The first one is to use the tensile steel bars on both sides of the column to bend upwards at 90° to anchor the steel bars, and the exposed horizontal length of the steel bars should not be less than 0.4L abE , and should extend to the inner edge of the longitudinal reinforcement on the outer side of the column, the coincident length of the anchored horizontal straight section of the

steel bar on both sides of the beam is greater than the section length of the column -100mm, and the number of steel bars in the horizontal straight section of the anchored

steel bar at the node is doubled, according to The specification requires that the spacing of the anchoring steel bars be ≥ 25mm. If the spacing of the steel bars in the anchored horizontal straight section cannot meet the requirements of the specification, it will cause quality defects and safety problems at the joints. At the same time, it is necessary to carry out the

dislocation layout design of the longitudinal reinforcement of the prefabricated beam on both sides, the design

workload and the difficulty of

prefabrication increase, and the degree of

standardization decreases. Asymmetric quality and safety issues

The second type is that the two prefabricated beams are anchored at the cast-in-place joints of the columns with tensile steel bars and end anchor heads. The anchor heads require that the anchorage length of the beam steel bars should not be less than 0.4L abE , extending through the central axis 5d of the column, using tensile longitudinal steel bars and adding end anchor heads for anchoring. Similarly, the prefabricated beam steel bars on both sides of the column coincide with a certain length in the anchored horizontal straight line section, and the steel bars at the nodes anchor the horizontal straight line section. The number of steel bars is doubled. If the

steel bar spacing or anchor head spacing of the horizontal lap section cannot meet the specification requirements, it will cause joint quality defects and safety problems. If the steel bar spacing or anchor head spacing is to be ensured,

prefabrication must also be increased. The width of the beam section increases the cost. At the same time, the design of the

dislocation layout of the longitudinal reinforcement of the prefabricated beam on both sides increases, the design

workload and the difficulty of

prefabrication increase, and the degree of

standardization decreases. There will be quality and safety problems of asymmetrical reinforcement arrangement of the beam

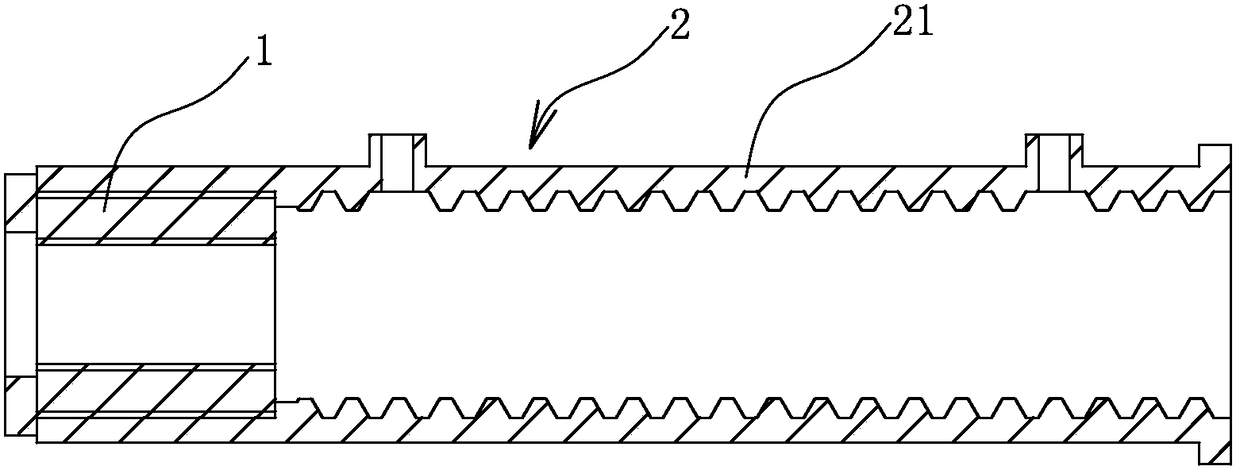

The third type is that two prefabricated beams are connected by mechanical connection at the cast-in-place joints of the two prefabricated beams, that is, mechanical sleeve connection. The horizontal

dislocation of the steel bars is not required, and the cross-sectional width of the beams does not need to be increased. However, the longitudinal steel bars at the joints are mechanically threaded. For sleeve connection, the steel bars at both ends of the connection must be accurately aligned without errors, which cannot be done on the construction site. Moreover, the threaded length of the long-end steel bars needs to reach the length of the mechanical connection sleeve to meet the hoisting requirements of prefabricated beams. After the mechanical sleeve is connected in place, the long-end steel bar exposes a certain length of exposed thread head, the tensile strength of the exposed thread head section is lower than the original tensile strength of the steel bar, and the tensile strength of the steel bar is reduced to the exposed thread thread The tensile strength of the head, that is, the steel bar should be used at a lower level, which wastes a lot of steel

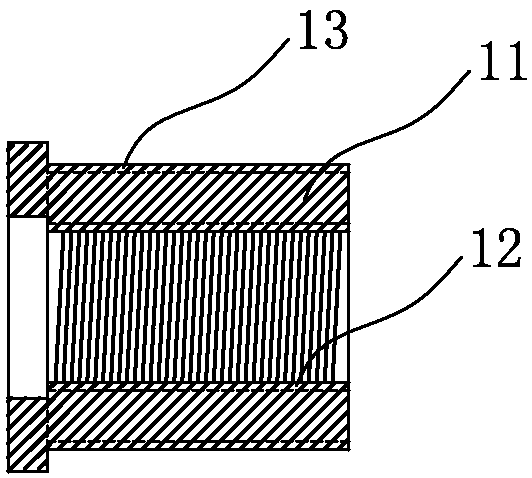

Fourth, the two prefabricated beams are connected by the grouting sleeve of the horizontal longitudinal reinforcement of the prefabricated beam at the cast-in-place node in the column. The reinforcement

layout does not need to be dislocated horizontally, and the cross-sectional width of the beam does not need to be increased. In order to meet the vertical hoisting of the prefabricated beams on both sides of the column Due to the requirements of site construction, full grouting sleeves are currently used to connect beam steel bars. However, due to the relatively long length of full grouting sleeves, such as connecting steel bars with a

diameter of Ф25, the length of full grouting sleeves is about 450mm, and the exposed total of the steel bars at both ends of the connection If the length is greater than 675mm, the length of the column section of the beam-column joint must be increased, which will increase the cost of construction

These existing problems have greatly affected the application process of prefabricated beams in prefabricated concrete frame structures, and the volume ratio of prefabricated

composite beams on the floor to prefabricated components is relatively high. The promotion and application of prefabricated

composite beams is conducive to improving assembly The prefabrication rate of the prefabricated building structure, the connection technology of the horizontal longitudinal reinforcement of the prefabricated composite beam of the beam-column cast-in-place joint of the prefabricated building has become the key technology for the popularization and application of the prefabricated concrete beam

Login to View More

Login to View More  Login to View More

Login to View More