An automatic control system and method for cementing annular pressure

An automatic control system and annular pressure technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve the problems of reducing the success rate of oil and gas well cementing construction, excessive fluctuations in annular pressure, and affecting Problems such as the cement annulus cementation quality in the annulus, achieving significant comprehensive benefits, saving rental costs, and improving cement cementation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meanings as commonly understood by those skilled in the art.

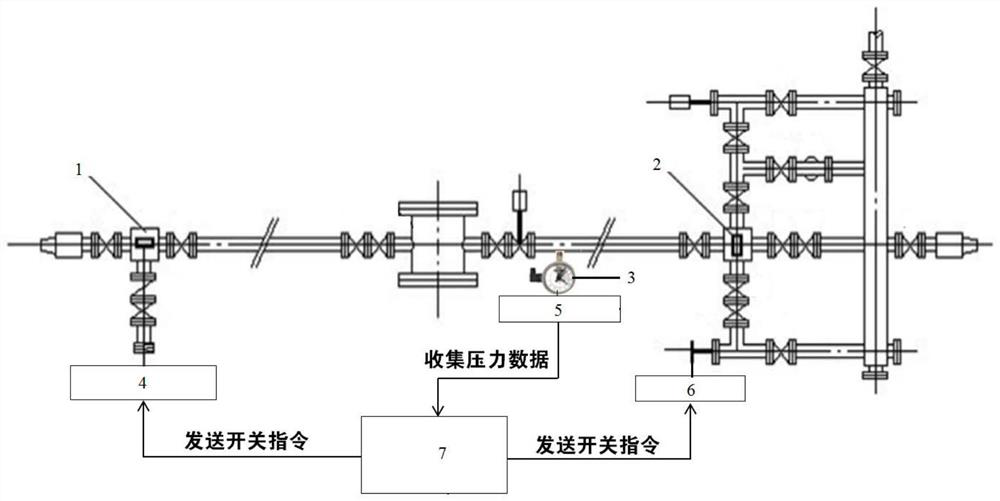

[0047] An embodiment of the present invention provides an automatic control system for cementing annular pressure. The automatic control system is used to control the annular pressure of the oil well annulus through a well control manifold. The well control manifold includes a kill manifold 1, a node A flow manifold 2 and a pressure gauge 3 for measuring the annular pressure, the automatic control system includes:

[0048] A pressure compensation pump 4 arranged on the kill manifold 1;

[0049] a hydraulic throttle valve 6 arranged on the throttle manifold 2; and

[0050] A pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com