Spray nozzle for spray painting apparatus

A technology for spraying devices and coatings, which is applied in spraying devices, spraying devices, spraying devices with movable outlets, etc., can solve the problems of coating particleization treatment limitations, paint pollution, and low atomization efficiency, and achieve improved particleization efficiency, Effect of improving cleaning efficiency and improving coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the drawings.

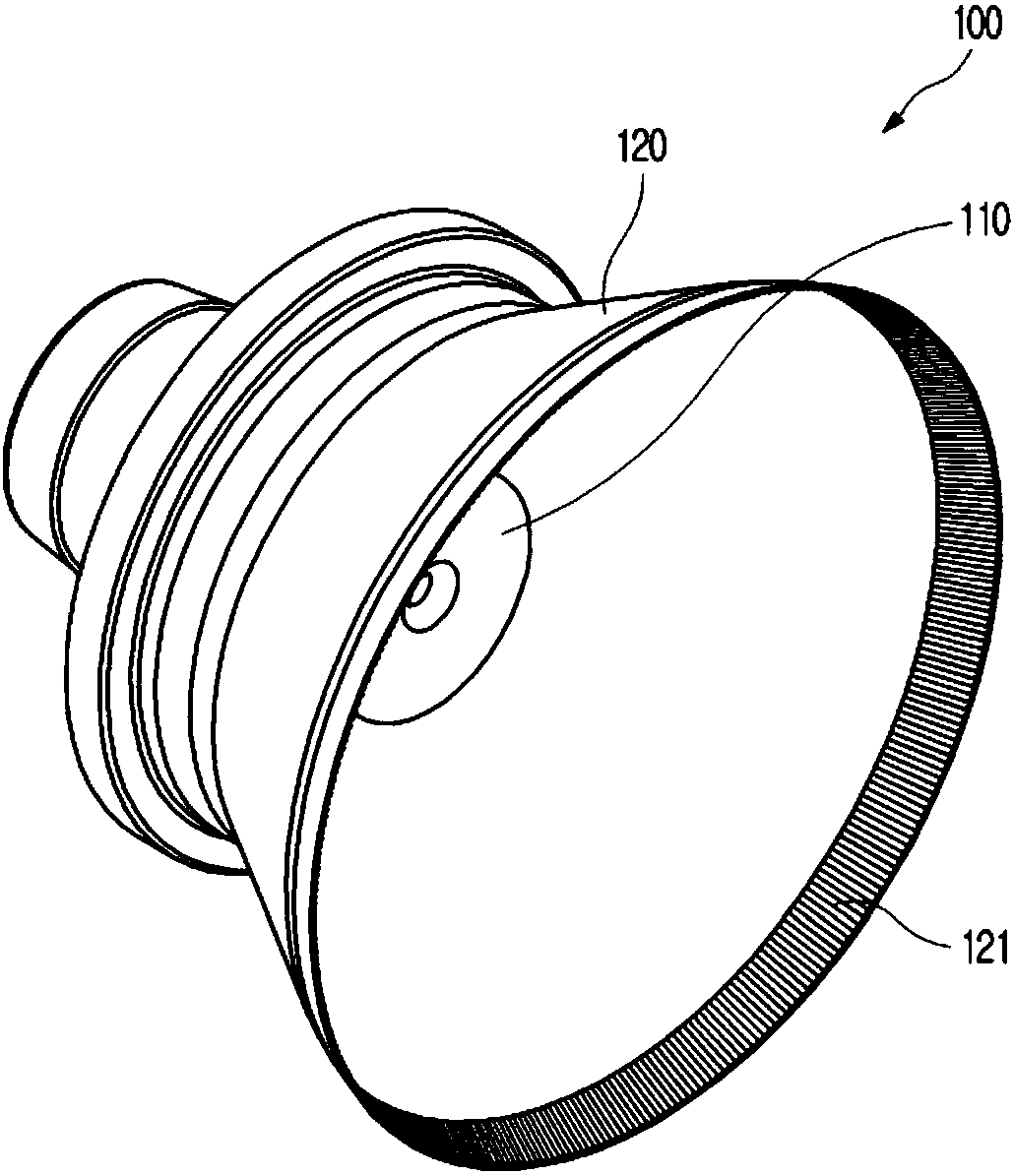

