Leaf crushing and drying equipment for garden maintenance

A technology for drying equipment and leaves is applied in the field of leaf crushing and drying equipment for garden maintenance, which can solve the problems of incomplete dehydration of leaves and unfavorable transportation of scraps, and achieve the effects of protecting normal operation, flexible use and reducing the weight of leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

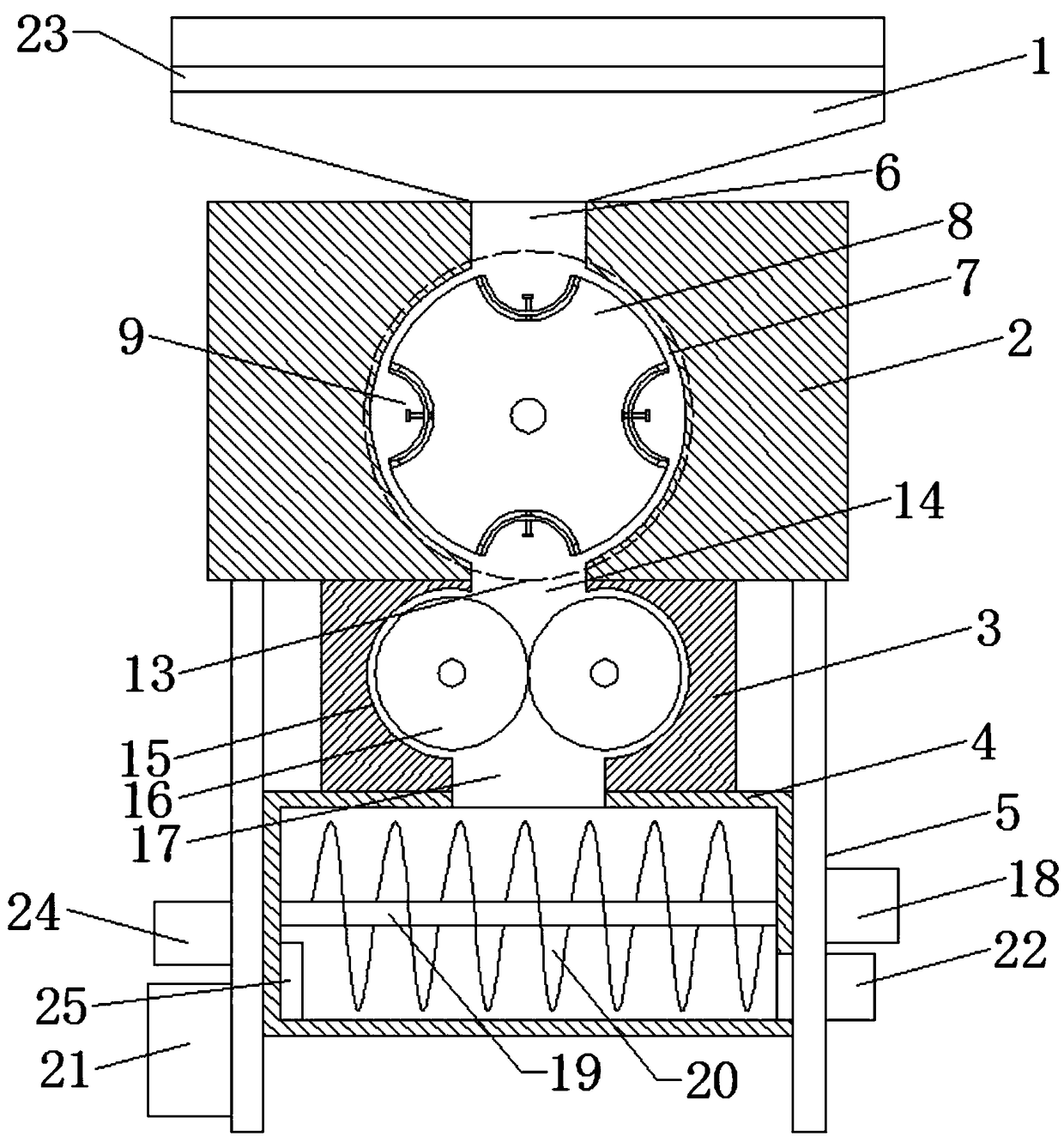

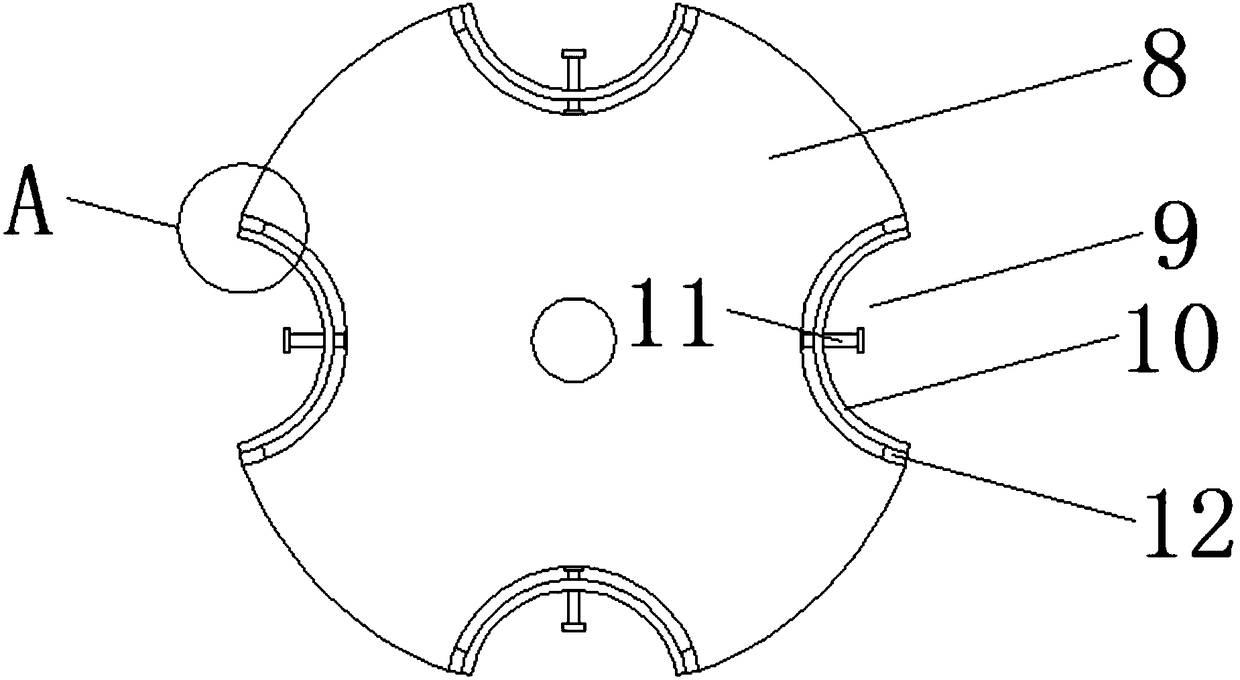

