Rapid heavy metal-contaminated slurry dewatering system and method for rapid heavy metal-contaminated slurry dewatering

A heavy metal sludge and rapid dehydration technology, which is applied in dehydration/drying/thickened sludge treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of reducing dehydration effect, unfavorable particle compression, long dehydration cycle, etc. problems, to achieve the effect of improving dehydration effect, improving dehydration performance, and low moisture content of mud cake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

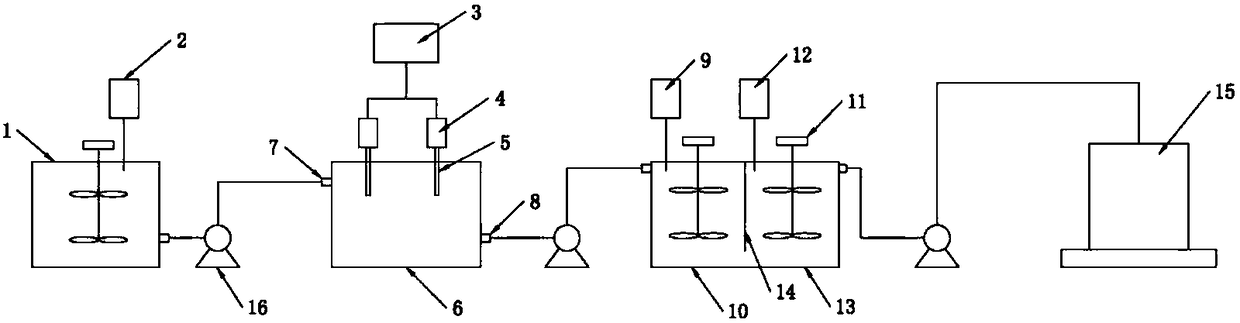

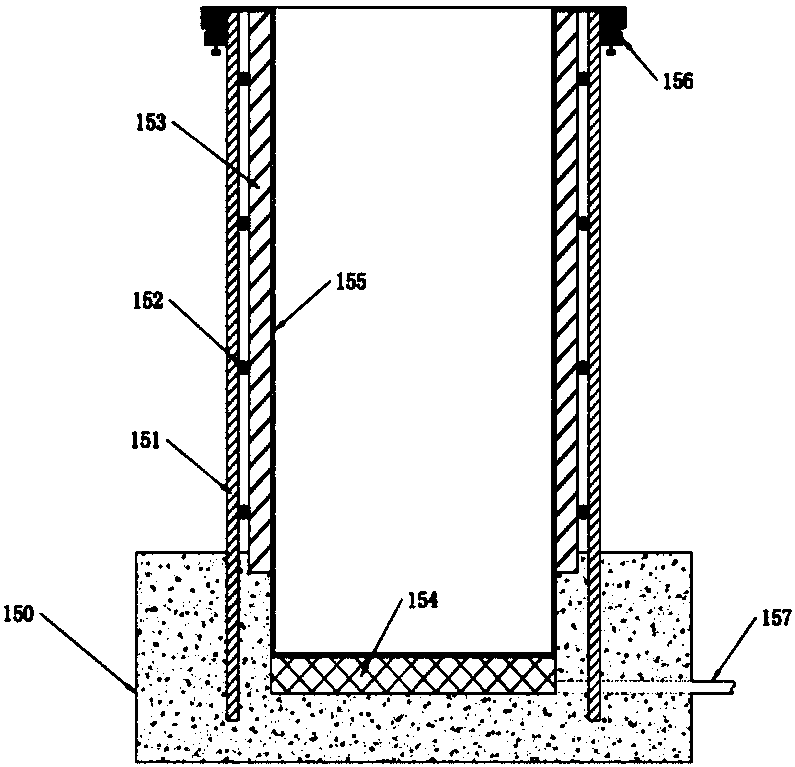

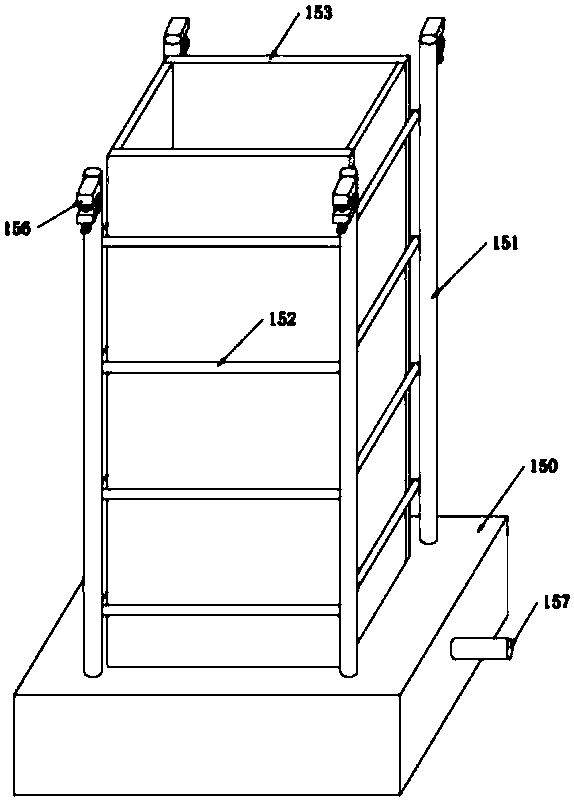

Method used

Image

Examples

Embodiment 1

[0050] The heavy metal contaminated soil left over from a chemical plant in Hengyang City was treated with the leaching method to produce mud with a moisture content of 98%. The mud was enriched with heavy metals leached from the soil, mainly cadmium (Cd), lead (Pb), Zinc (Zn), Arsenic (As). Add lime to the sludge temporary storage tank to adjust the pH to 9, then send the mud into the ultrasonic reaction device, the ultrasonic generator does not start (that is, no ultrasonic action is applied), and then pump it into the flocculation reaction device, and add 10 to the flocculation tank respectively. % of polyferric sulfate and 5‰ (mass ratio, sludge dry weight) cationic polyacrylamide, stir evenly and then pump into the sludge dewatering device, stop filling after the geotechnical tube bag is filled, and wait until the moisture in the sludge After flowing out, leave a space on the upper part of the geotechnical tube bag and continue filling, repeat filling 4 to 6 times until c...

Embodiment 2

[0052] The implementation method is the same as in Example 1, the ultrasonic generator is turned on, and the ultrasonic wave with a frequency range of 28kHz and a sound energy density of 0.1W / mL is applied for 6s. Change the flocculant addition to 5% polyferric sulfate and 2‰ (mass ratio, sludge dry weight) cationic polyacrylamide. The sludge was dehydrated in geotube bags for 10 days, with an average moisture content of 48%.

Embodiment 3

[0054] The implementation method is the same as in Example 2, but the sequence of ultrasonic wave and flocculation is changed. After the sludge is adjusted to pH 9, it first enters the flocculation reaction device, and 5% polyferric sulfate and cations of 2‰ (mass ratio, sludge dry weight) are added. Type polyacrylamide, and then subjected to ultrasonic waves with a frequency range of 28kHz and a sound energy density of 0.1W / mL for 6s. The sludge is dehydrated in geotube bags for 10 days with an average moisture content of 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com