Novel monomer aluminum air battery

An aluminum-air battery, a single technology, applied in hybrid batteries, circuits, electrical components, etc., can solve the problems of complex processing technology, increased size of the stack, too many welding points, etc., to achieve simple operation and processing technology, prevent The effect of short-circuiting the positive contact and reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

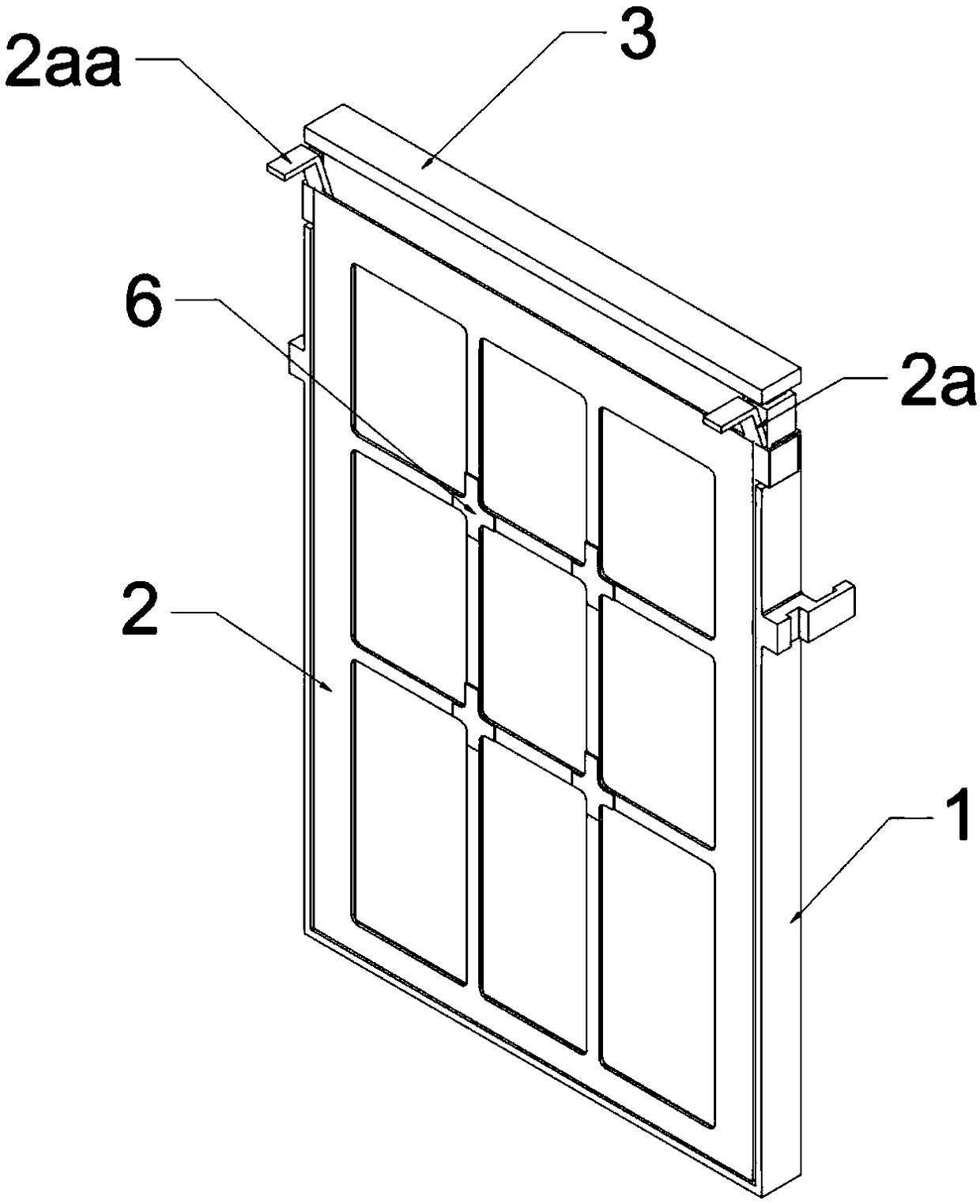

