Automatic pattern arrangement machine for decorative sequins

A layout machine and sequin technology, which is applied in the direction of decorative art and the process for producing decorative surface effects, etc., can solve the problems of easy burr on the edge, affect the appearance, and large area, and achieve smooth edges, fine patterns, and precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

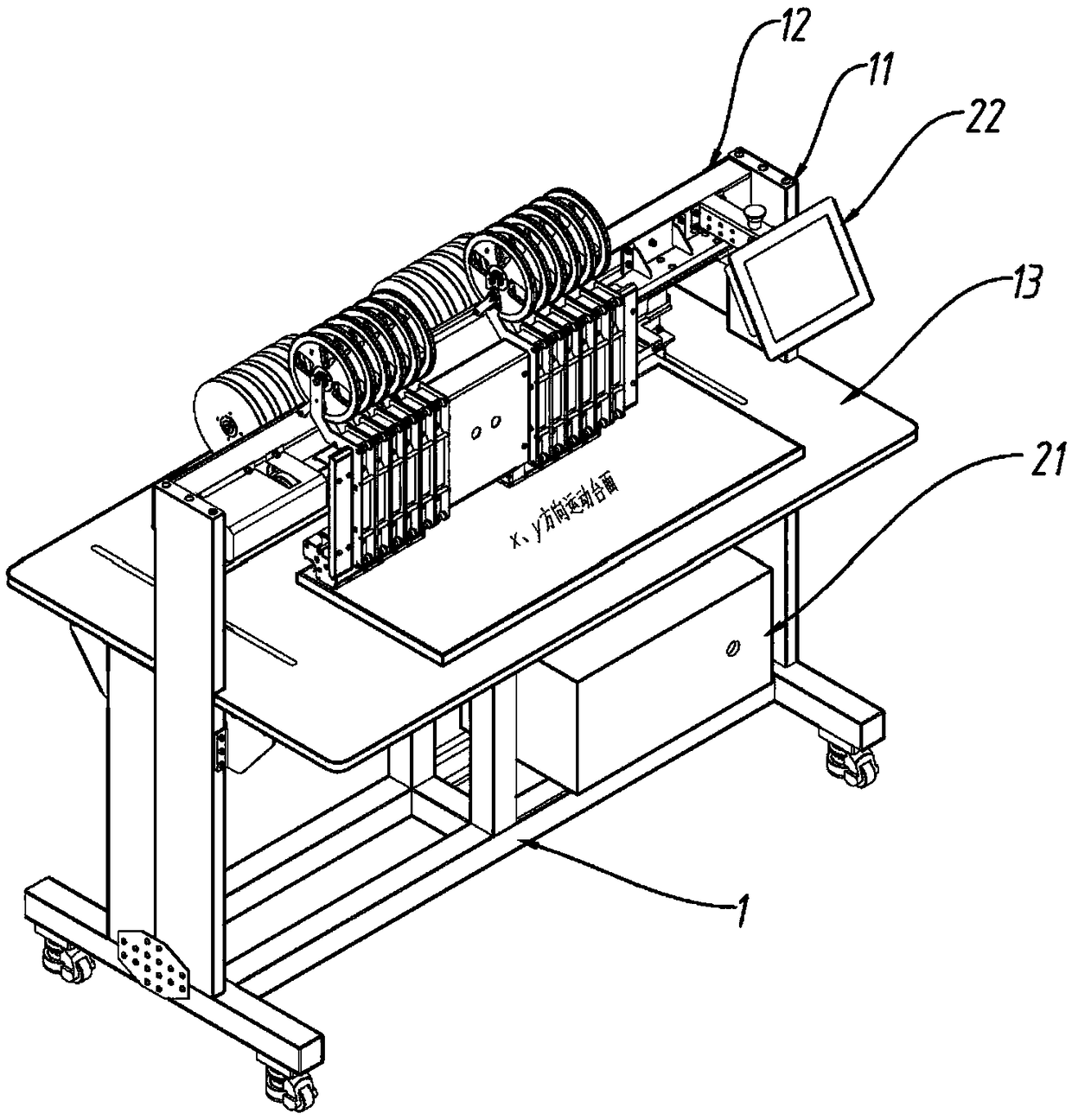

[0024] An automatic layout machine for decorative sequins of the present invention is composed of a frame 1 , a control device 2 , a color-changing drive device 3 , a sequin stamping device group 4 and a positioning device 5 . Wherein, the frame 1 is a table-top component composed of uprights 11 , crosspieces 12 and table tops 13 , and the two ends of the crosspieces 12 are fixed on the tops of two uprights 11 .

