Special collar cleaning equipment capable of automatically discharging detergent

A technology for cleaning equipment and detergents, applied in applications, household appliances, brushes, etc., can solve the problems of low degree of automation, lack of automatic dispensing of detergents, etc., and achieve the effect of high degree of automation, easy equipment operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

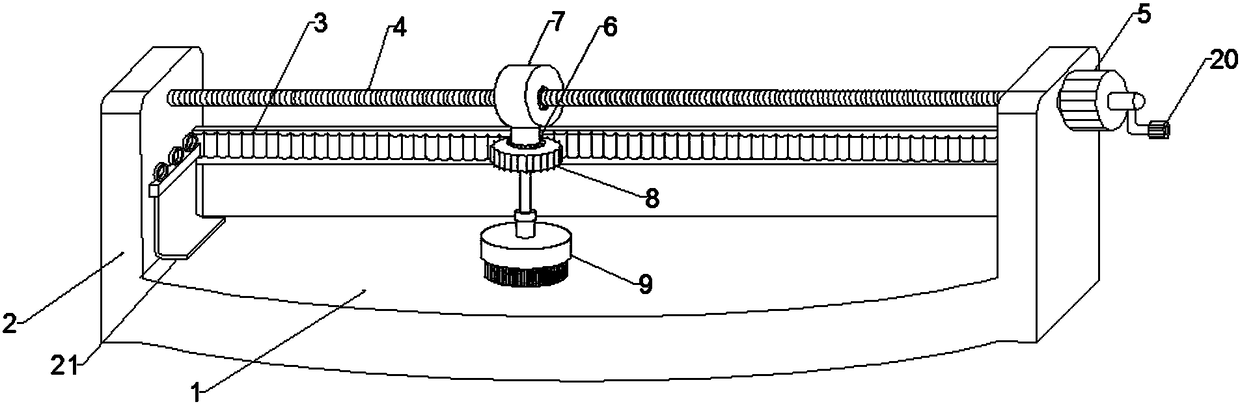

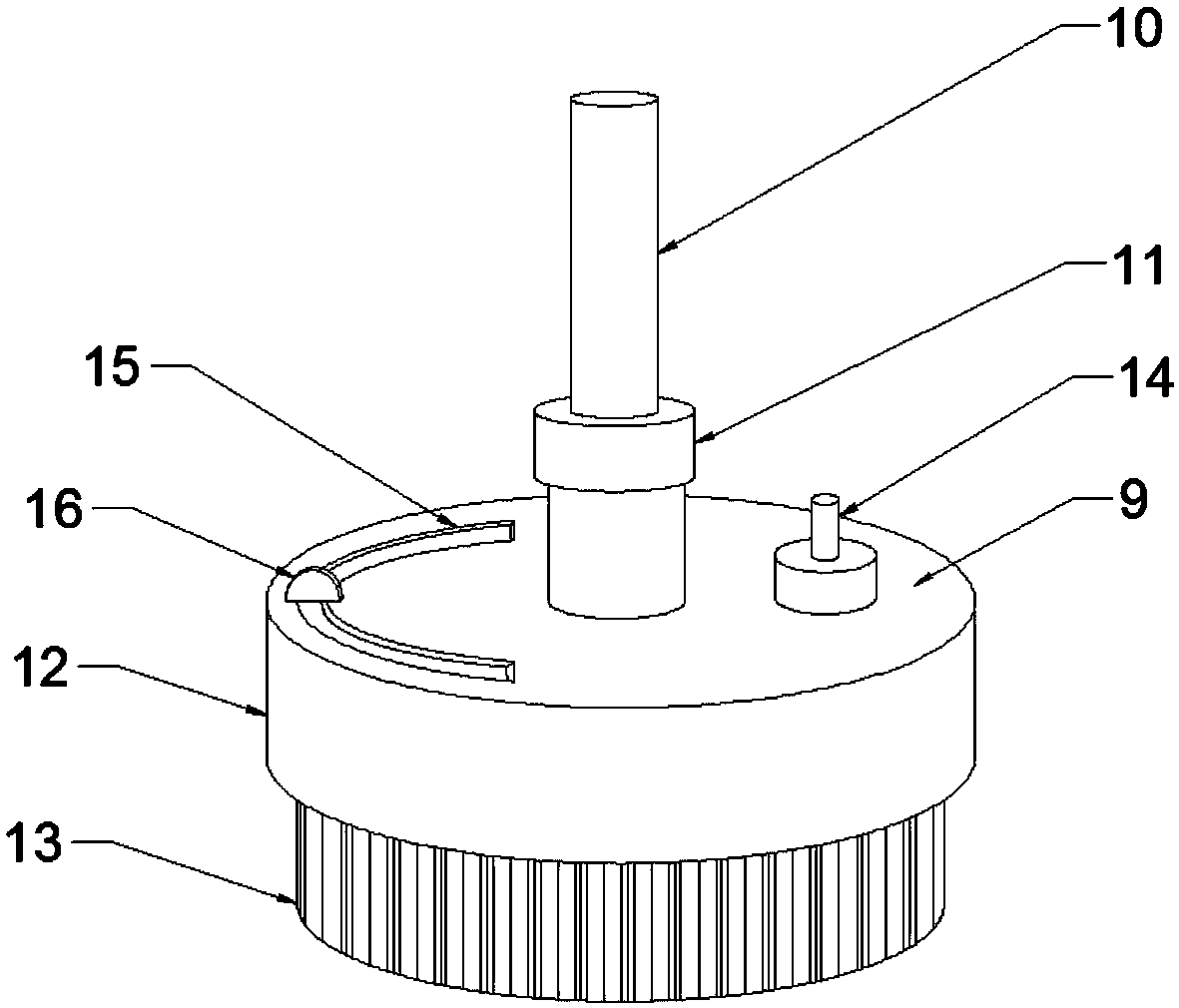

[0029] Such as Figure 1-4 As shown, a special collar cleaning device that can automatically discharge detergent includes a base 1, and support frames 2 are provided at both ends of the base 1, and a connecting shaft 3 and a connecting shaft 2 are connected between the two support frames 2. The rotating shaft 4 is connected, and one end of the rotating shaft 4 extends out of the support frame 2 and is connected with a drum 5, and the rotating shaft 4 is provided with a cleaning device 6, and the cleaning device 6 includes a rotating drum 7 sequentially connected from top to bottom , runner 8 and rotating brush 9;

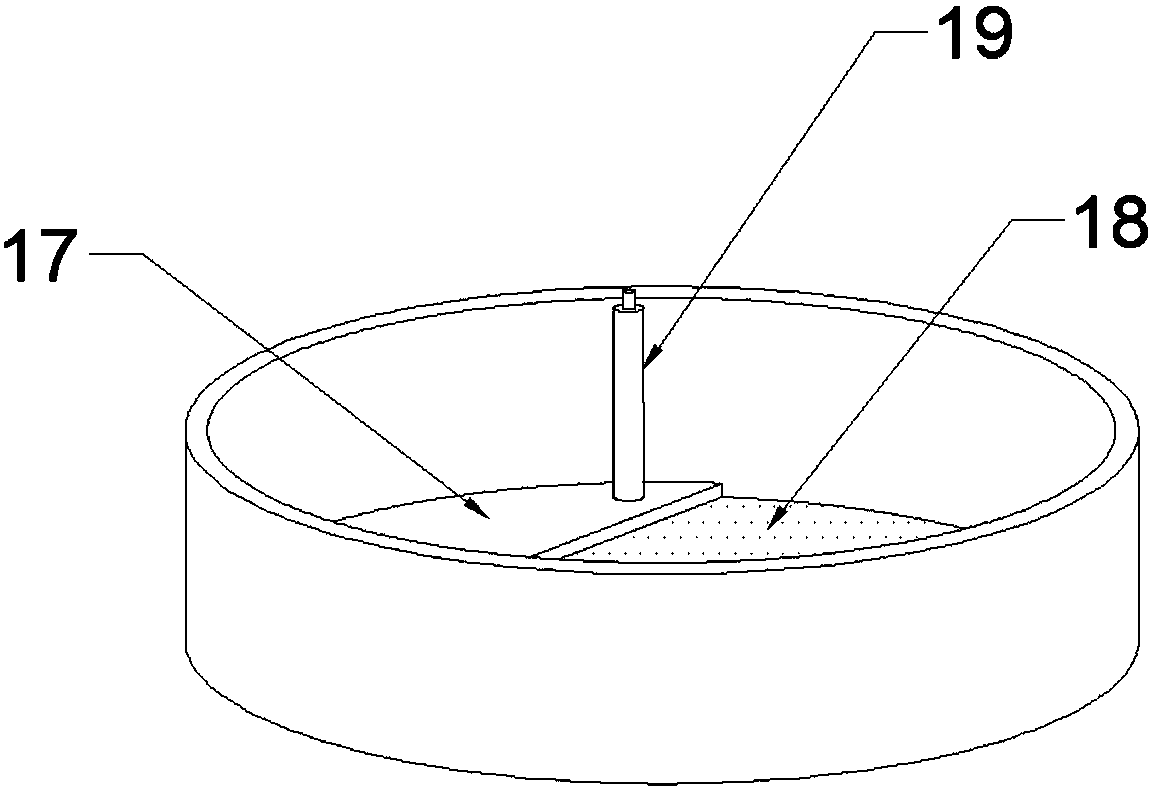

