Automatic engraving machine and engraving method

A grinding and automatic technology, which is applied to machine tools, grinding machines, grinding/polishing equipment, etc., which are suitable for grinding workpiece planes, can solve the problems of poor positioning and machining accuracy, complex structure, etc., and achieve improved machining accuracy and simple operation , The effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

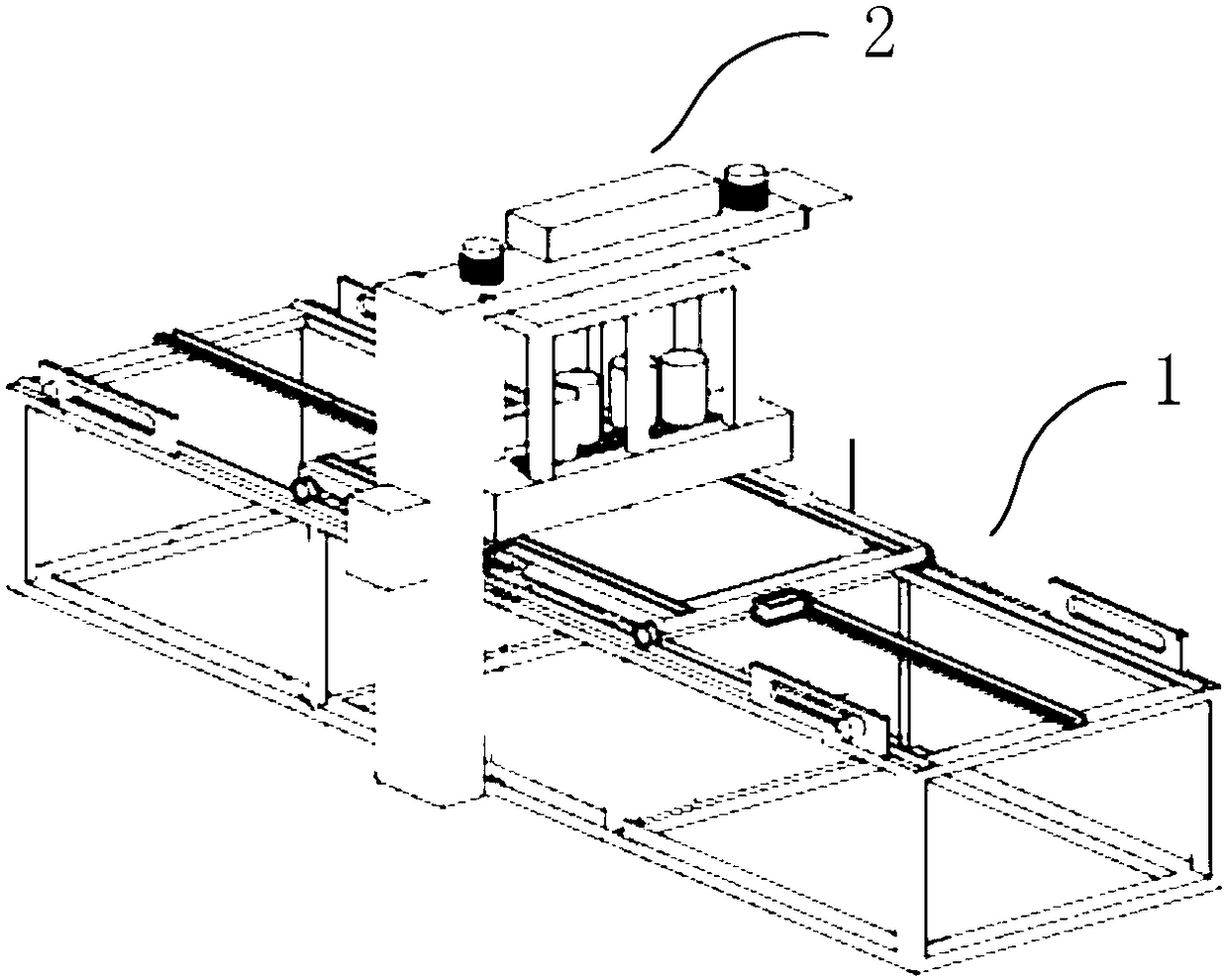

[0040] Specific implementation mode one: see figure 1 with figure 2 Describe this embodiment, an automatic grinding machine described in this embodiment, including a controller, a horizontal moving part 1 and a processing part 2;

