Wheel-side electric driving system with dynamic vibration absorbing function

An electric drive system, wheel edge technology, applied in motion deposition, power devices, steering mechanisms, etc., can solve problems such as interference, improve dynamic performance, inhibit the increase of unsprung mass, and increase flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

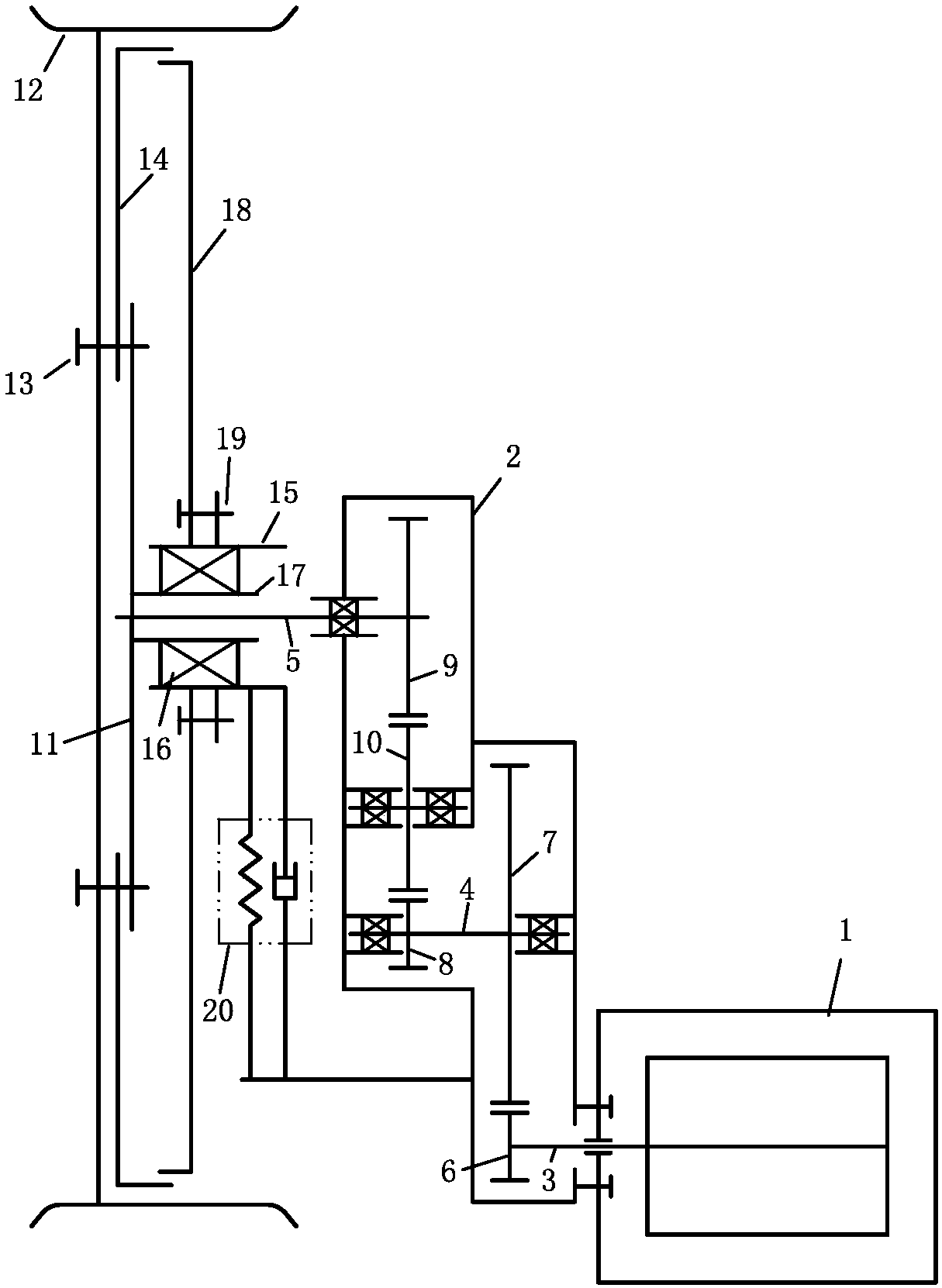

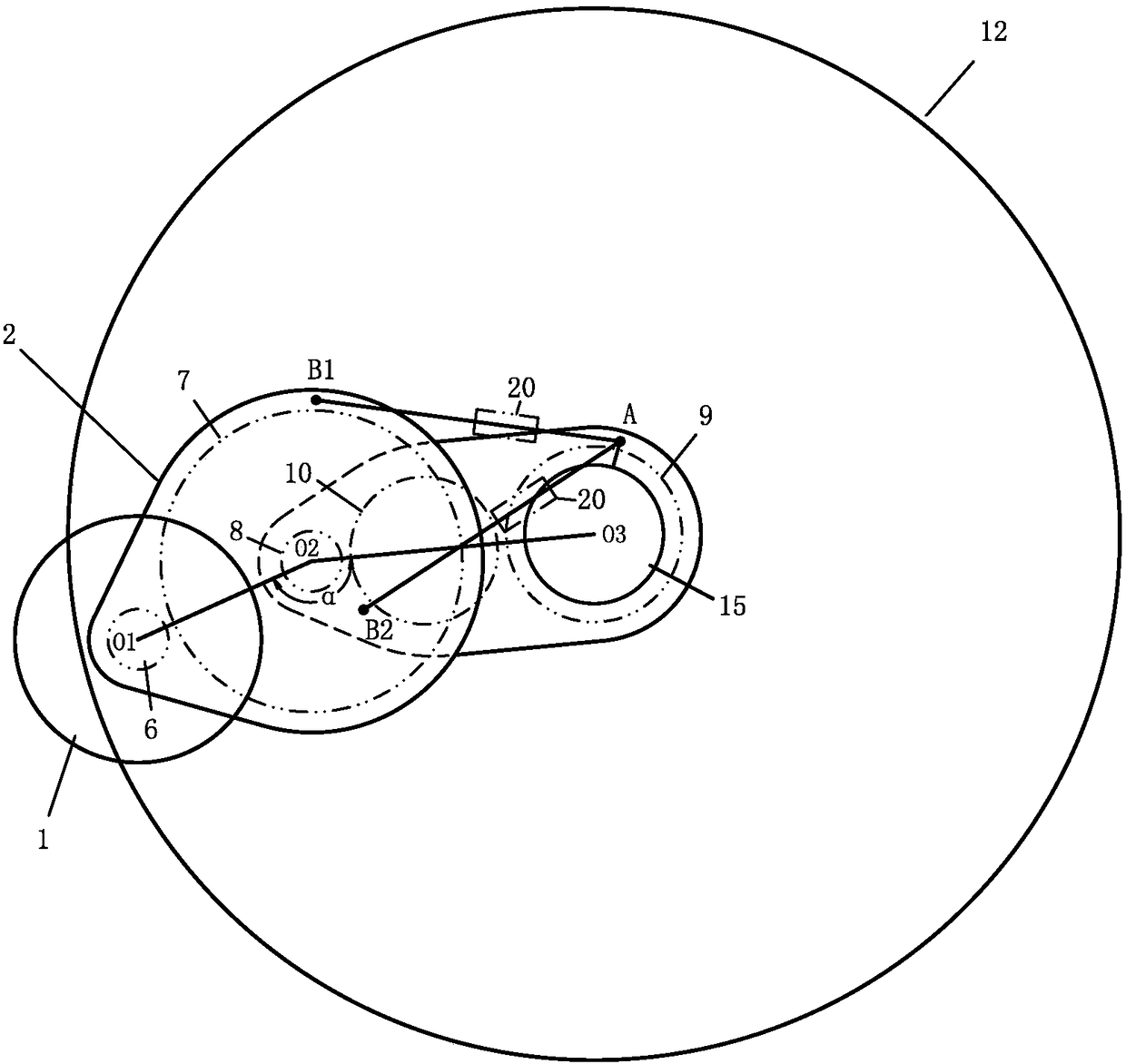

[0023] A feasible implementation of the wheel-side electric drive system with dynamic vibration absorption function of the present application will be described below with reference to the accompanying drawings. It should be pointed out that the drawings provided here are only exemplary, and do not constitute any limitation to the scope of the application. In order to highlight certain features, the various parts in the drawings are not drawn to scale, and some structures are schematically shown with dotted lines, and some structures are omitted and not shown.

[0024] figure 1 , schematically shows a wheel-side electric drive system with a dynamic vibration-absorbing function according to a possible embodiment of the present application. Each drive wheel of the vehicle is equipped with a wheelside electric drive system, in which the output rotational motion and torque of the motor 1 arranged on the side of the wheel close to the drive wheel is transmitted to the wheel throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com