Straight groove holder circulating type planet pin roller lead screw

A planetary roller and cage technology, applied in the field of transmission, can solve the problems of reducing the nut moving speed, no axial relative motion, low precision, etc., to increase the processing cost and processing difficulty, reduce the moving speed, and meet the needs of small lead effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

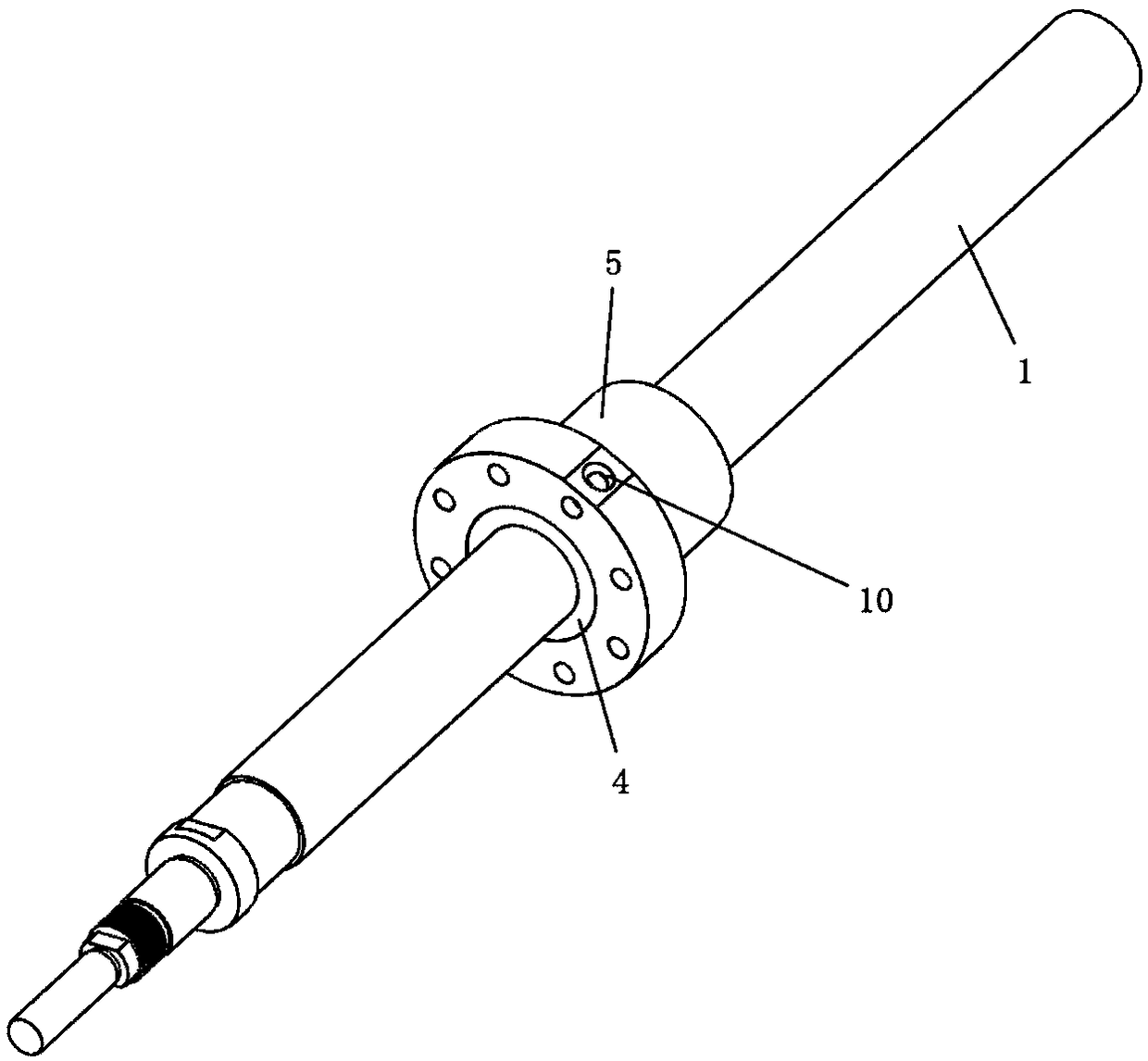

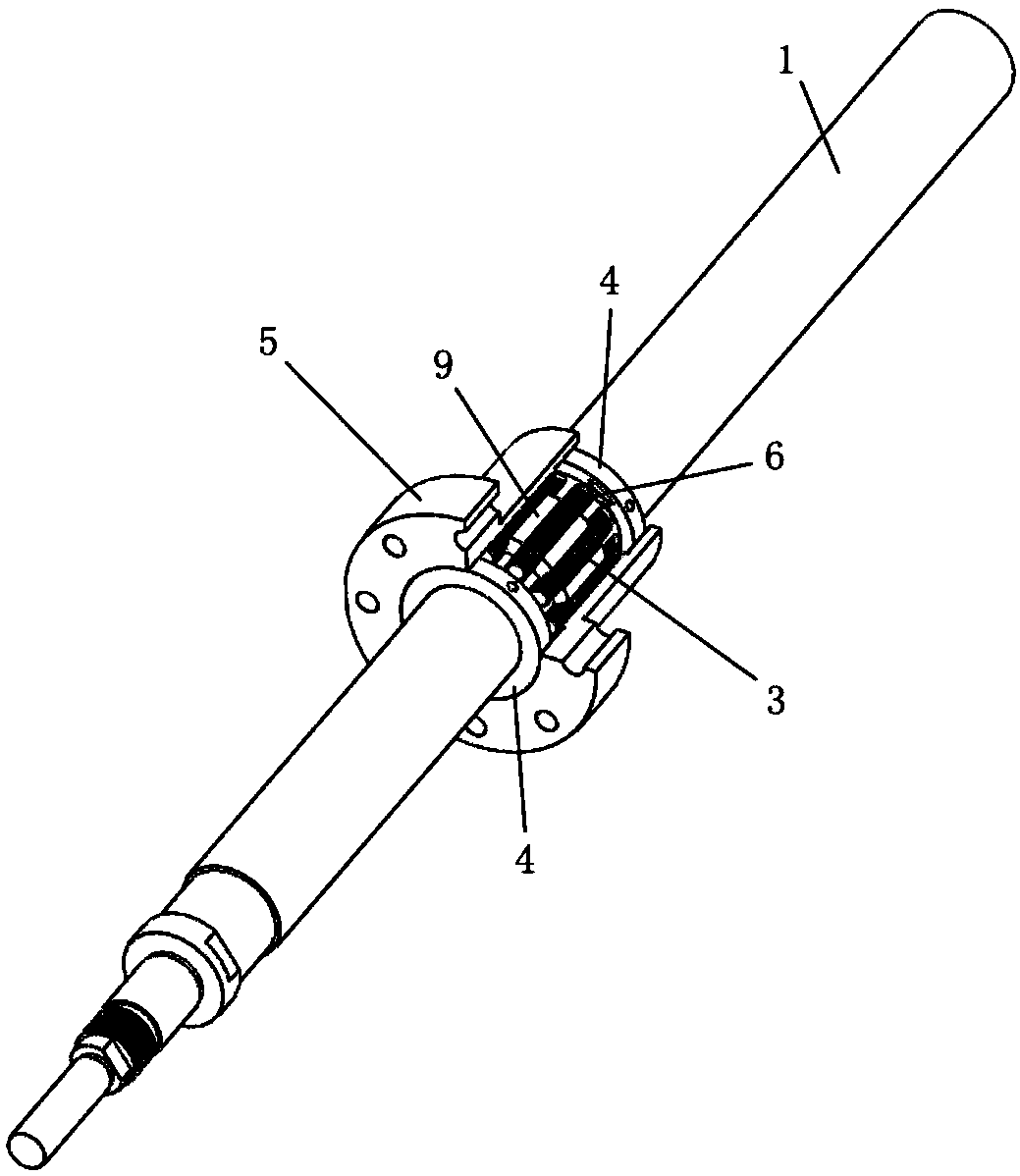

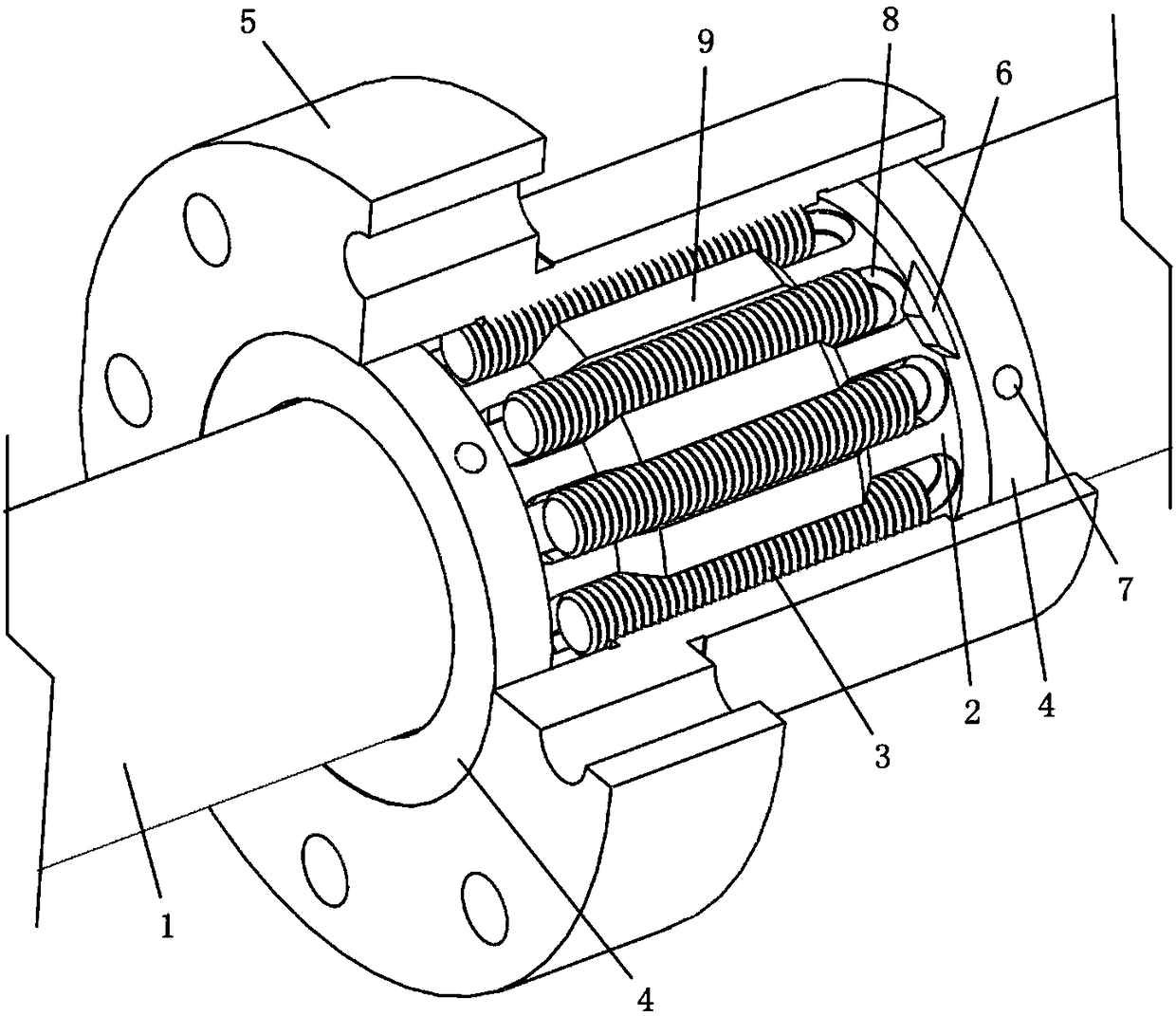

[0021] reference Figure 1 to Figure 5 , A straight groove cage circulating planetary roller screw, comprising a main screw 1, a cage 2, a roller 3, and a nut 5. The main screw 1 and the inner wall of the nut 5 are both provided with threads, so The roller 3 is located in the linear through groove 8 of the cage 2, the cage 2 and the nut 5 are arranged coaxially with the main screw 1, and the rollers 3 are arranged in a planetary circumferential array relative to the main screw 1. The length of the straight groove 8 of the cage 2 is greater than the axial length of the roller 3, the roller 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com