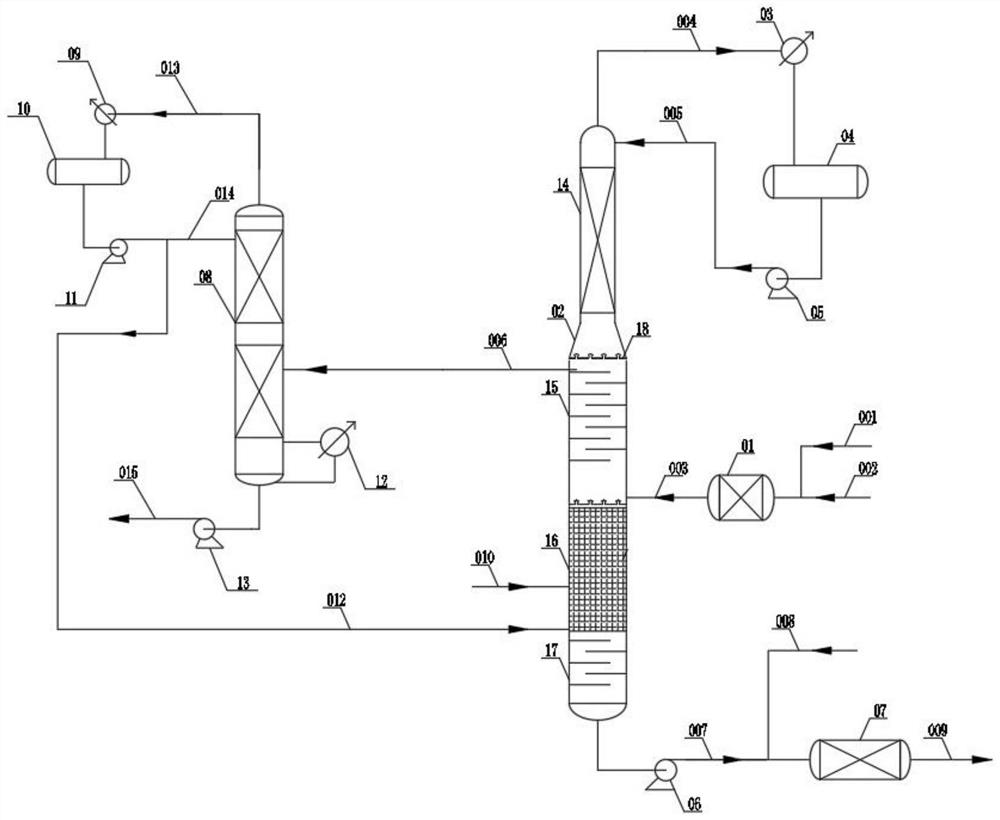

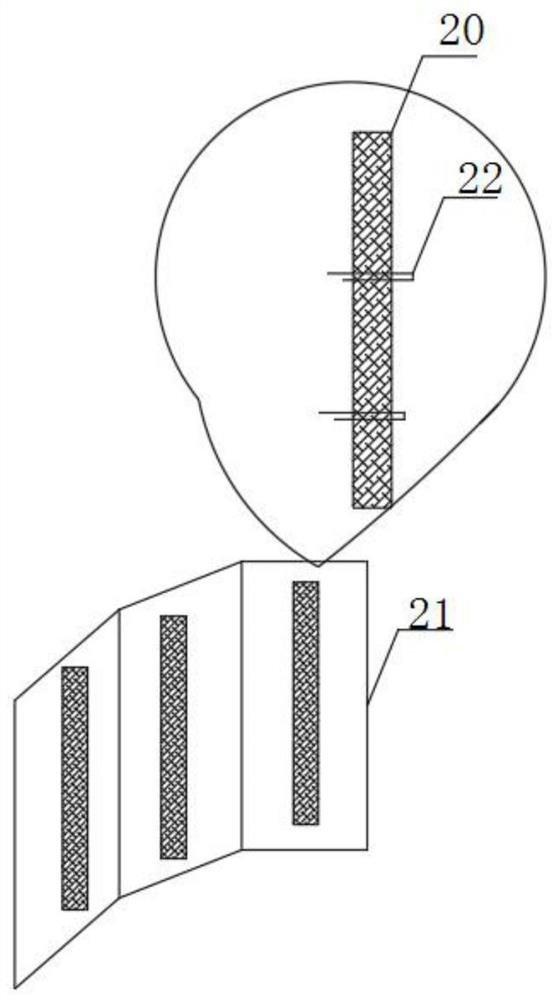

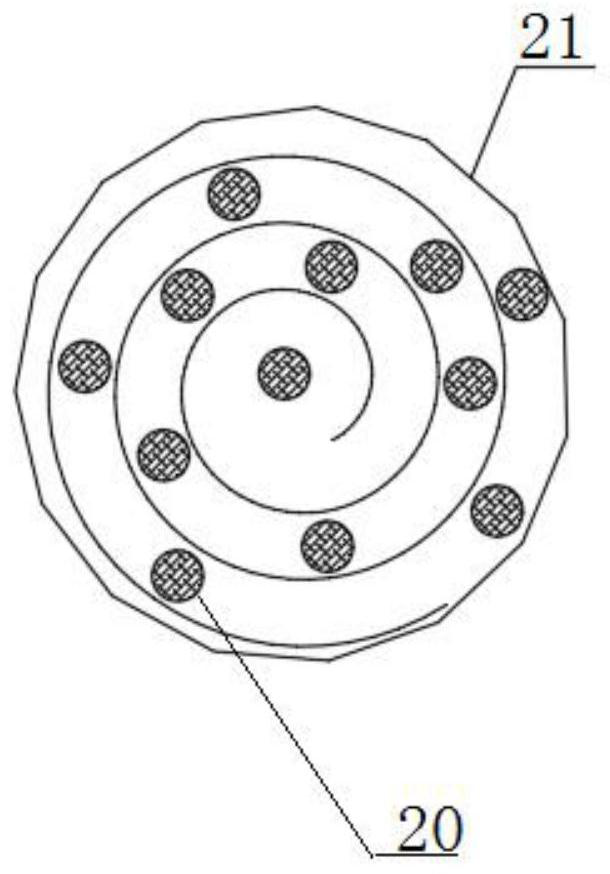

[0037] like Figure 1-3 As shown, 01 is the pre-reactor, 02 azeotropic distillation reactor and 08 methylal refining tower.

[0038] The reaction raw materials formaldehyde aqueous solution (stream 001) and methylal (stream 002) are mixed according to a reasonable mass ratio (such as 1:1-1:10) and preheated to 55-120 ° C and then pumped into the pre-reactor 01; Conditions (55-120°C, pressure 0.3-1.0MPA). The raw material formaldehyde and methylal stream feed are shown in Table 1.

[0039] Table 1: Components of Stream 001 and Stream 002

[0040]

[0041] The main reaction of the pre-reactor is the decomposition reaction of methylal:

[0042]H2O+CH3OCH2OCH3CH2O+2CH3OH△H<0

[0043] It can be seen from the above formula that the reaction is an endothermic reversible reaction, and increasing the reaction temperature is conducive to the positive shift of the equilibrium.

[0044] The composition of raw formaldehyde and methylal after the reaction in the prereactor is stream...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com