Spiral evaporator and running method thereof

A spiral evaporator and spiral technology, applied in the field of machinery, can solve problems such as uneven condensation and freezing, poor cooling effect, and low usage rate of refrigerant dosage, so as to achieve the effect of improving the effect and uniformity, and improving the utilization rate of coolant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

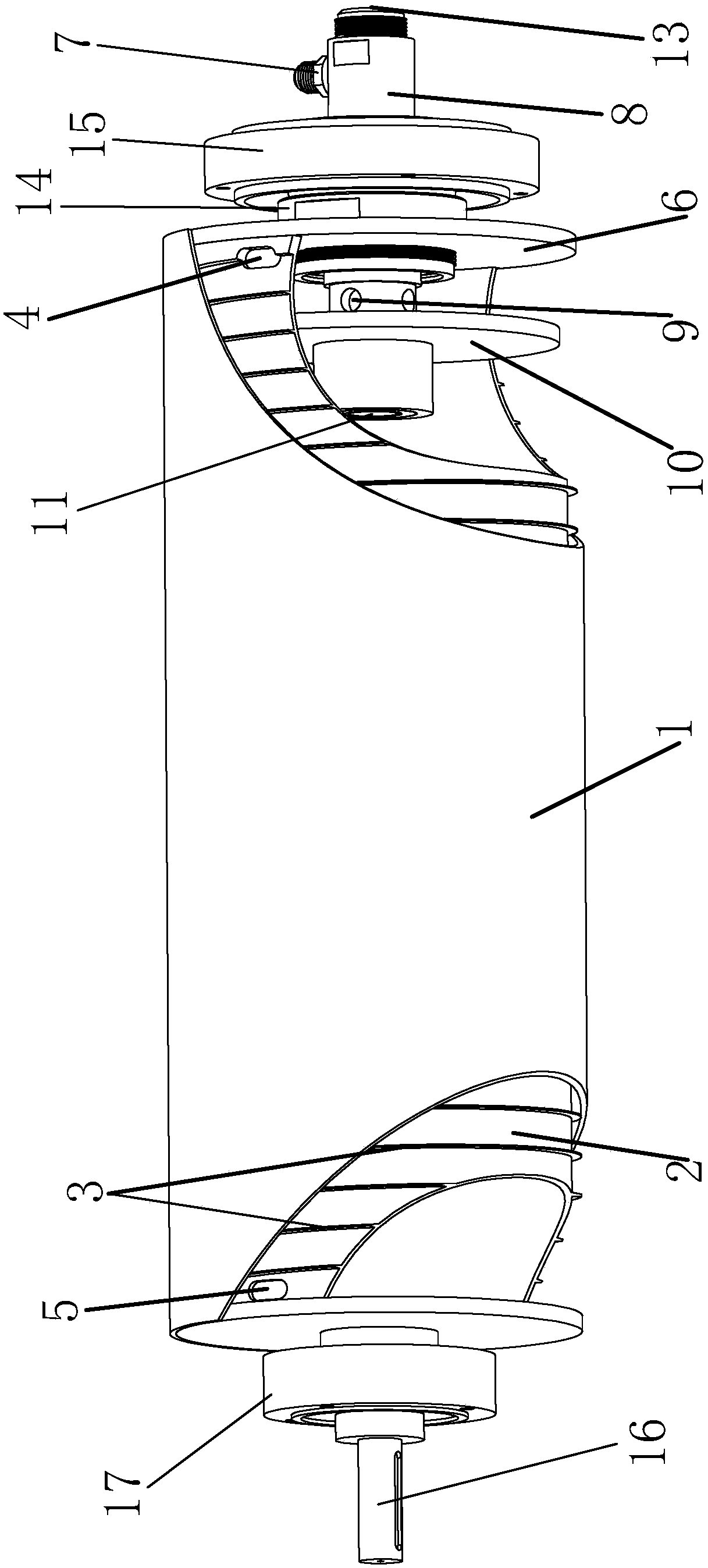

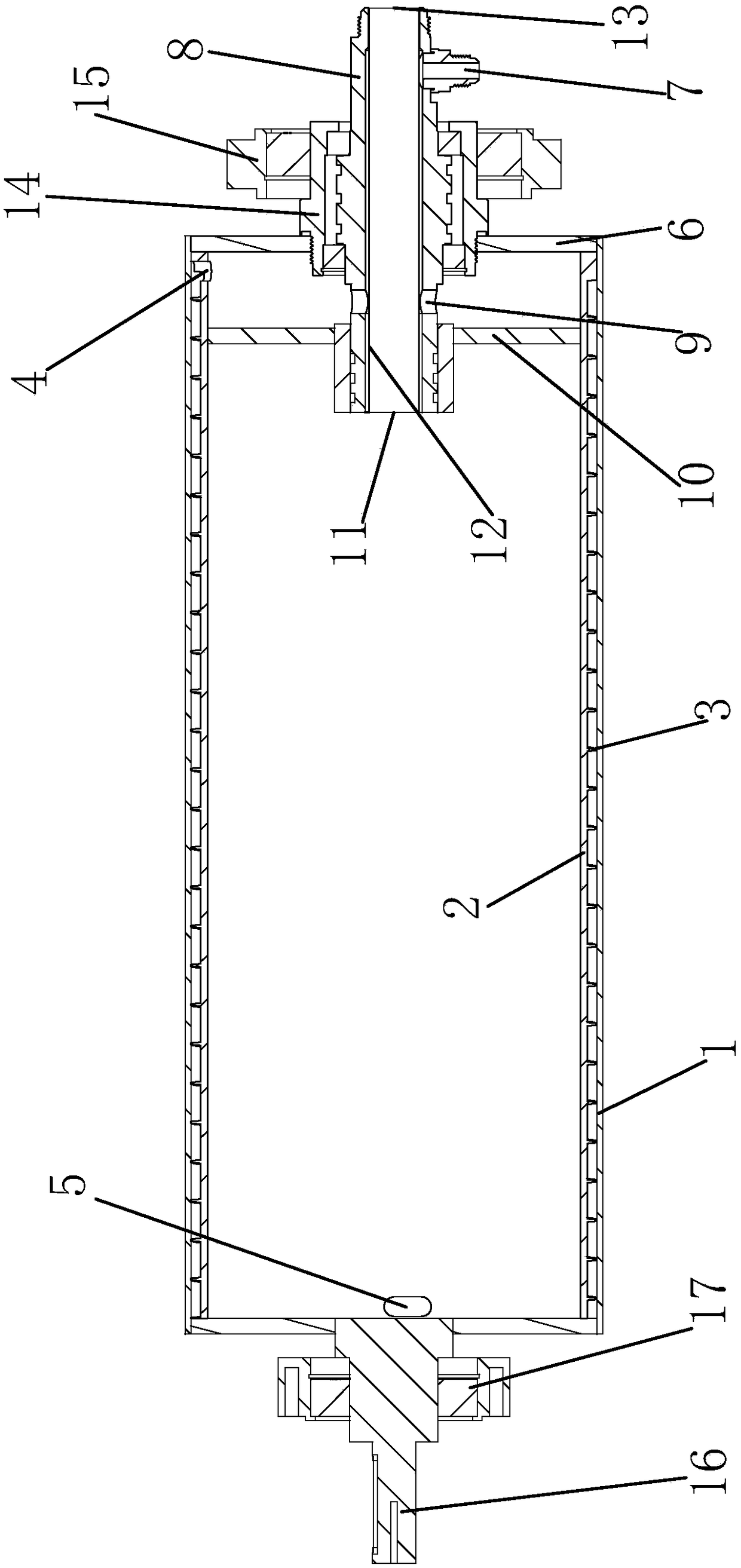

[0021] Such as figure 1 and figure 2 As shown, the spiral evaporator includes a drum shell. One end of the drum shell is a closed end, and the other end is provided with a baffle 6. The center of the baffle 6 has an opening. The drum shell includes a cylindrical shell 1 and a spiral inner shell. 2. A spiral wall 3 is provided on the outer wall of the spiral inner shell 2, and the bottom of the spiral wall 3 is fixedly connected to the spiral inner shell 2. The top of the spiral wall 3 forms a close connection with the inner wall surface of the cylindrical shell 1. Through The spiral inner shell 2, the spiral wall 3 and the cylindrical shell 1 are combined to form a spiral flow channel extending in the spiral direction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com