a mn 4+ Doped tungstate red phosphor and preparation method thereof

A technology of red phosphor and tungstate, which is applied in the field of phosphor, can solve the problems of weak luminous intensity, unstable physical properties, and low output of phosphor, and achieve the effects of low manufacturing cost, excellent luminous performance, and stable luminous spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

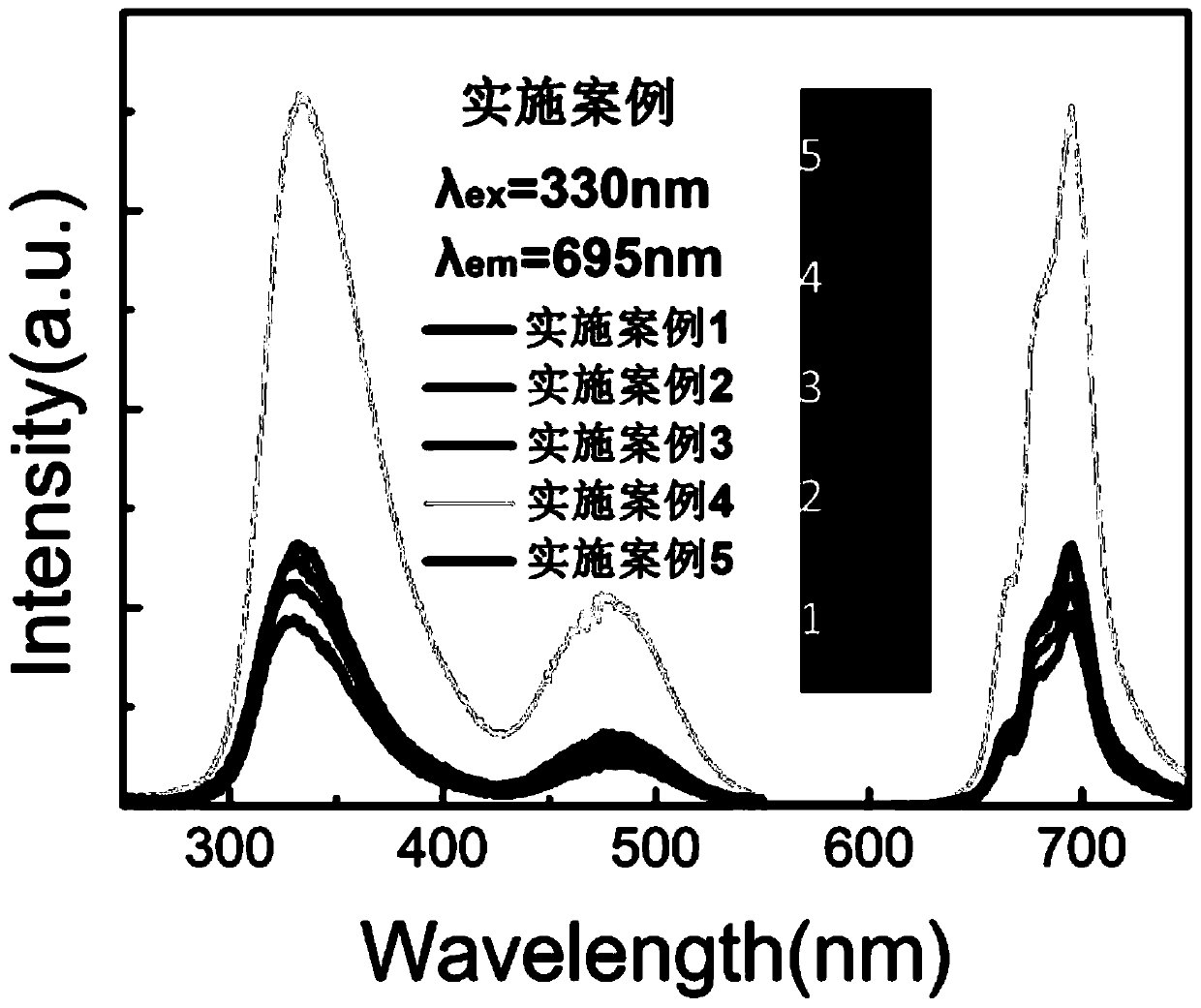

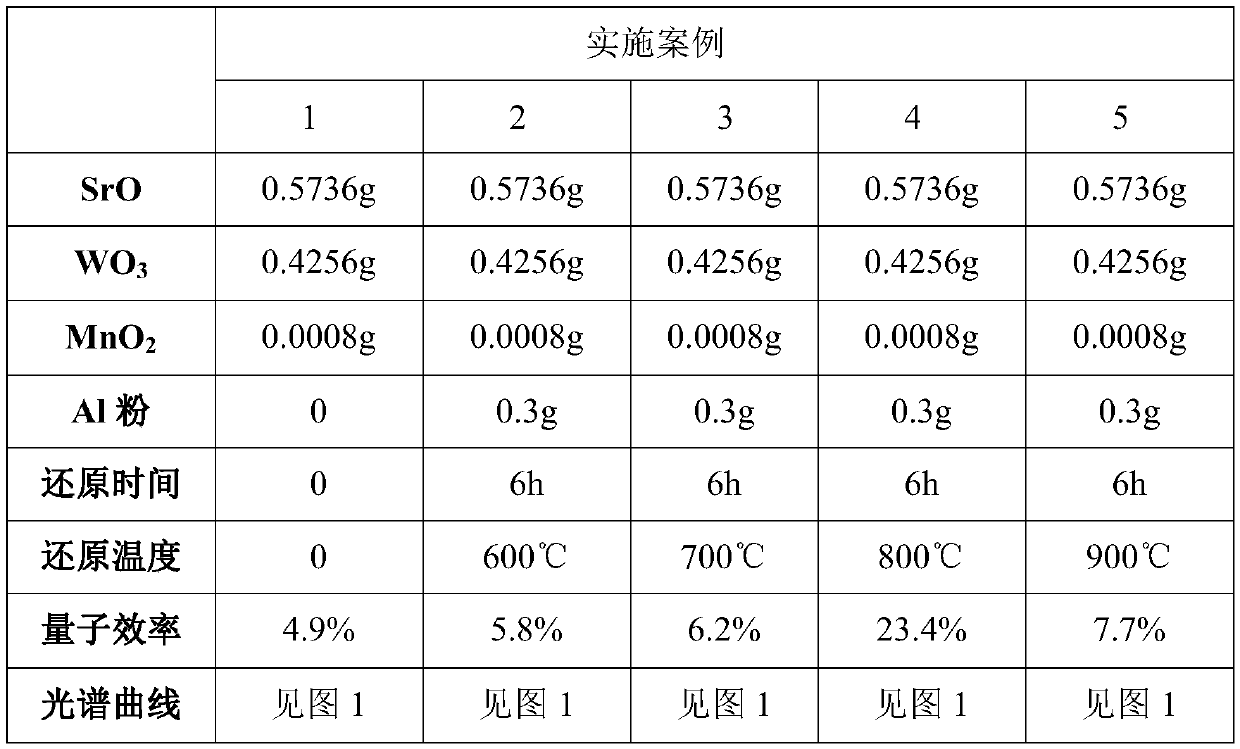

[0022] The invention provides a Mn 4+ The preparation method of the doped tungstate red fluorescent powder comprises the following steps:

[0023] (1) First weigh a certain quality of raw material powder, put it in an agate mortar and grind it for 30-60 minutes, then put it into a quartz crucible, and heat it in a high-temperature furnace at 1250-1300°C for 4-10 hours through solid-state reaction. Cool to room temperature to prepare a precursor, wherein the composition of the powder raw material is (in terms of oxide mass percentage): 0%3 +WO 3 +SiO2 2 +TiO 2 + GeO 2 ≤57.95%, 0%2 ≤0.14%;

[0024] (2) Weigh the Al powder and precursor according to the mass ratio of Al powder to precursor (0.03-1): 1, place Al powder and precursor in a crucible boat respectively, and place them in a vacuum tube furnace. After the system is evacuated to less than 0.1MPa, heat treatment is carried out at 0-900°C, and after reduction for 6 hours, it is naturally cooled to room temperature to o...

Embodiment 1

[0030] (1) First weigh a certain quality of raw material powder (CaO=0.4213g, WO 3 =0.5776g, MnO 2 =0.0011g), put it in an agate mortar and grind for 30-60min, then put it into a quartz crucible, heat it in a high-temperature furnace at 1250-1300°C for 4-10h through solid-state reaction, and cool to room temperature to obtain the precursor .

