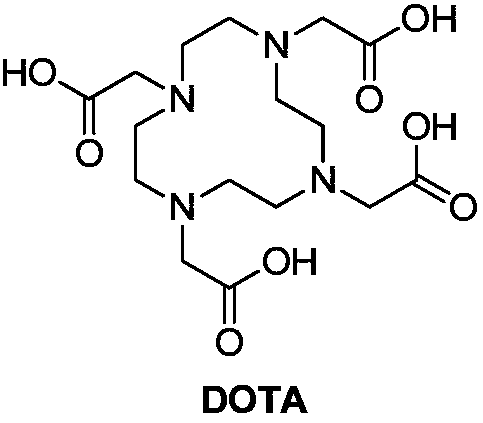

Preparation method of 1,4,7,10-tetraazacyclododecane-1,4,7-10-tetraacetic acid

一种酸性、烷基的技术,应用在有机化学等方向,能够解决耗能耗时长、不易操作、温度要求较高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] At 0-10°C, add cyclen (17.27g, 100mmol), lithium hydroxide monohydrate (36.92g, 880mmol), and water (80mL) into a three-necked flask (1000mL). A solution of bromoacetic acid (61.14 g, 440 mmol) in water (30 mL) was added at 5-15 °C. Heat to 20-30° C. for 24 hours, and TLC detects that there is no remaining cyclen of the raw material. Add 36% hydrochloric acid (44.6g, 440mmol) to the system, add ethanol (600mL), precipitate a solid, filter, recrystallize and purify the obtained solid with ethanol / water (volume ratio: 3:1), and dry at 60°C to obtain DOTA.

[0065] Yield: 85.5%, HPLC: 99.7%, residue on ignition: 0.05%, moisture: 7.80%.

Embodiment 2

[0067] At 0-10°C, add cyclen (17.27g, 100mmol), lithium hydroxide monohydrate (36.92g, 880mmol), and water (80mL) into a three-necked flask (1000mL). A solution of bromoacetic acid (61.14 g, 440 mmol) in water (30 mL) was added at 5-15 °C. Incubate at 5-15°C for 24 hours, and TLC detects that there is no remaining cyclen of raw materials. Add 36% hydrochloric acid (44.6g, 440mmol) to the system, add ethanol (600mL), precipitate a solid, filter, recrystallize and purify the obtained solid with ethanol / water (volume ratio: 3:1), and dry at 60°C to obtain DOTA.

[0068] Yield: 78.0%, HPLC: 99.9%, residue on ignition: 0.05%, moisture: 6.25%.

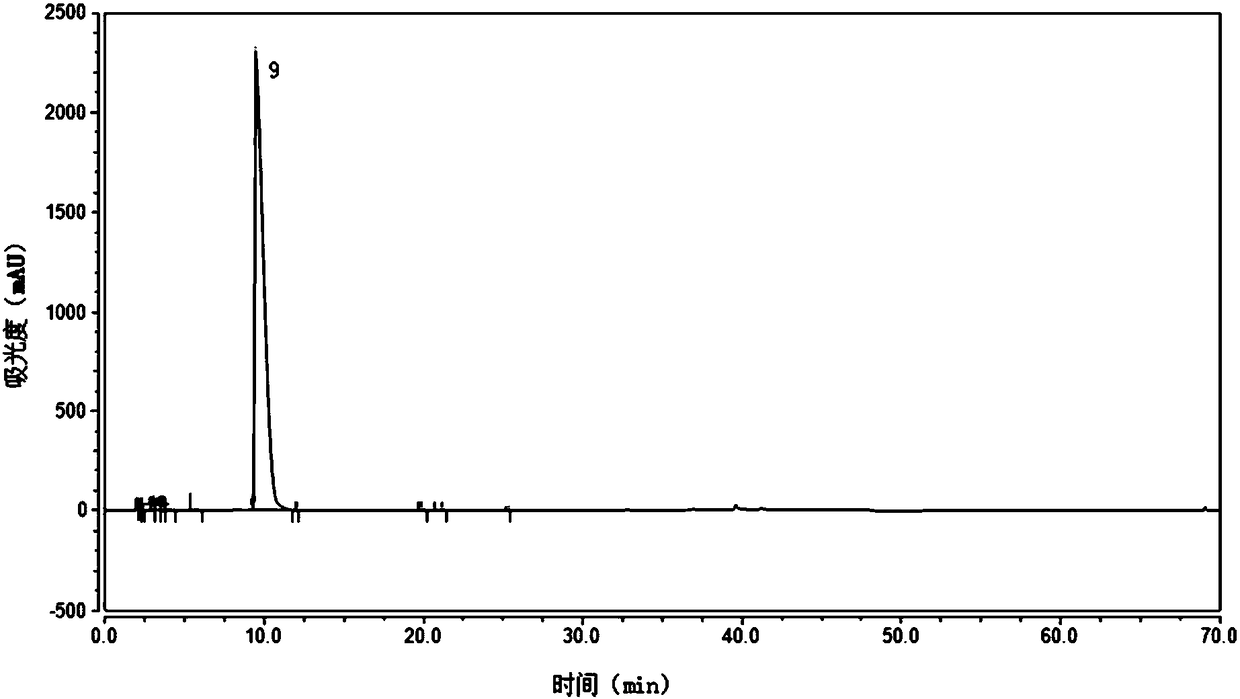

[0069] Wherein, the HPLC purity data of product sees the table below (see figure 1 ), its retention time is 9.447min.

[0070] Table 1

[0071]

[0072]

Embodiment 3

[0074] At 0-10°C, add cyclen (17.27g, 100mmol), lithium hydroxide monohydrate (36.92g, 880mmol), and water (80mL) into a three-necked flask (1000mL). A solution of bromoacetic acid (61.14 g, 440 mmol) in water (30 mL) was added at 5-15 °C. Heat to 35-45° C. for 24 hours, and TLC detects that there is no remaining cyclen of the raw material. Add 36% hydrochloric acid (44.6g, 440mmol) to the system, add ethanol (600mL), precipitate a solid, filter, recrystallize and purify the obtained solid with ethanol / water (volume ratio: 3:1), and dry at 60°C to obtain DOTA.

[0075] Yield: 82.3%, HPLC: 99.6%, residue on ignition: 0.06%, moisture: 5.60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com