Oil press with functions of buffering, noise reduction and convenient mold mounting and dismounting

A technology for hydraulic presses and molds, applied in the field of hydraulic presses, can solve problems such as affecting the guidance of the middle beam, low reliability, and no buffering and noise reduction function, so as to achieve buffering and noise reduction for loading and unloading molds, preventing damage to guide posts, and facilitating loading and unloading of molds. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is further described;

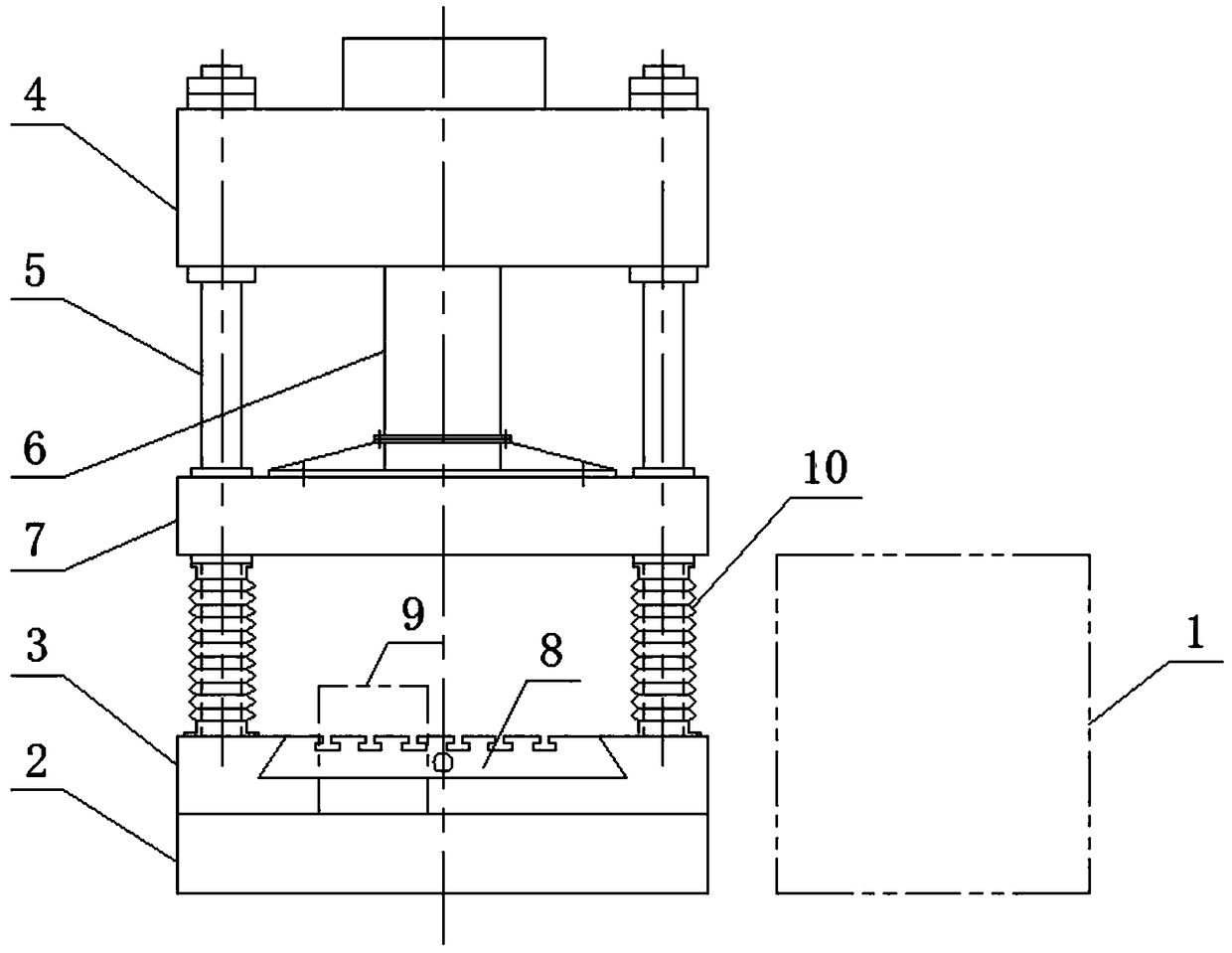

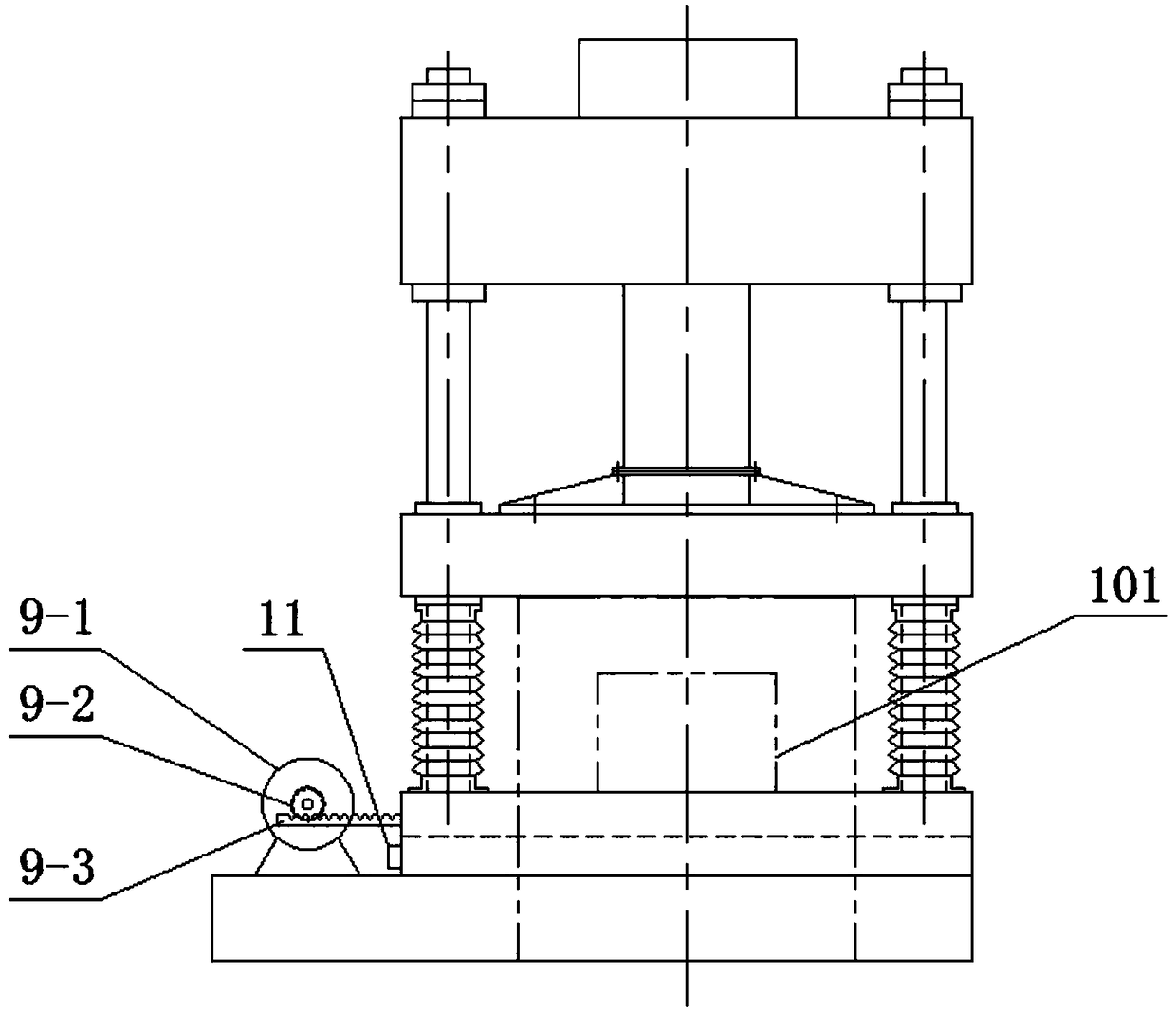

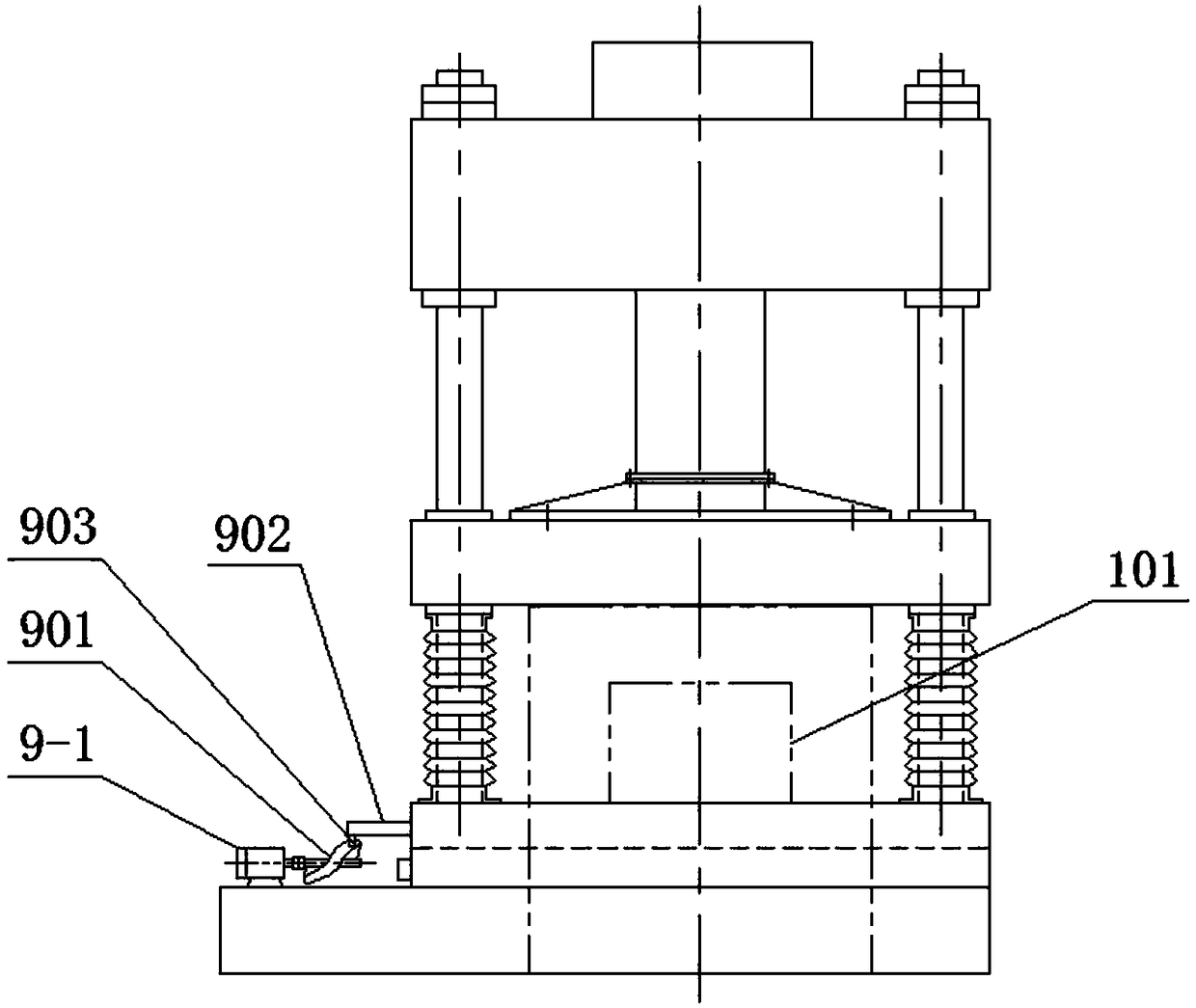

[0020] exist figure 1 , figure 2 Middle: the first embodiment:

[0021] A hydraulic press with the functions of buffering and noise reduction and convenient mold loading and unloading, including a hydraulic control structure 1, a base 2, a workbench 3 arranged on the base 2, an upper beam 4, and a guide connected between the workbench 3 and the upper beam 4 column 5, and the middle beam 7 connected to the upper beam 4 through the oil cylinder 6 and connected to the guide column 5; the workbench 3 is a split structure, including a fixed part connected to the base 2 and the guide column 5 , and the sliding block 8 connected to the fixed part; the base 2 is also provided with a drive structure 9 connected to the sliding block 8 for driving the sliding block 8 to move back and forth along the linear direction on the fixed part ; The guide post 5 is covered with a rubber buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com