[0031] (2) Weigh 0.3g of Al powder and 1g of the precursor, place the Al powder and the precursor in a crucible boat respectively, and place them in a vacuum tube furnace. After the whole system is evacuated to less than 0.1MPa, the , heat treatment, after reduction for 6h, naturally cooled to room temperature, that is, to obtain Mn 4+ Doped tungstate red phosphor. During the whole preparation process, the Al powder and the precursor are always separated without contact, and the crucible boats are placed parallel to the left and right in the vacuum tube furnace, and the distance between the centers of the crucible boats placed in para...

Embodiment 2

[0033] (1) First weigh a certain quality of raw material powder (SrO=0.5736g, WO 3 =0.4256g, MnO 2 =0.0008g), put it in an agate mortar and grind for 30-60min, then put it into a quartz crucible, heat it in a high-temperature furnace at 1250-1300°C for 4-10h through solid-state reaction, and cool to room temperature to obtain the precursor .

[0034] (2) Weigh 0.3g of Al powder and 1g of precursor, place Al powder and precursor in a crucible boat respectively, and place them in a vacuum tube furnace. After the whole system is evacuated to less than 0.1MPa, the , heat treatment, after reduction for 6h, naturally cooled to room temperature, that is, to obtain Mn 4+ Doped tungstate red phosphor. During the whole preparation process, the Al powder and the precursor are always separated and not in contact, and the crucible boats are placed in parallel to the left and right in the vacuum tube furnace, and the mutual center distance of the crucible boats placed in parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com