Waste beer bottle ceramic color glaze production and application method

A production method and technology for beer bottles, applied in the field of materials, can solve the problems of high cost of raw materials, difficult comprehensive treatment of waste beer bottles, etc., and achieve the effects of high utilization rate, major social benefits and environmental protection significance, and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

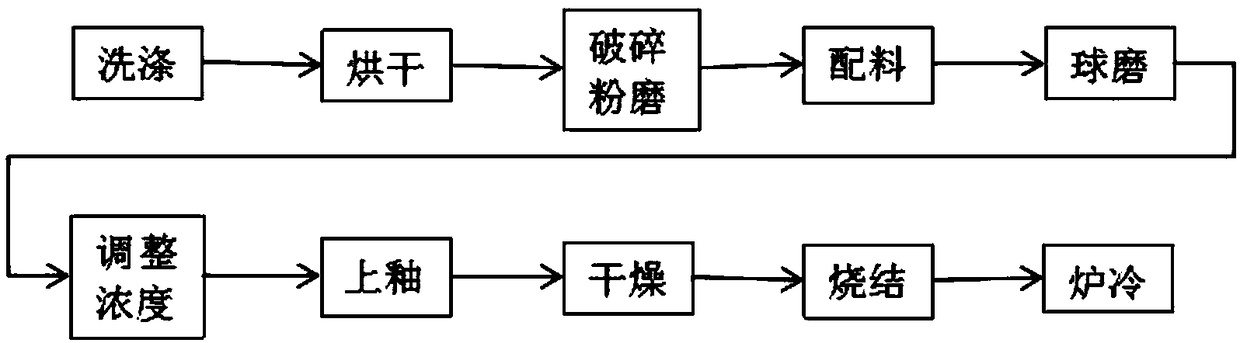

Method used

Image

Examples

Embodiment 1

[0026] The mass percent of the raw material formula of this example is: waste beer bottle 30%, kaolin 4%, quartz 17%, albite feldspar 27%, potassium feldspar 3%, limestone 3%, dolomite 5%, zinc oxide 8%, carbonic acid Barium 3%. After the raw materials are mixed according to the proportion, they are ball-milled in a planetary ball mill for 2 hours by wet method, material: ball: water = 1:1.5:0.5. Filter the ground slurry and adjust the concentration to glaze: water = 0.5:1. Glaze the upper surface of the green body after bisque firing, the thickness of the glaze layer is about 0.3 mm, and dry at room temperature for 4 hours. The dried green body is fired in a resistance furnace at high temperature, the heating rate is 7.2°C / min, the calcination temperature is 1100°C, the holding time is 20min, and it is cooled with the furnace. The brightness of the glaze is not high, showing a matte effect, no bubbles and other defects, the base glaze is well bonded, and the finished produc...

Embodiment 2

[0028] The mass percent of the raw material formula of this example is: waste beer bottle 50%, kaolin 3%, quartz 12%, albite 19%, potassium feldspar 2%, limestone 3%, dolomite 3%, zinc oxide 6%, carbonic acid Barium 2%. After the raw materials are mixed according to the ratio, they are wet-milled in a planetary ball mill for 3 hours, material: ball: water = 1:1.5:0.5. Filter the ground slurry and adjust the concentration to glaze: water = 0.6:1. Glaze the surface of the green body after bisque firing, the thickness of the glaze layer is about 0.4mm, and dry at room temperature for 5 hours. The dried green body was fired at high temperature in a resistance furnace, the heating rate was 7.2°C / min, the calcination temperature was 1100°C, the holding time was 30min, and it was cooled with the furnace. The glaze surface is bright, showing a mirror effect, without bubbles, pits and other defects, the base glaze is well bonded, and the finished product is light brown cracked glaze....

Embodiment 3

[0030] The mass percent of the raw material formula of this example is: waste beer bottle 50%, kaolin 3%, quartz 12%, albite 19%, potassium feldspar 2%, limestone 3%, dolomite 3%, zinc oxide 6%, carbonic acid Barium 2%. After the raw materials are mixed according to the ratio, they are wet-milled in a planetary ball mill for 3 hours, material: ball: water = 1:1.5:0.5. Filter the ground slurry and adjust the concentration to glaze: water = 0.7:1. Glaze the surface of the green body after bisque firing, the thickness of the glaze layer is about 0.5mm, and dry at room temperature for 6 hours. The dried green body is fired in a resistance furnace at high temperature, the heating rate is 7.2°C / min, the calcination temperature is 1300°C, the holding time is 20min, and it is cooled with the furnace. The gloss of the glaze surface is good, without defects such as cracks and bubbles, and the base glaze is well combined to form a transparent glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com