[0030] The rotating brush 9 is connected to the runner 8 through a telescopic rod 10, and a fixed ring 11 is arranged on the telescopic rod 10; A material inlet and a guide rail 15 are provided, and a paddle 16 is provided on the guide rail 15. The bottom surface of the receiving box 12 is divided into an equal first semicircle and a second semicircle. A plurality...

Embodiment 2

[0034] Based on Embodiment 1, the guide rail 15 is semi-circular. When the pick 16 is positioned at one end of the guide rail 15, the baffle plate 17 is completely positioned on the first semicircle. When the pick 16 is positioned at the other end of the guide rail 15, the pick is 16 is completely located on the second semicircle, and covers all ports of the guide tube 18.

[0035] In this embodiment, the baffle plate 17 is used to seal the port of the guide tube 18, so that the output of the cleaning agent is stopped; when the cleaning agent flows into the brush head 13 from the second semicircle of the brush head 13, because the brush head 13 is constantly rotating , the cleaning agent can evenly cover the entire brush head 13 under the centrifugal action, and the cleaning is more uniform.

Embodiment 3

[0037] Based on Example 1, a sealing cover 14 is provided on the inlet.

[0038] The sealing cover 14 provided in this embodiment seals the material inlet to prevent the cleaning agent from overflowing when the rotating brush 9 rotates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com