Single-drive control invisible connecting device

A connecting device and a single-drive technology, which is applied in the direction of connecting members, specially improved connectors and screws for tensile loads, can solve the problems of affecting appearance and cumbersome operation, and achieve the effect of easy disassembly and assembly and guarantee of perfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

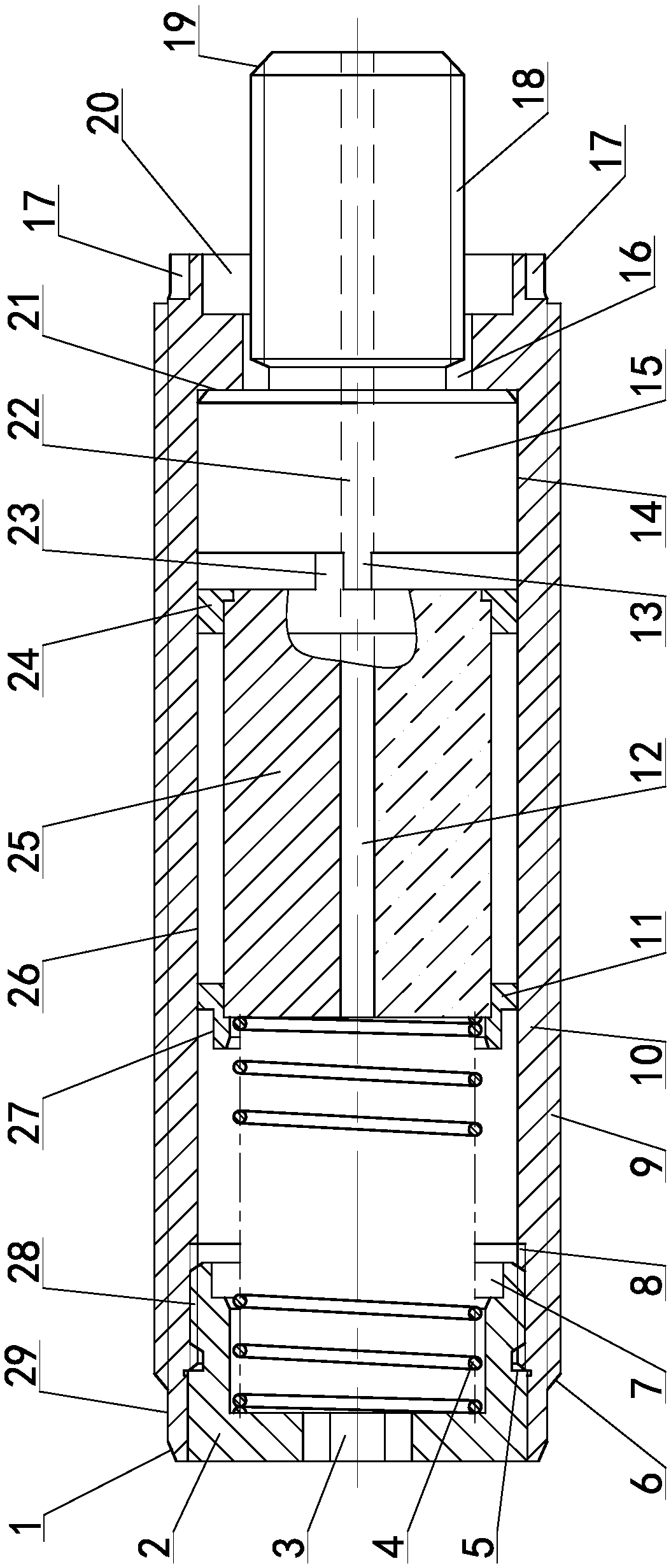

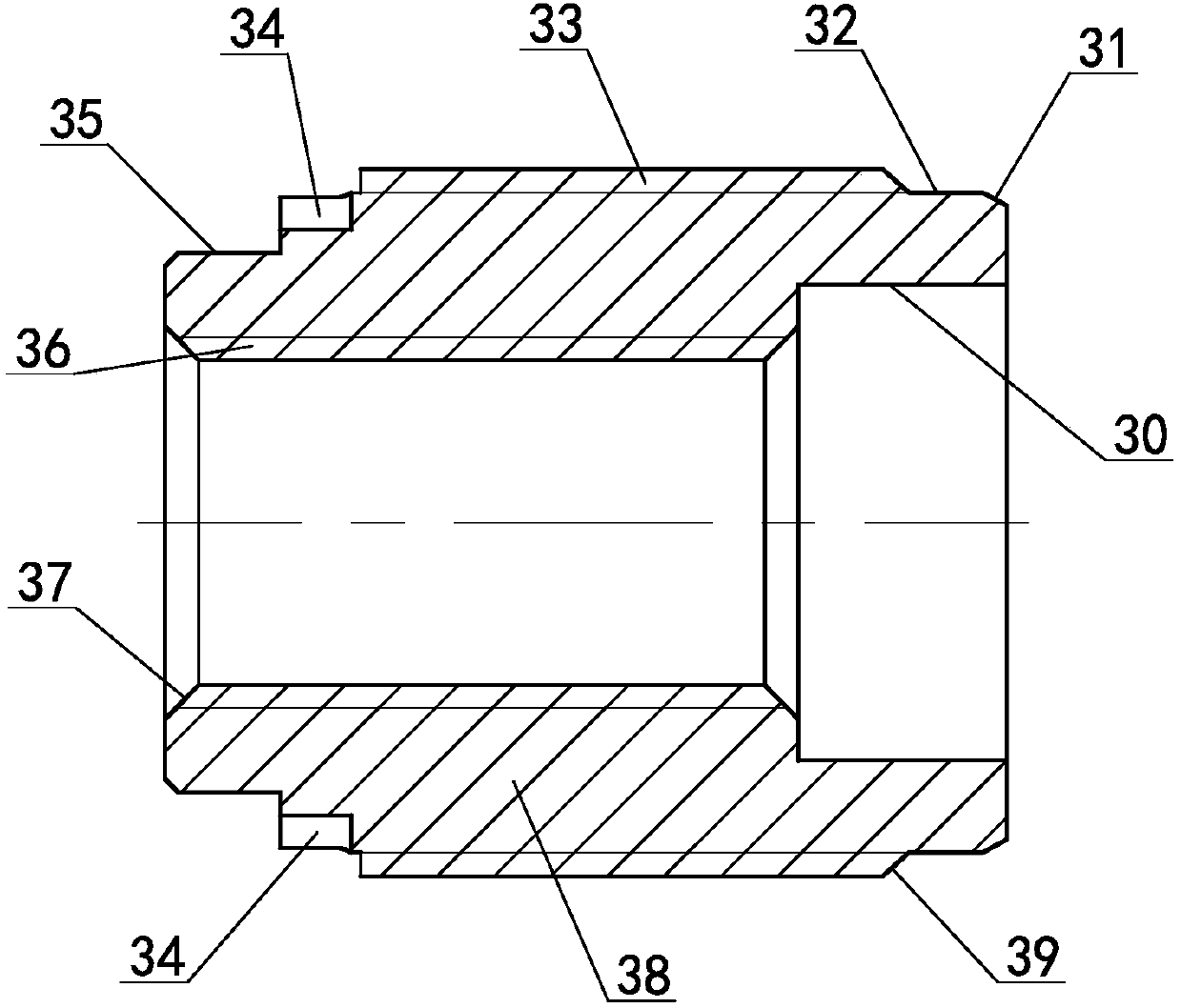

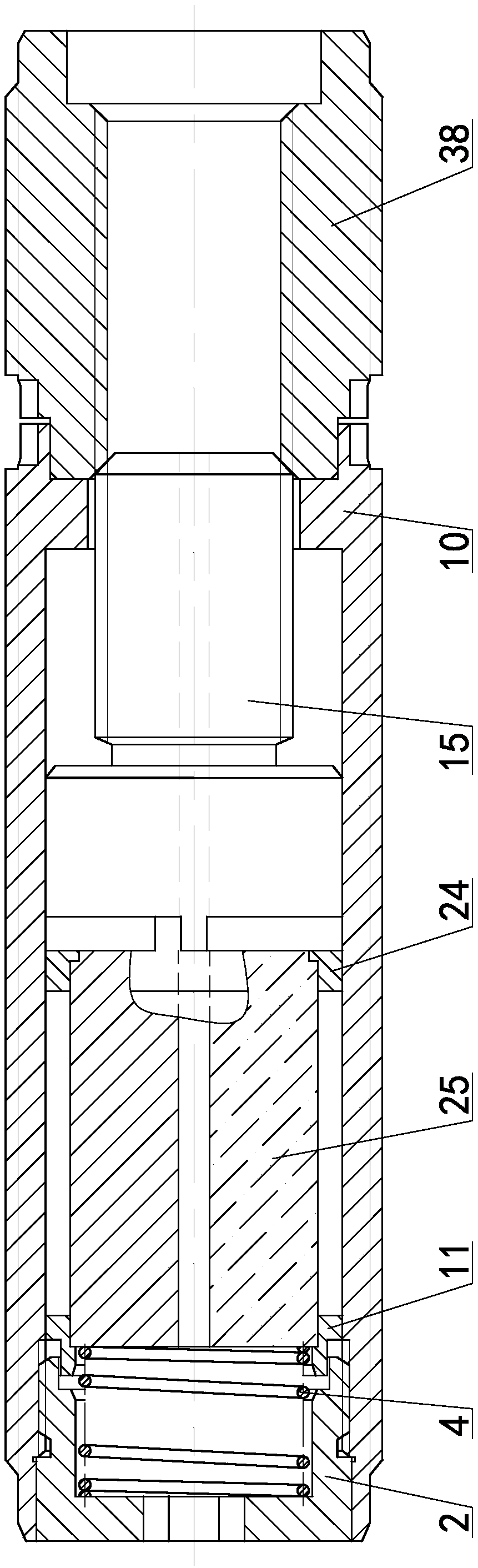

[0026] see Figure 1 ~ Figure 4 The single-drive control invisible connection device includes the first guide cone surface 1, the screw plug 2, the screw plug inner hexagon 3, the return spring 4, the screw plug limit end surface 5, the second guide cone surface 6, and the screw plug inner cavity hole 7 , main drive internal thread 8, main drive external thread 9, main drive body 10, drive magnet rear end bracket 11, first through hole 12, driven convex pin 13, bolt body matching outer circle 14, connecting bolt body 15, main Drive body connection channel 16, main drive body installation groove 17, plug external thread 18, plug body guide cone surface 19, main drive body connection cavity 20, main drive inner ring end face 21, second throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com