Concrete scabbler head and concrete scabbler using same

A technology of chisel machine and machine head, which is applied in the field of chisel machine and chisel machine head. It can solve the problems of unfavorable high-efficiency and high-quality completion of the project, uneven chisel area, inconsistent impact depth, etc., and achieve fast and effective treatment. , Uniform chisel and consistent impact depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

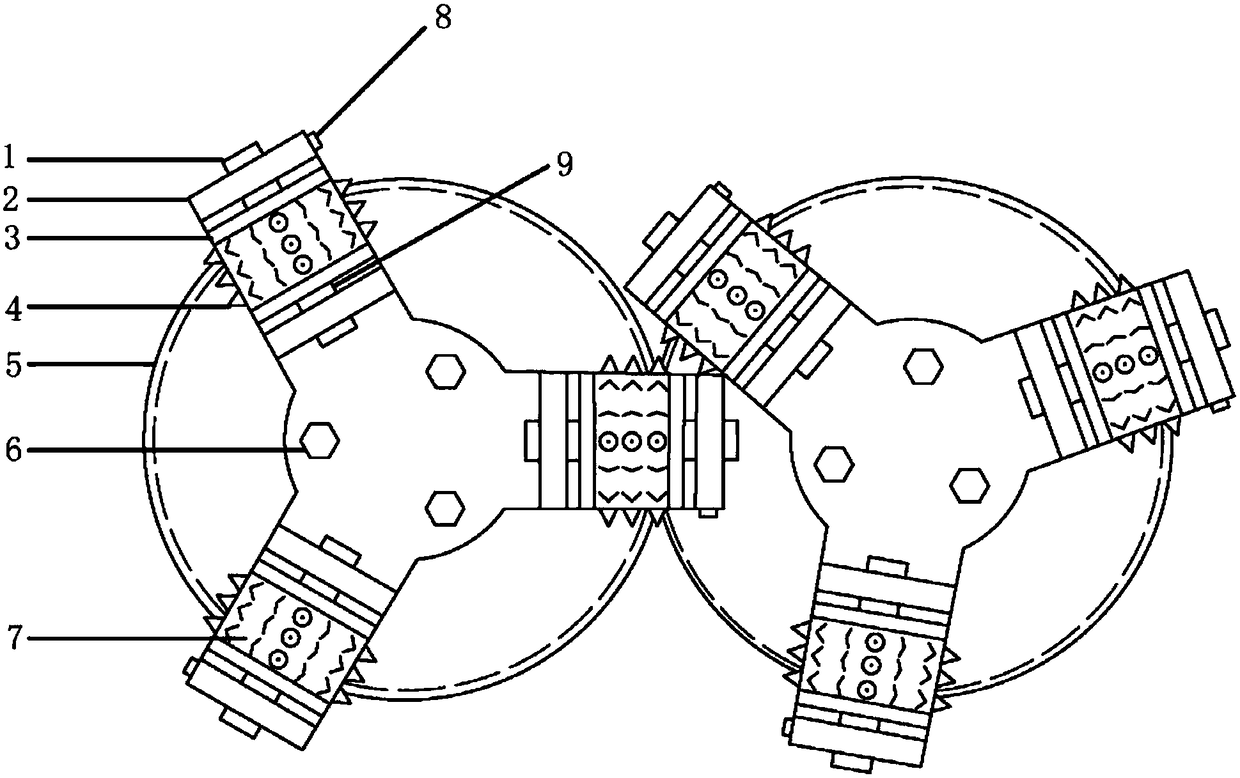

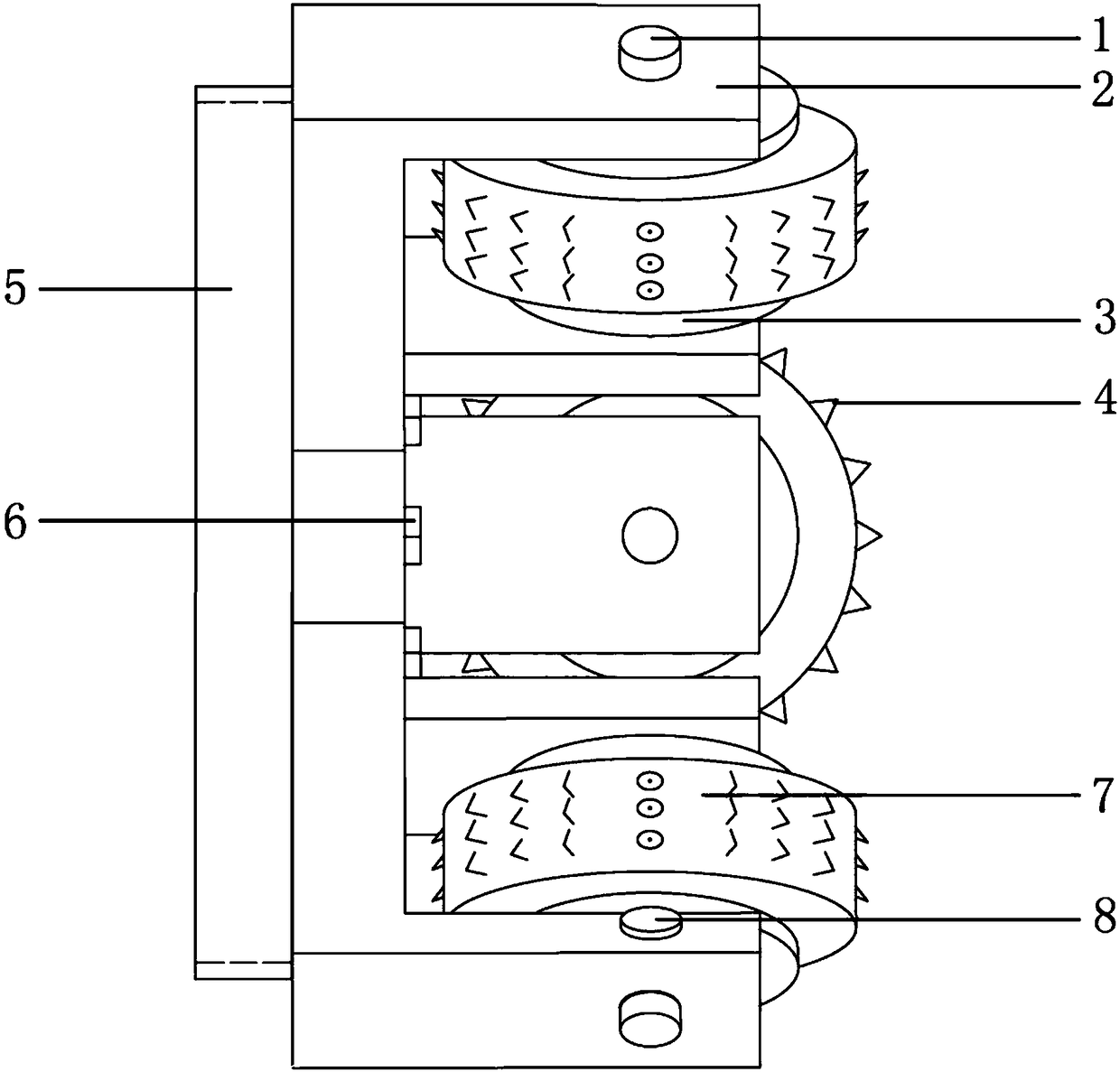

[0018] like figure 1 Shown: a chisel machine head, including a roller frame 2, a roller 7 mounted on the roller frame 2, a roller shaft 9 passing through the roller 7 to be fixed on the roller frame, a bearing, a dustproof bearing cover 3, With the fixed gear shaft 5 of the roller frame 2, the described roller frame 2 rotates together with the gear shaft 5, and the described roller 7 rotates around the roller shaft 9, and the roller 7 is provided with a protrusion 4. The roller frame 2 is in the shape of a "Y", each fork is a branch, the interval angle of each branch is the same, and the length is the same, and each branch is provided with a roller 7. There is an angle of 120 degrees between every two roller frames 2 , and the support bar on which the roller frames 2 are installed with the rollers 7 is perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com