[0041] The controller is used to control the horizontal moving part 1 to move forward and backward in the horizontal direction, and is also used to control the processing part 2 to move up and down in the vertical direction, so that the processing part 2 can process the workpiece to be processed on the horizontal moving part 1. processing;

[0042] Both the processing part 2 and the horizontal moving part 1 are provided with limit switches 5, and the limit switches 5 are used to sense the limit positions of the processing part 2 and the horizontal moving part 1, and upload them to the controller.

[0043] In this embodiment, the automatic grinding machine is simple in structure, and the introduction of the limit switch 5 accurately limits the mov...

specific Embodiment approach 2

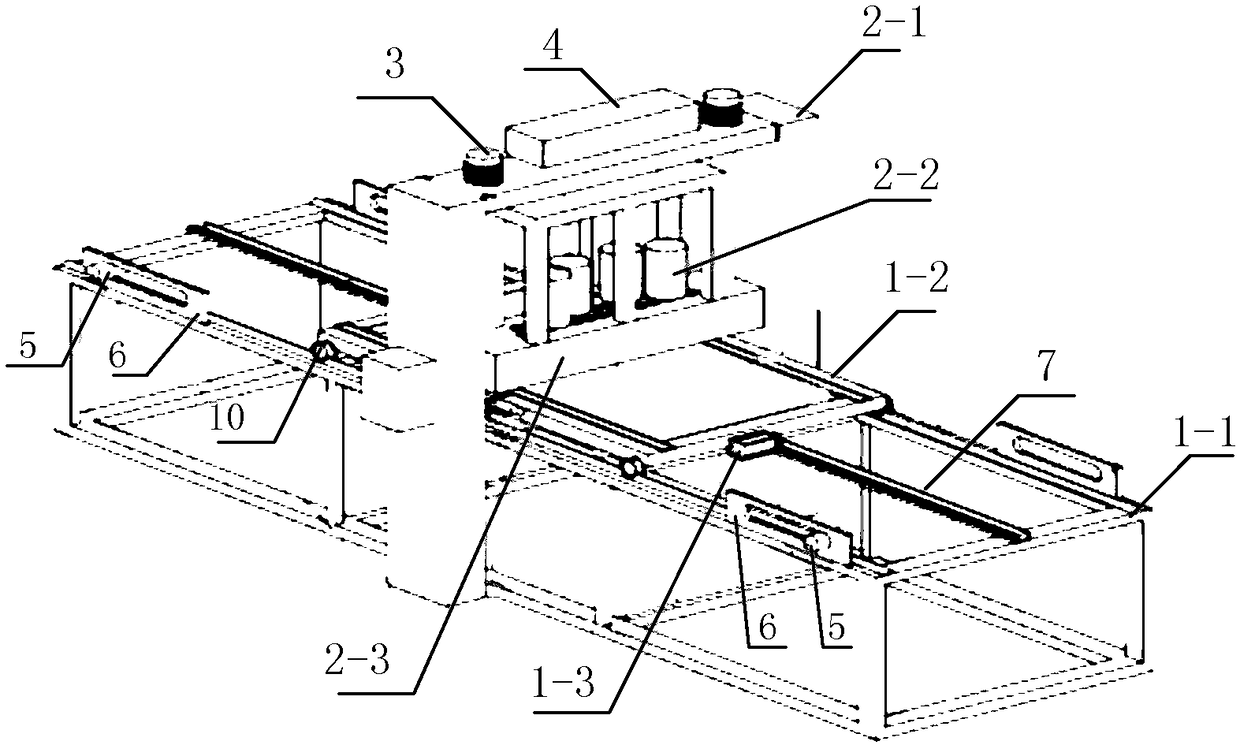

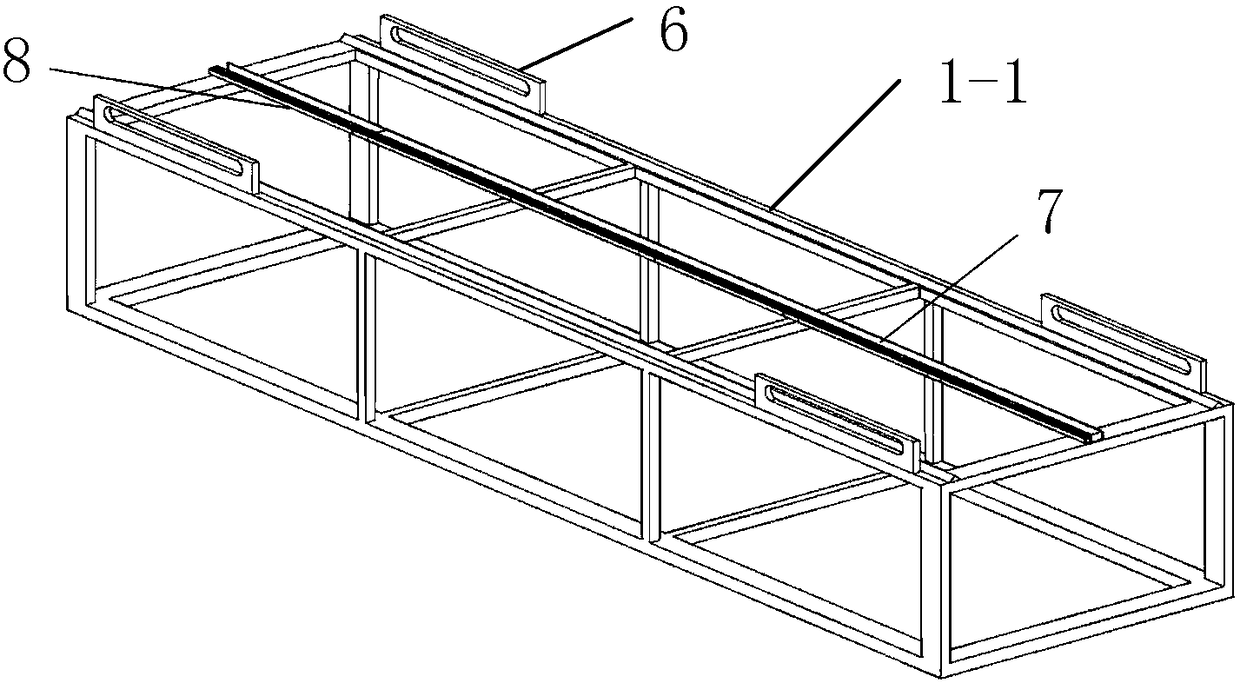

[0044] Specific implementation mode two: see Figure 1 to Figure 4 Describe this embodiment. The difference between this embodiment and the automatic grinding machine described in Embodiment 1 is that the horizontal moving part 1 includes a base 1-1, a workbench 1-2, and a stepping motor 1-3;

[0045] The workbench 1-2 is slidingly connected with the two slide rails on the base 1-1 through the roller 10;

[0046] The stepper motor 1-3 is used to drive the workbench 1-2 to move forward and backward along the two slide rails on the base 1-1.

[0047] In this embodiment, the horizontal moving part 1 has a simple structure and is easy to operate.

specific Embodiment approach 3

[0048] Specific implementation mode three: see Figure 1 to Figure 5 Describe this embodiment, the difference between this embodiment and the automatic grinding machine described in the second embodiment is that the processing part 2 includes a faucet frame 2-1, N AC motors 2-2 and a gear box 2-3;

[0049] The faucet frame 2-1 is a door-shaped structure, and straddles the top of the horizontal moving part 1;

[0050] The gear box 2-3 is fixed on the beam of the faucet frame 2-1 through the spring column 3;

[0051] The faucet frame 2-1 is also provided with an air pump 4, which is used to control the gear box 2-3 to move up and down between the beam of the faucet frame 2-1 and the workbench 1-2;

[0052] N AC motors 2-2 are fixed on the gear box 2-3, and the N AC motors 2-2 drive the grinding head 9 to rotate through the gear box 2-3, and the grinding head 9 is used to process the workpiece on the horizontal moving part 1 parts for processing;

[0053] N is an integer great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com