Rectangular pipe jacking machine excavation face blind area crushing device and method

A technology of a crushing device and a crushing method, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of increasing jacking resistance and the inability to cut pipes in jacking, so as to improve cutting efficiency, and the combined structure is simple and feasible, which is conducive to smooth operation. The effect of exclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Installation of the crushing device in the blind area of the excavation face of the rectangular pipe jacking machine.

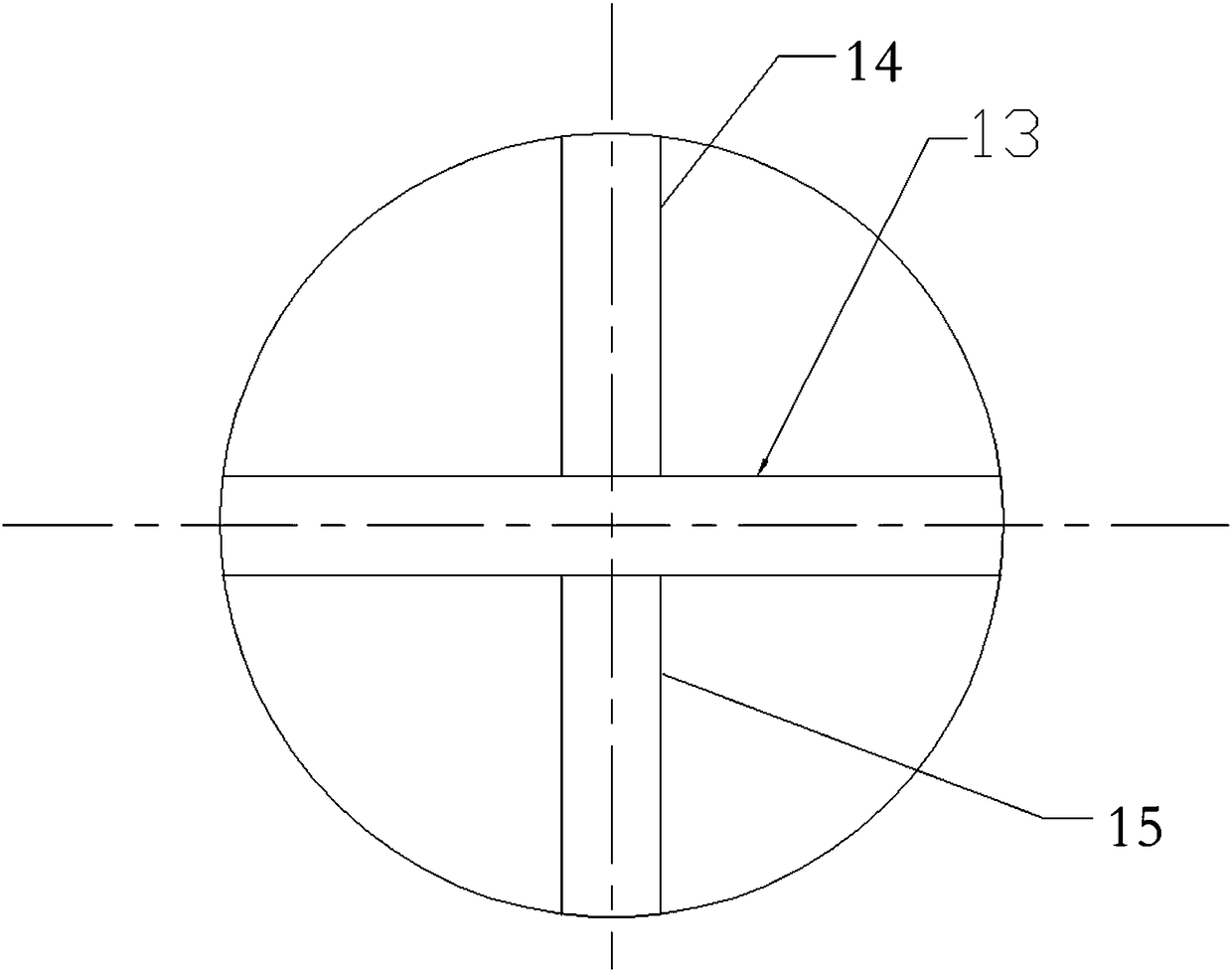

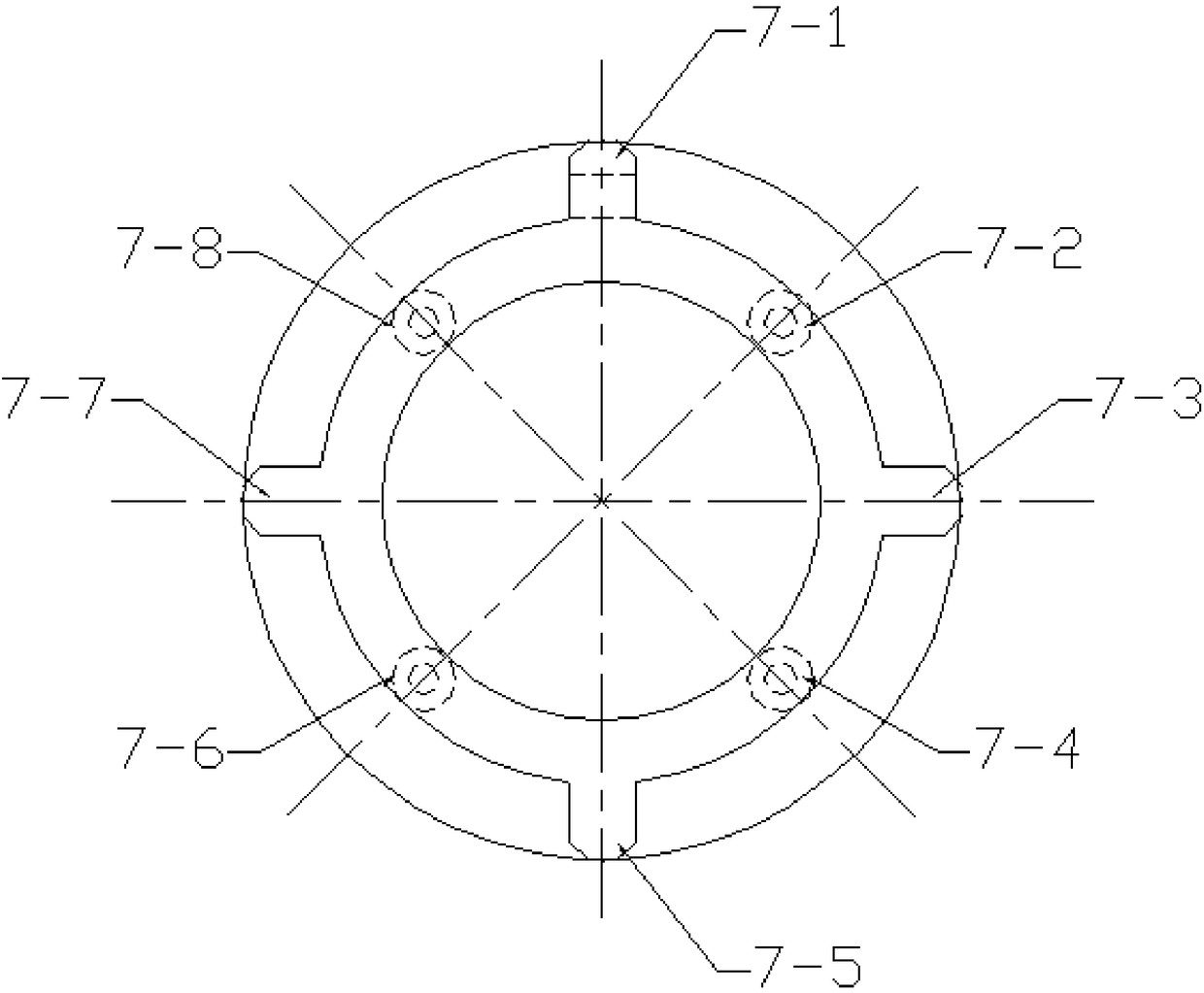

[0026] 1. See figure 1 , according to the size of the blind area, select a certain size of the cylinder, and weld the cross-cone soil breaking device and the front end of the piston rod of the cylinder together, and the stroke of the cylinder maintains zero displacement. One to two cutting devices are recommended for each blind zone;

[0027] 2. According to the size of the oil cylinder, process and assemble the high-pressure water jet device that matches it;

[0028] 3. Cut out round holes suitable for cylinders, bolts and high-pressure water channels in the blind area of the excavation panel of the rectangular pipe jacking machine;

[0029] 4. Install the oil cylinder and the cross-cone soil breaking device on the panel of the pipe jacking machine and fix them with bolts. It should be noted that the high-pressure water channel is...

example 2

[0031] Example 2: The method of using the crushing device in the blind area of the excavation face of the rectangular pipe jacking machine.

[0032] 1. When drilling into soft rock or reinforced area and finding that the jacking force is too large, open the oil cylinder in time, refuel from the oil inlet, and at the same time use high-pressure jet device to inject water into the high-pressure water channel;

[0033] 2. Stop refueling when the oil cylinder reaches its full stroke, and keep injecting high-pressure water continuously;

[0034] 3. When the jacking force decreases and remains relatively stable, the oil cylinder can be recovered and the injection of high-pressure water will be stopped at the same time;

[0035] 4. When the jacking force does not decrease or the decrease is not obvious, keep injecting high-pressure water, retract the oil cylinder to the initial position of the oil cylinder, it is recommended not to reach the zero stroke, then refuel at the oil inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com