Motor direct-driven brake-by-wire system with main/auxiliary cylinder and brake control method of system

A brake-by-wire and brake control technology, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve problems such as large fluctuations, high motor performance requirements, and long pressure build-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

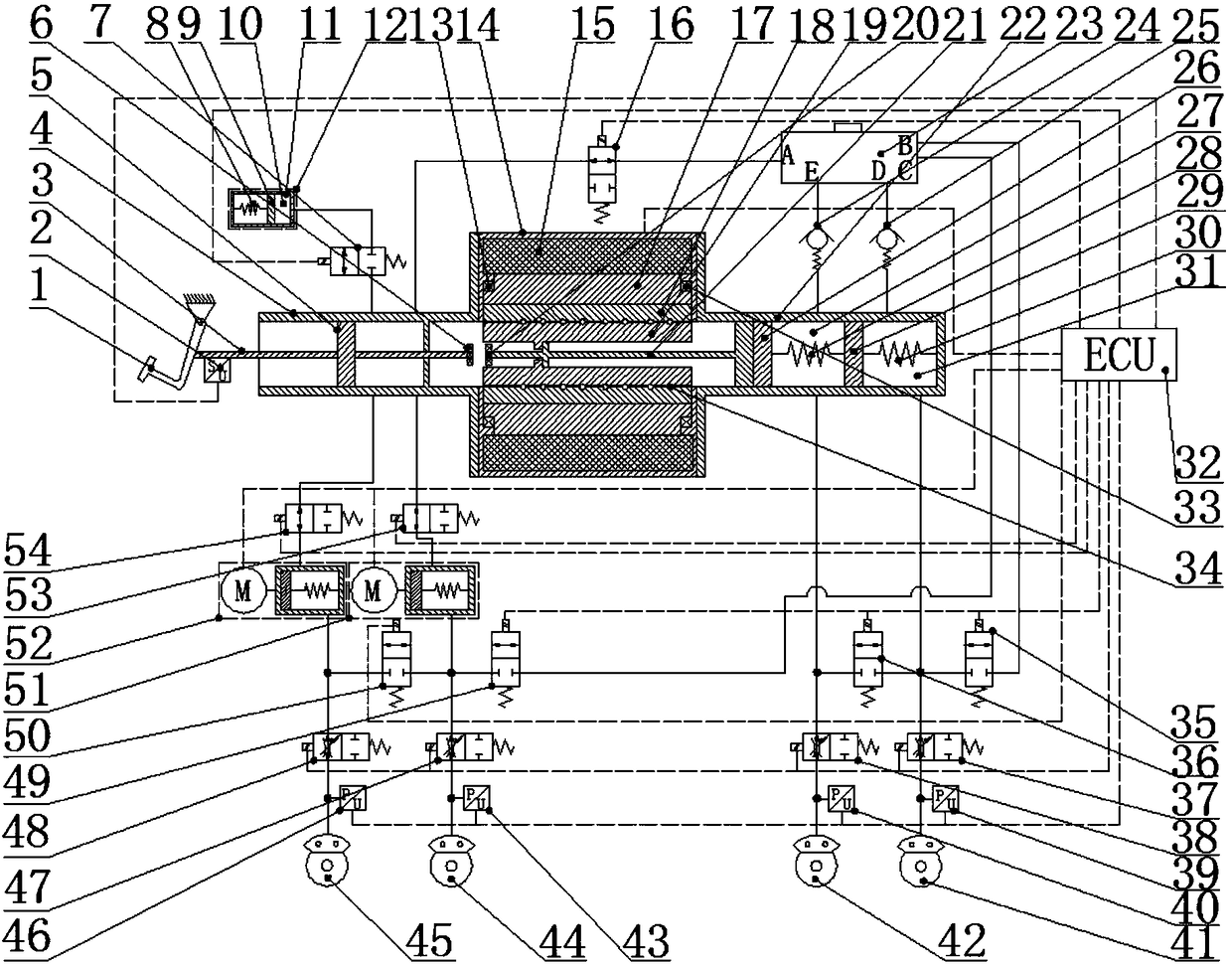

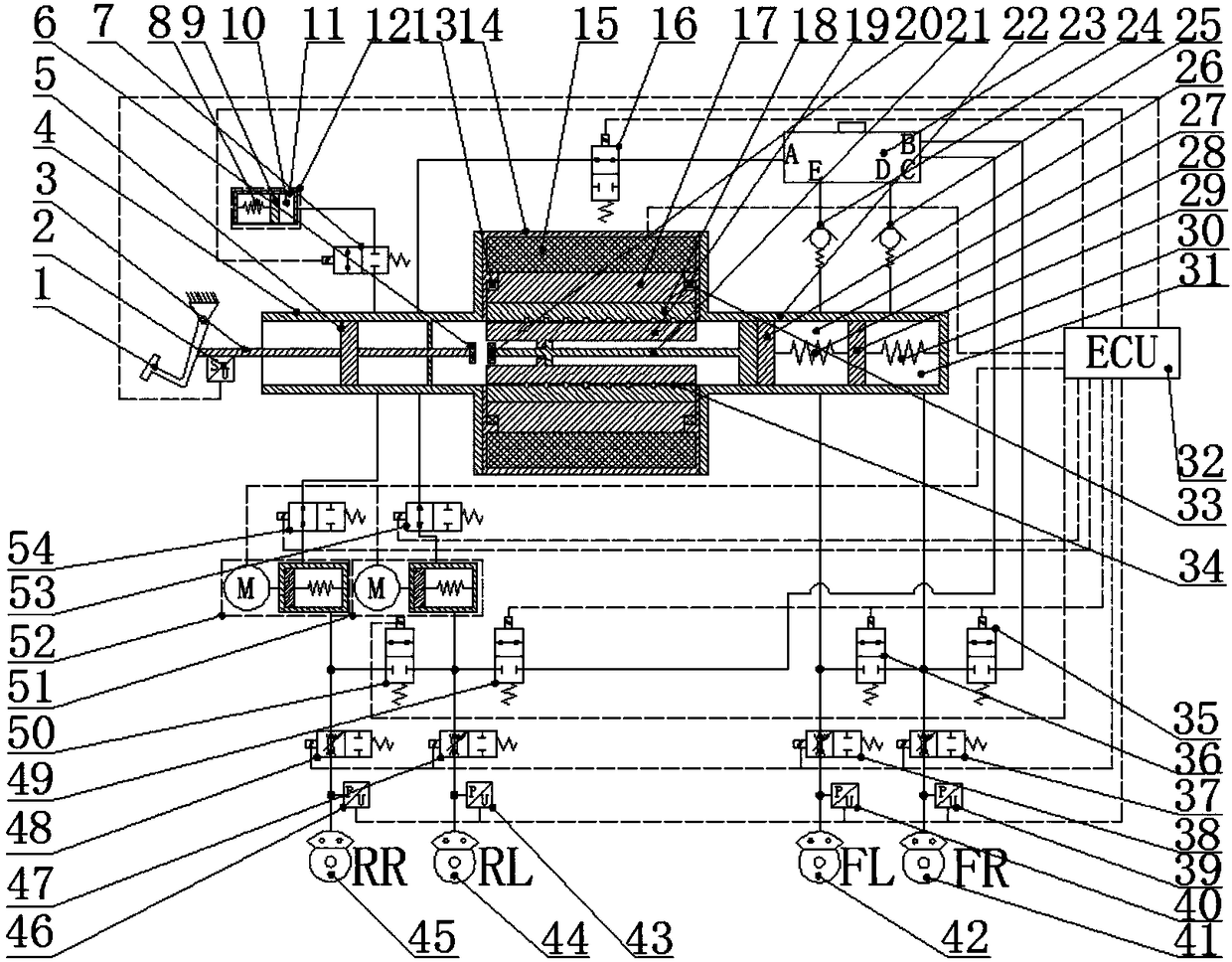

[0079] In order to further illustrate the technical solution of the present invention and the beneficial effects brought by it, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0080] The invention provides a motor direct-drive-by-wire brake system with main / auxiliary cylinders, which is composed of a brake pedal operating mechanism, an electronic control unit, an oil storage cup, a dual-chamber master cylinder braking module and a single-chamber auxiliary cylinder braking module.

[0081] The brake pedal operating mechanism is composed of a pedal mechanism, a pedal feeling simulator 12, a first normally closed switch solenoid valve 7 and a first normally open switch solenoid valve 16;

[0082] Such as figure 1As shown, the pedal mechanism is composed of a pedal 1, a displacement sensor 2, a pedal push rod 3, a pedal push rod housing 4, a pedal piston 5 and a first rubber reaction disc 6; wherein the pedal 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com