Forming structure and method of valve blade

A technology of valve blades and forming structures, which is applied in metal rolling and other directions, can solve the problems of lack of blade strength and stability, and achieve the effects of convenient operation, enhanced strength and stability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

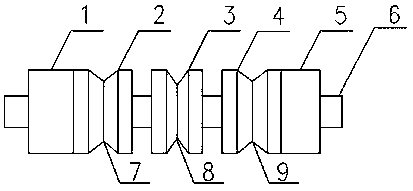

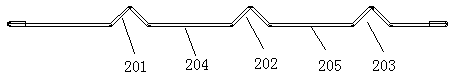

[0025] In the accompanying drawings: a forming structure of a valve blade, including a roll device; it is characterized in that: the roll device includes a shaft 6, a left roll 1 and a right roll 5 are arranged on the shaft 6, and the left roll 1 and the right roll The first roll 2, the second roll 3, and the third roll 4 are arranged between the rolls 5; the left roll 1 and the right roll 5 are set to be cylindrical, and their inner holes match the outer diameter of the shaft; The outer surface of the first roll 2 is provided with a triangular circumferential groove A7, the outer surface of the second roll 3 is provided with a triangular circumferential groove B8, and the outer surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com