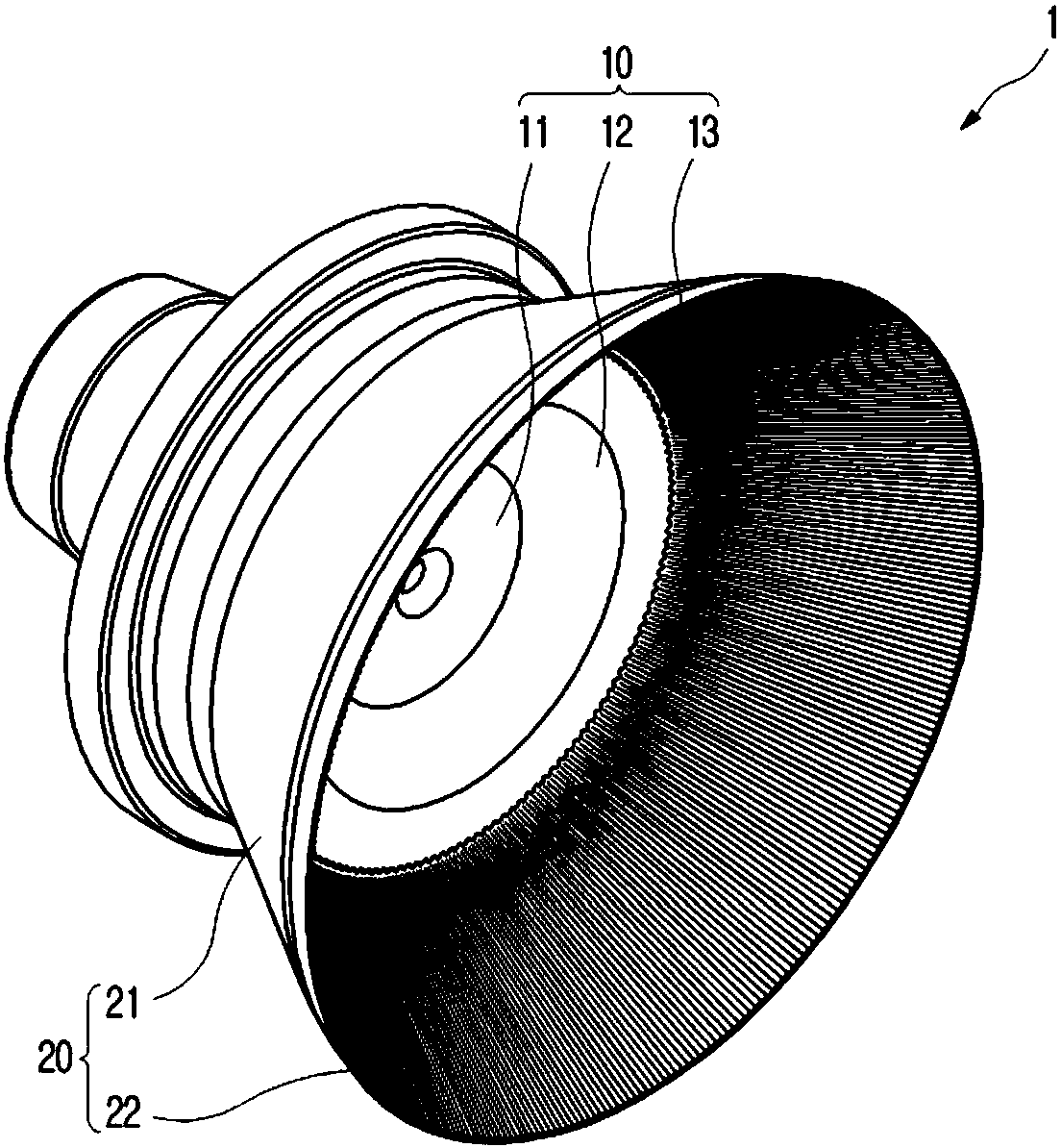

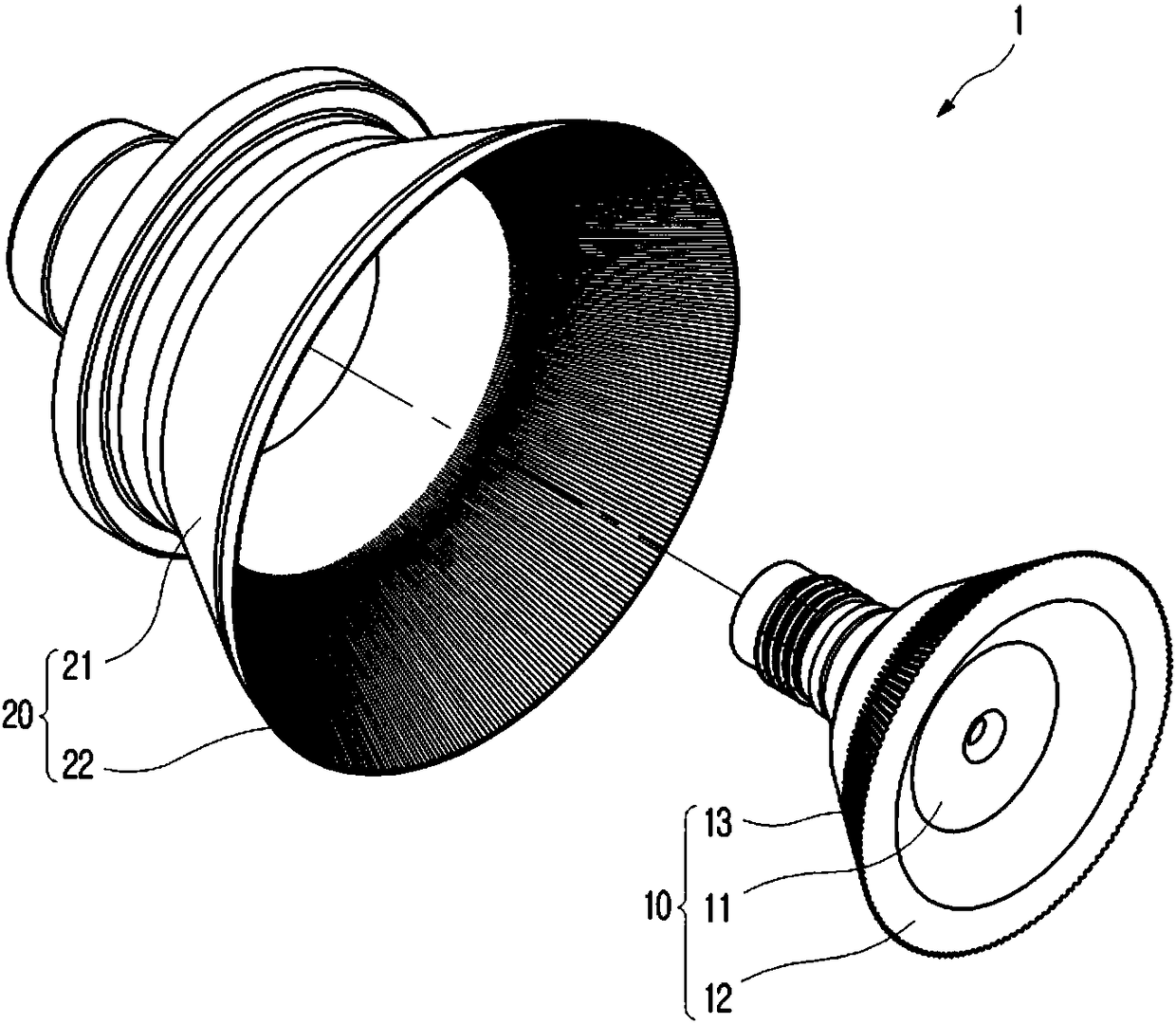

[0035] figure 2 Is a bottom perspective view of a nozzle for a paint spraying device according to an embodiment of the present invention, image 3 Is a perspective view of a rotating dispersion unit according to an embodiment of the present invention, Figure 4 It is a cross-sectional view of a nozzle for a paint spraying device according to an embodiment of the present invention.

[0036] Such as Figure 2 to Figure 4 As shown, the nozzle 1 for a paint spraying device according to an embodiment of the present invention includes a rotating dispersion unit 10 and a rotating atomizing unit 20.

[0037] The rotating dispersing unit 10 includes: a rotating main body 11 provided on the inner side of the rotating atomization unit 20 to be described later; an extension portion 12 extending outwardly from the end of the rotating main body 11; and protruding forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com