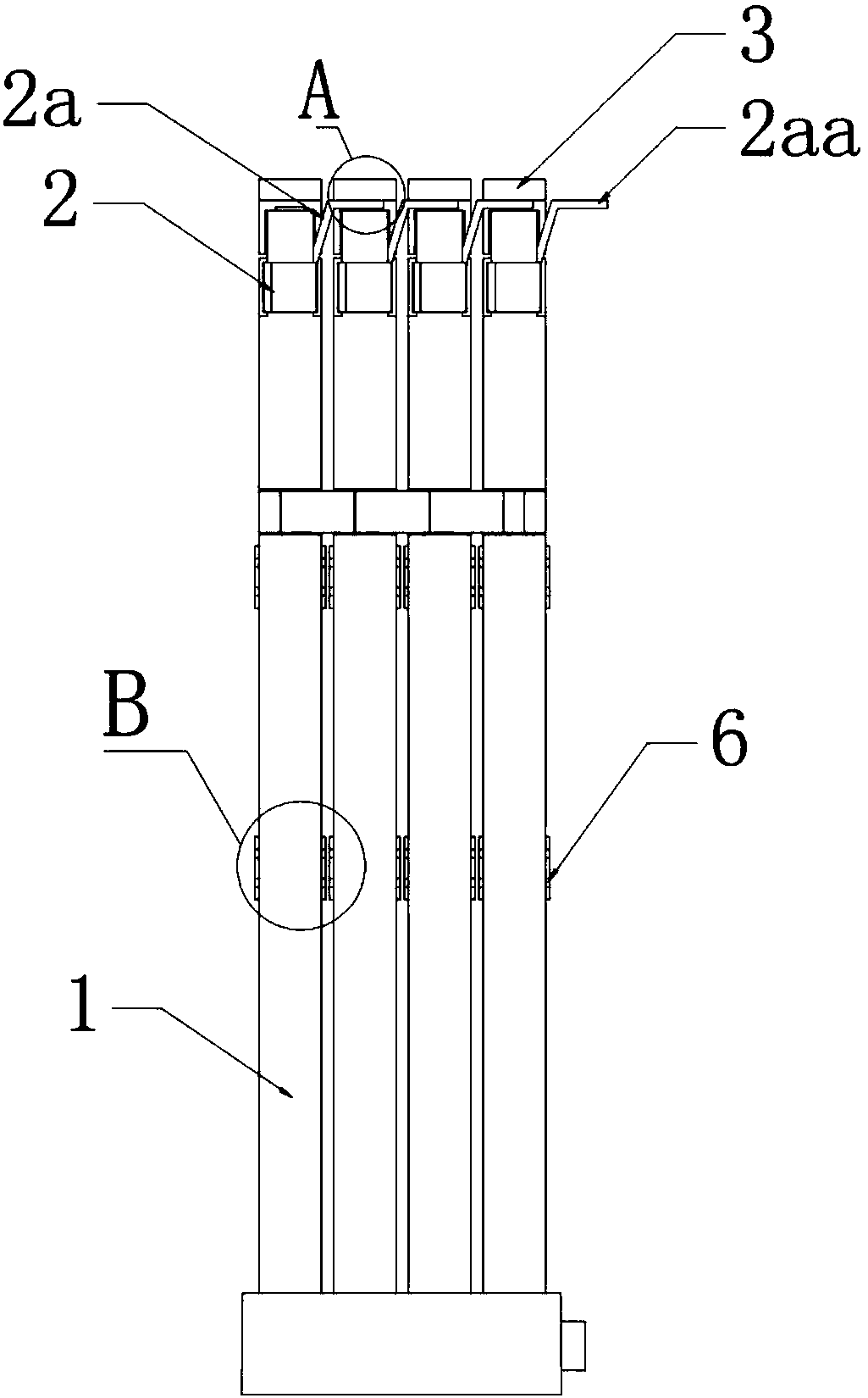

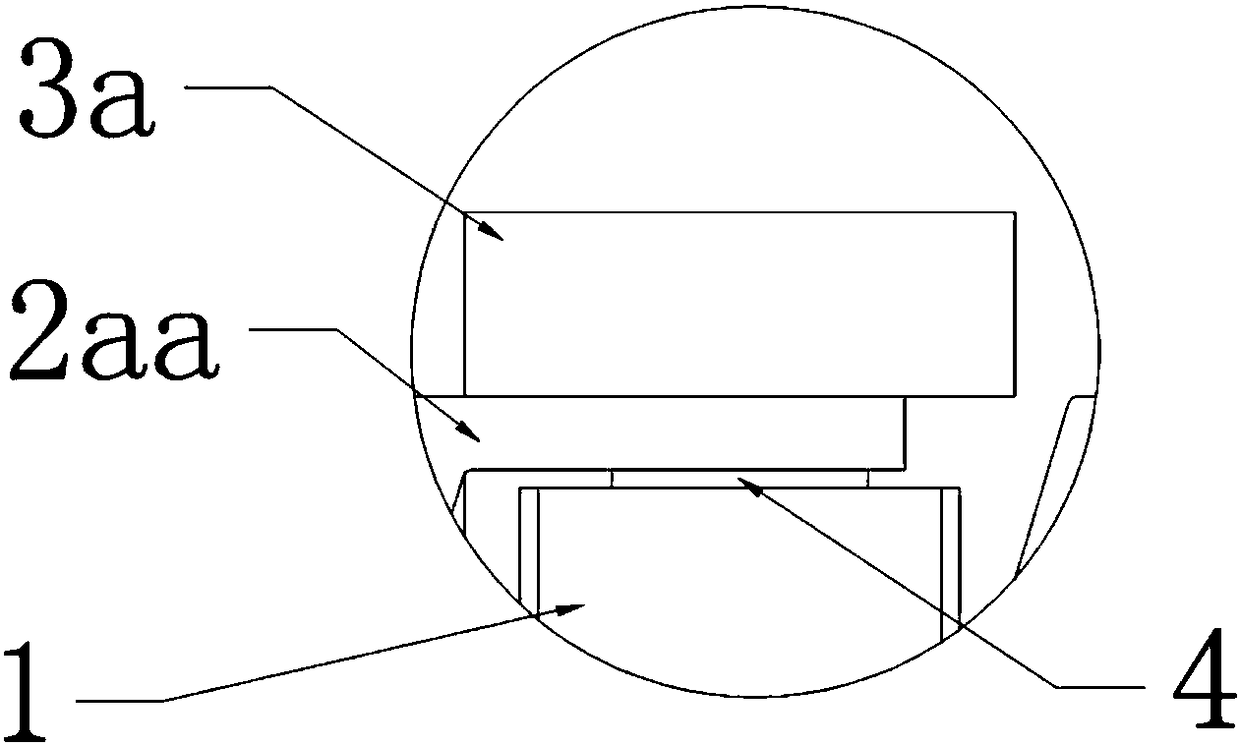

[0022] like Figure 1 to Figure 4 A new single aluminum-air battery shown has a battery liquid cavity 1, an aluminum plate is inserted in the battery liquid cavity 1, a negative plate 3 is arranged on the aluminum plate, and the negative plate 3 is integrally formed with the aluminum plate . A liquid tank 3b is respectively arranged on the front and rear sides of the negative electrode plate 3 , and the liquid tank 3b is arranged throughout along the left and right directions. A positive plate 2 is arranged on the battery liquid cavity 1 . The positive plate 2 covers the front and rear surfaces of the battery liquid cavity 1, and a plurality of bosses 6 made of insulating material are arranged on the front and back surfaces of the positive plate 2. Preferably, the bosses 6 are in the shape of a "cross". Each positive plate 2 is connected with a conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com