Control method of safety valve

A control method and valve technology, applied in the valve operation/release device, sliding valve, valve details, etc., can solve the problems of lack of conditions, inability to meet equipment use conditions, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

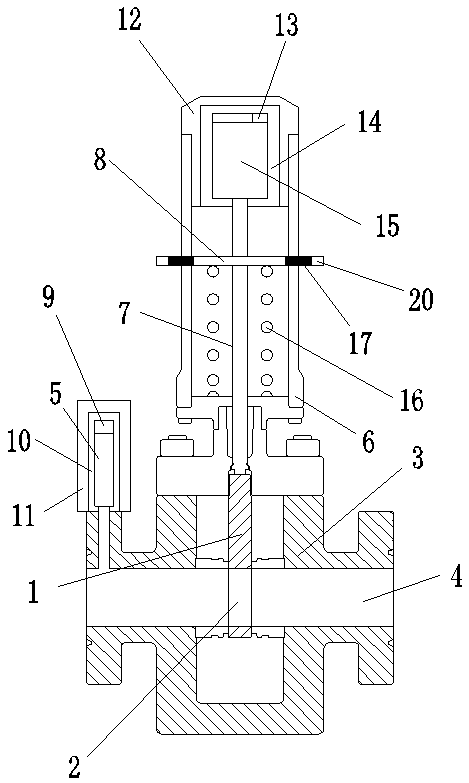

[0031] As a preferred embodiment of the present invention, this embodiment discloses a method for controlling a safety valve, and this embodiment includes:

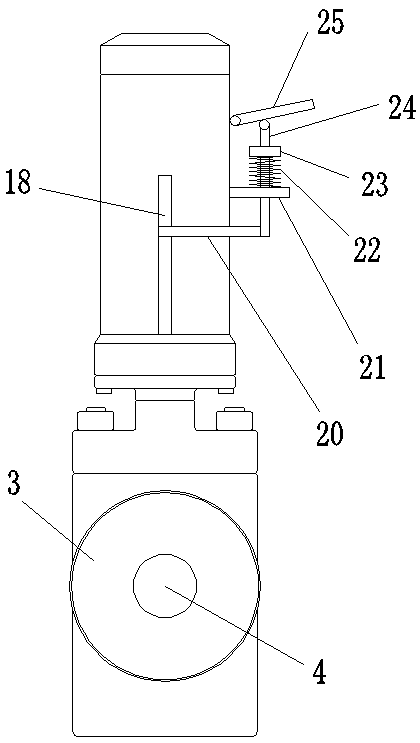

[0032] A method for controlling a safety valve, comprising: a pressure sensor 5 detects the pressure of a pressure pipeline 4 in real time, and when the pressure sensor 5 detects that the pressure of the pressure pipeline 4 is too high, the wireless communication device 1 9 transmits a signal to the wireless communication device 2 13; Cylinder 15 starts after receiving the information, pushes the movable plate 8 downward, and the valve stem 7 under the movable plate 8 drives the gate 1 to move downward to close the valve; when the cylinder 5 fails to close the valve due to failure, The valve can be closed by an emergency shut-off device; the pressure pipeline 4 is faulty removed, and when the valve needs to be opened, the cylinder 5 releases the thrust, and the gate plate 1 moves upward under the elastic force of the sprin...

Embodiment 2

[0043] As a preferred embodiment of the present invention, this embodiment discloses a method for controlling a safety valve, and this embodiment includes:

[0044] A method for controlling a safety valve, comprising: a pressure sensor 5 detects the pressure of a pressure pipeline 4 in real time, and when the pressure sensor 5 detects that the pressure of the pressure pipeline 4 is too high, the wireless communication device 1 9 transmits a signal to the wireless communication device 2 13; Cylinder 15 starts after receiving the information, pushes the movable plate 8 downward, and the valve stem 7 under the movable plate 8 drives the gate 1 to move downward to close the valve; when the cylinder 5 fails to close the valve due to failure, The valve can be closed by an emergency shut-off device; the pressure pipeline 4 is faulty removed, and when the valve needs to be opened, the cylinder 5 releases the thrust, and the gate plate 1 moves upward under the elastic force of the sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com