multi-stage turbine rotor

A turbine rotor and disc technology, applied in the field of multi-stage turbine rotor components, can solve problems such as disc failure, disc damage, and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

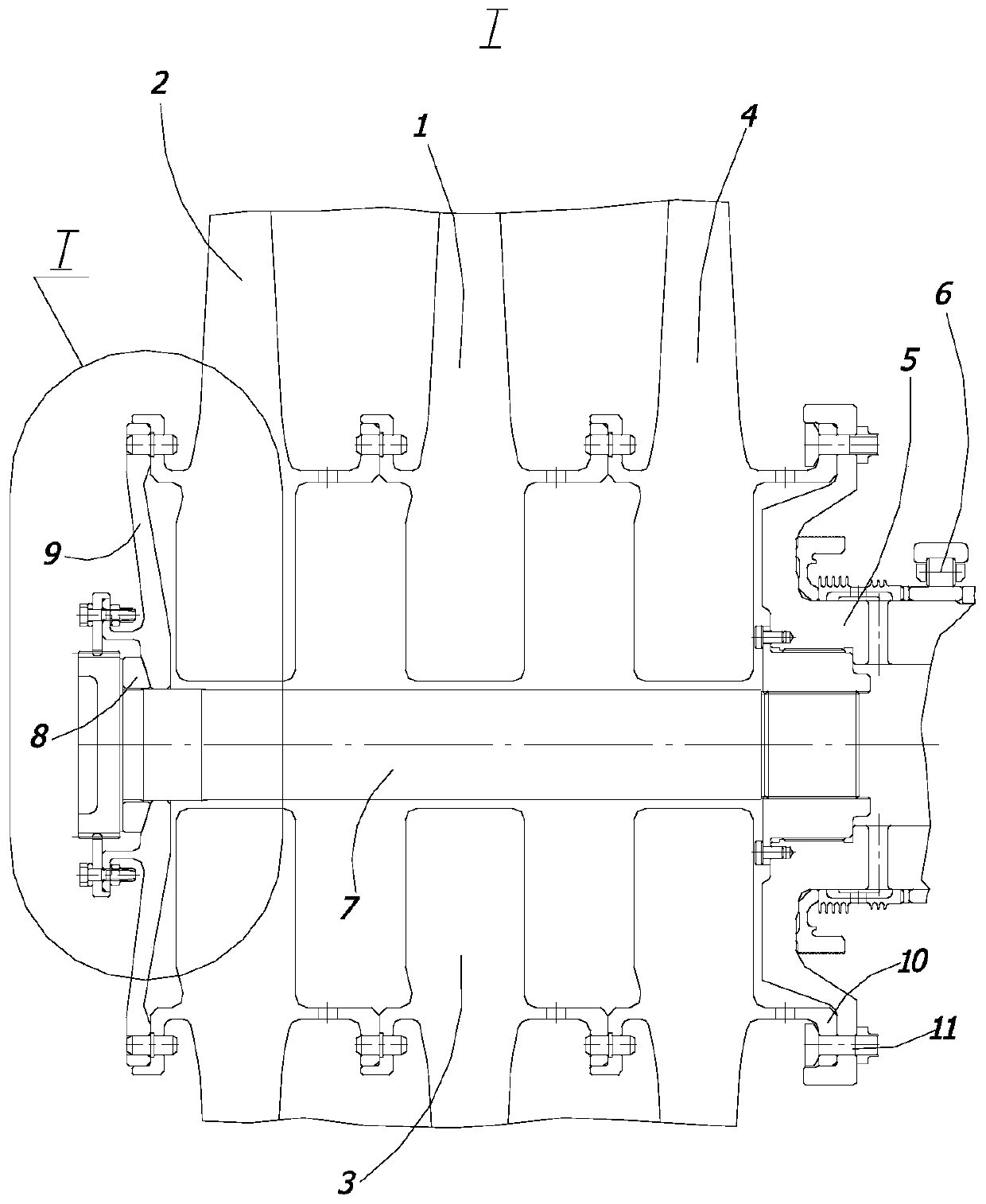

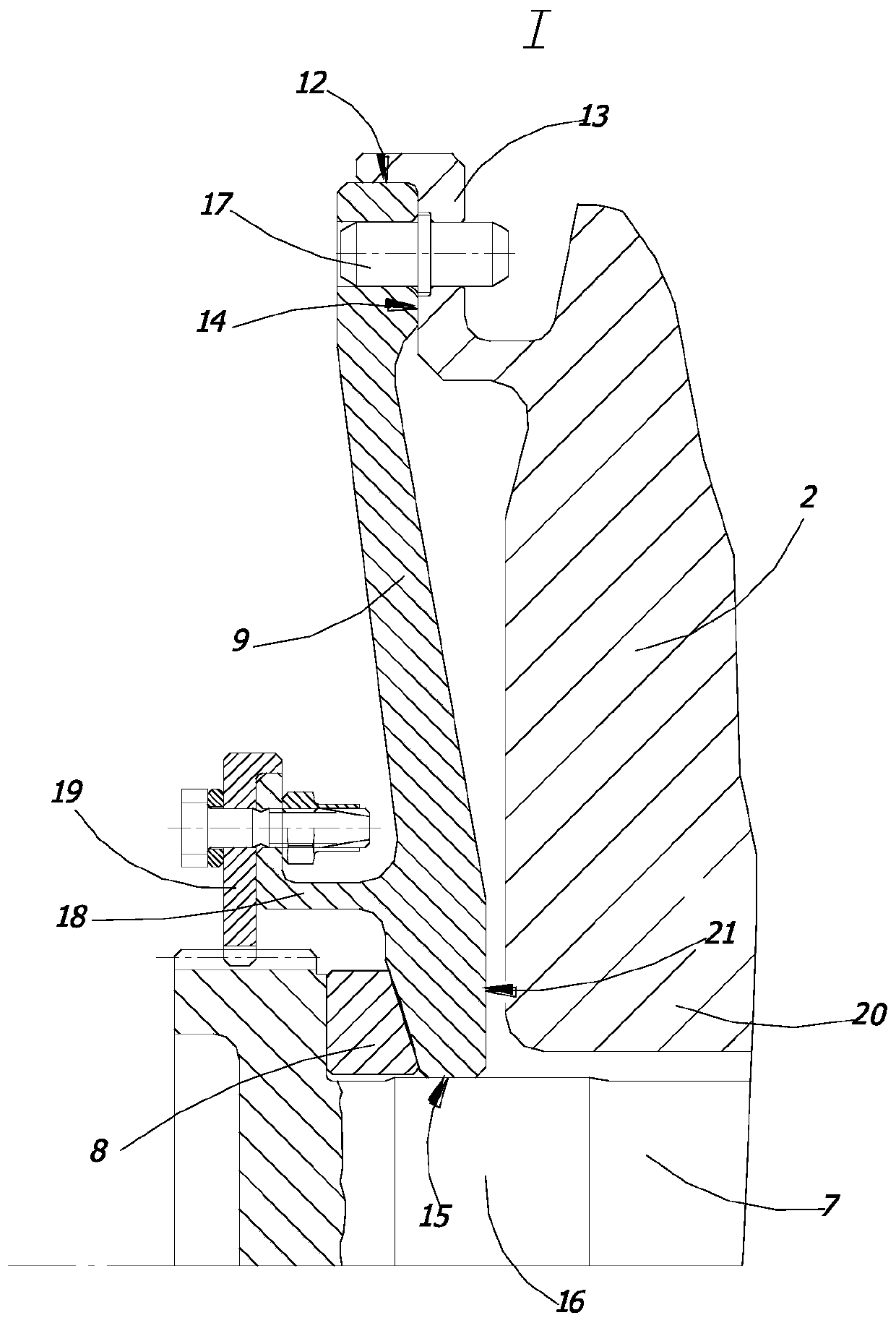

[0020] The multi-stage turbine rotor 1 comprises a first disc 2 , an intermediate disc 3 and a final disc 4 , which overhang the shaft 5 of the rotor 1 against a bearing 6 and pass through the center of a spherical washer 8 and an elastic member 9 Tension bolt 7 is connected. The last disc 4 with a radial flange 10 leading to the bearing 6 is attached to the shaft 5 by a bolt joint 11 .

[0021] The elastic member 9 having the first surface 12 is installed in the Z-shaped front flange 13 of the first disc 2 and is in contact with the end face 14 of the Z-shaped front flange 13, while the second surface 15 of the elastic member 9 is in contact with the tensioned The body 16 of the bolt 7 is in contact. The elastic member 9 rests against the Z-shaped front flange 13 of the first disc 2 and is fixed circumferentially with axial pins 17 and is manufactured with an L-shaped annular flange 18 on which is mounted The circumferential retainer 19 of the tension bolt 7 .

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com