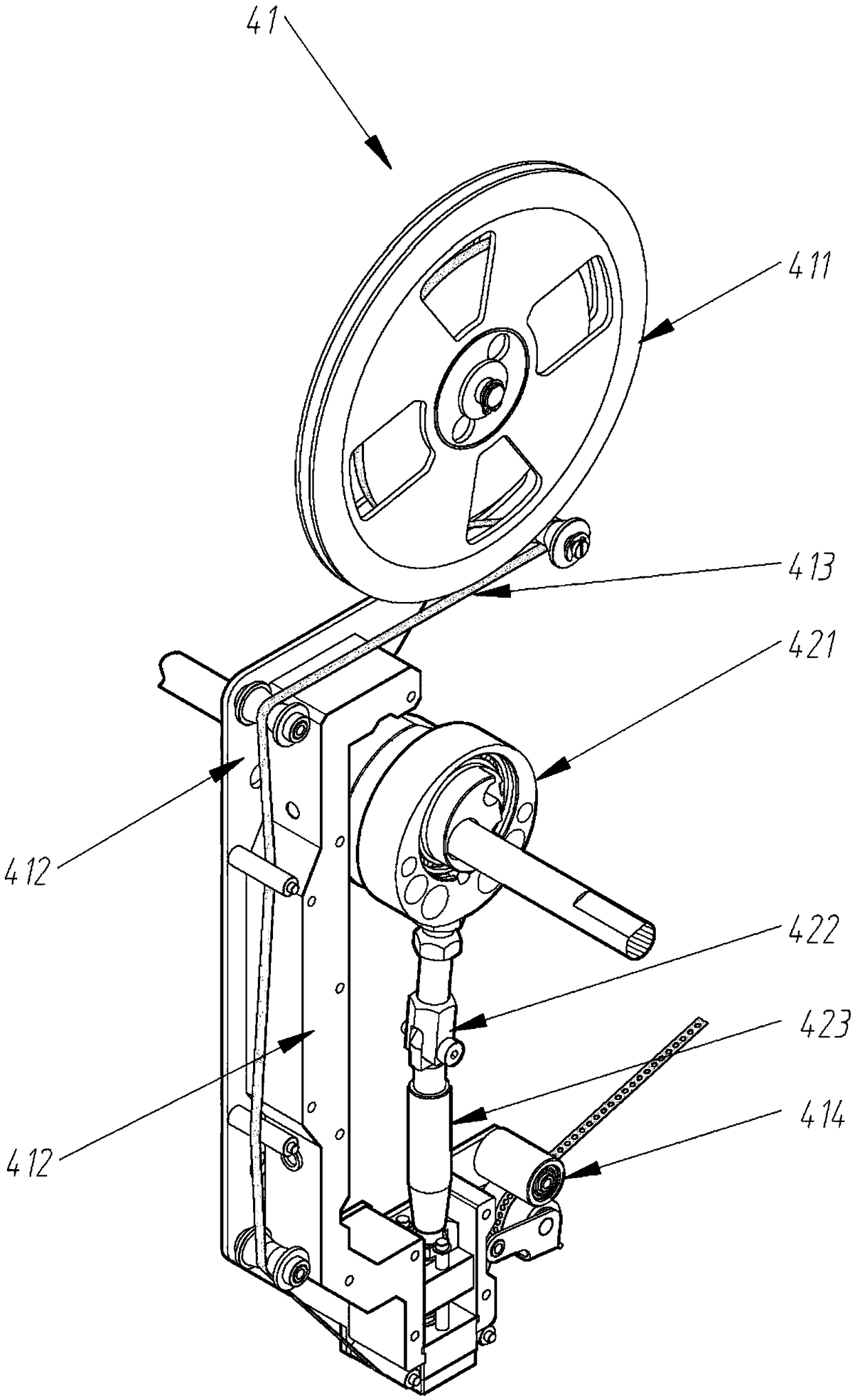

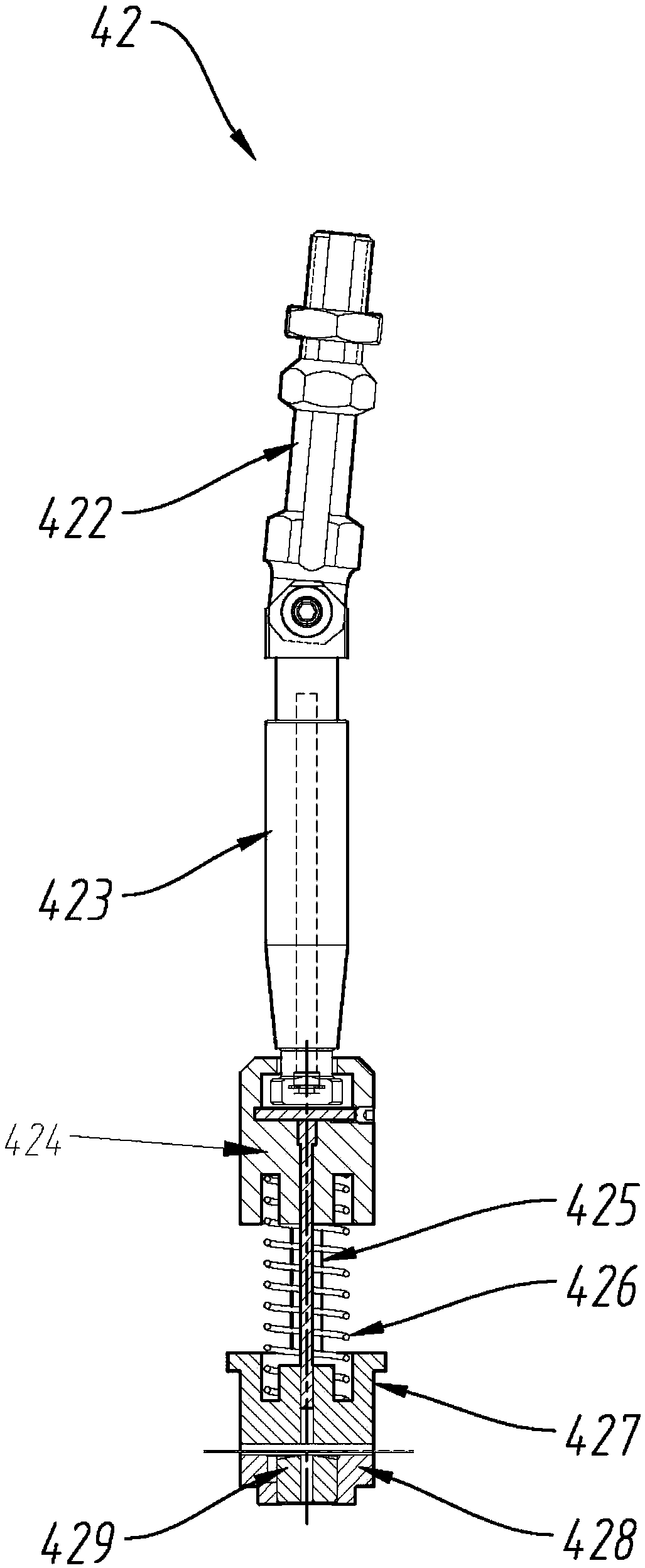

[0025] The color-changing driving device 3 is used to drive the sequin punching device 4 to move horizontally and linearly, and it is installed at one end of the crosspiece 12 . The color-changing driving device 3 is composed of a driving motor 31 , a screw rod 321 , a nut 322 , a connecting plate 33 , and a disk control positioning device 34 . Wherein, the driving motor 31 is fixedly connected with the screw rod 321, and the screw rod 321 cooperates with the nut 322 to push the nut 322 to move forward and backward. The connecting plate 33 is connected between the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com