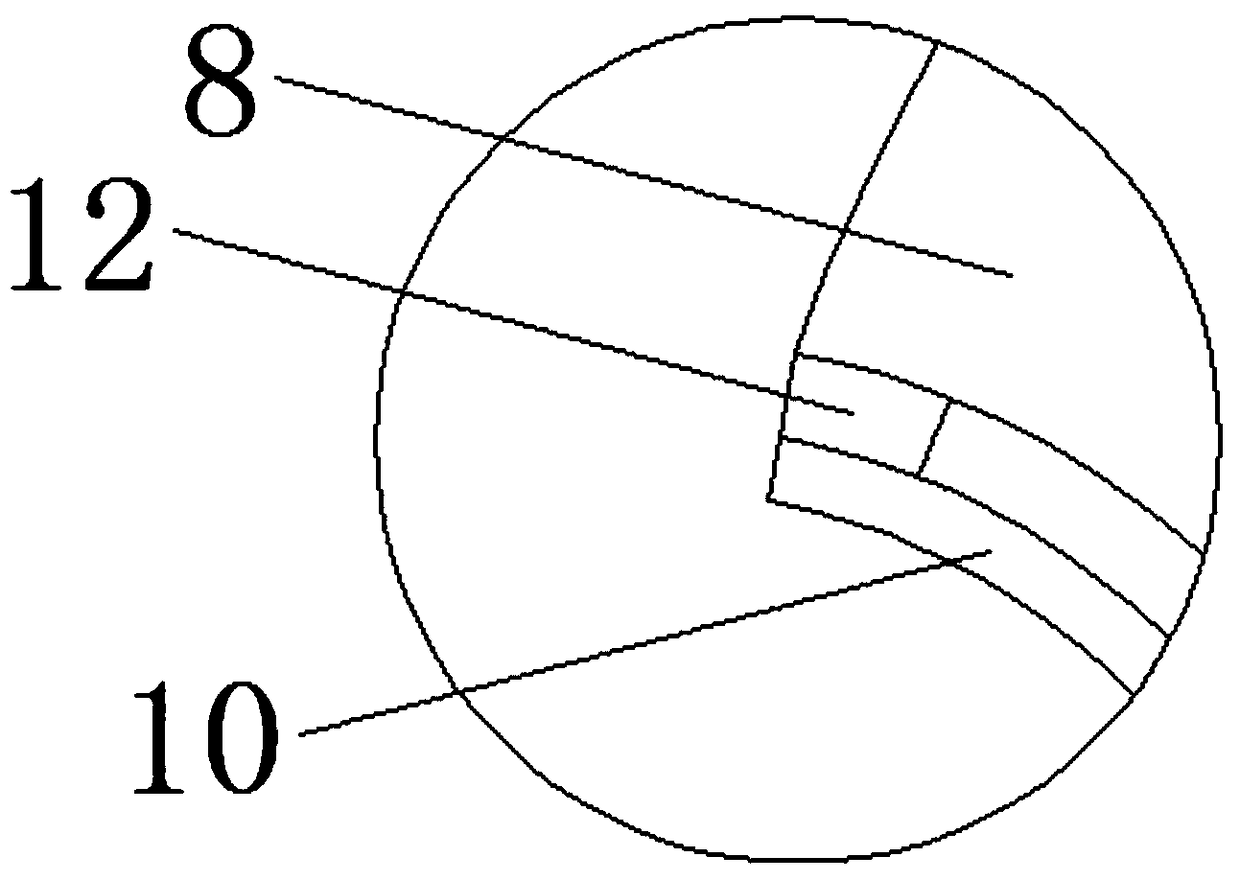

[0021] Please refer to the figure, in the embodiment of the present invention, a leaf crushing and drying equipment for garden maintenance includes a feed hopper 1, a fixed seat 2, a crushing box 3, a drying box 4 and a bracket 5; the lower part of the fixed seat 2 Supports 5 are fixed on the four corners of the side, the feed hopper 1 is located at the upper end of the fixed seat 2, the crushing box 3 is fixed at the lower end of the fixed seat 2, and the drying box 4 is fixed at the lower end of the crushed box 3; The opening faces upwards, and a horizontal protective net 23 is fixed in the feed hopper 1. The protective net 23 is composed of a plurality of rods equidistantly distributed, and prevents people's arms from extending into the feed hopper 1 through a plurality of rods to protect personnel. It is safe and convenient to disperse the leaves for feeding.

[0022] On the fixing seat 2 corresponding to the lower end of the feeding hopper 1, a feeding port 6 is provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com