Straw biomass granulator

A biomass pellet and pellet machine technology, which is applied in the fields of biofuel, die extrusion pelletization, waste fuel, etc., can solve the problems of waste of raw materials and low production capacity, and achieve the effect of good energy saving, high production capacity and precise coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

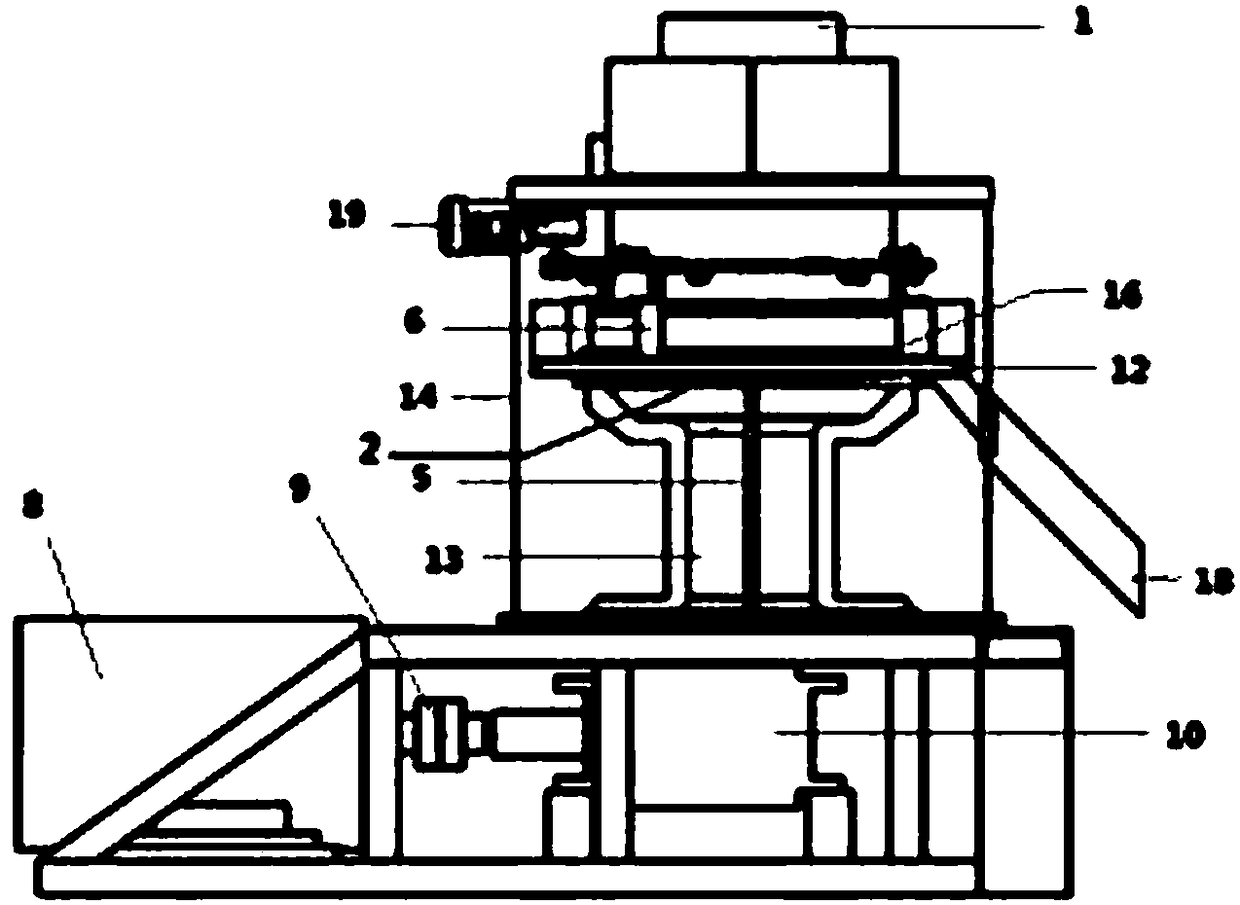

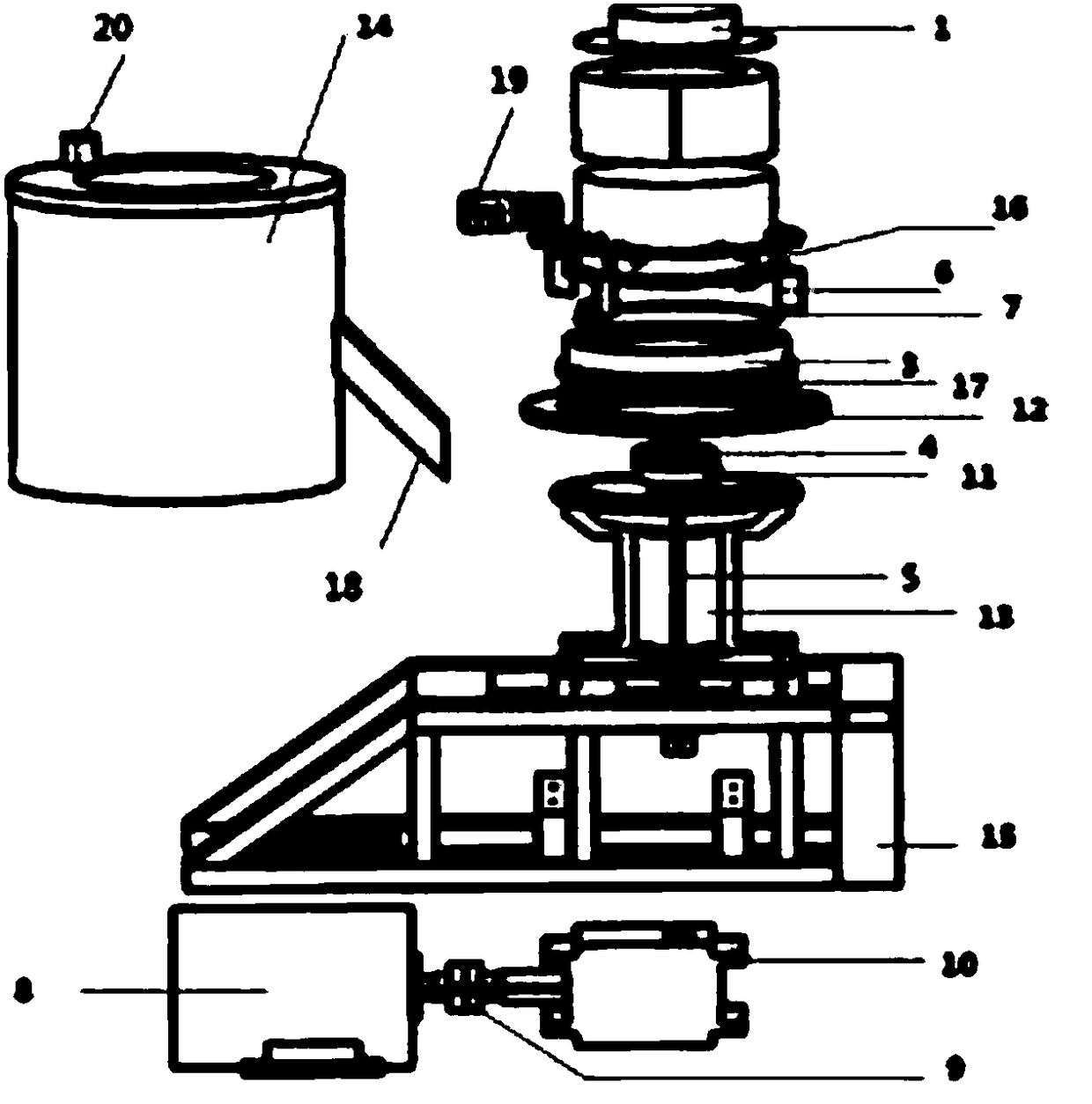

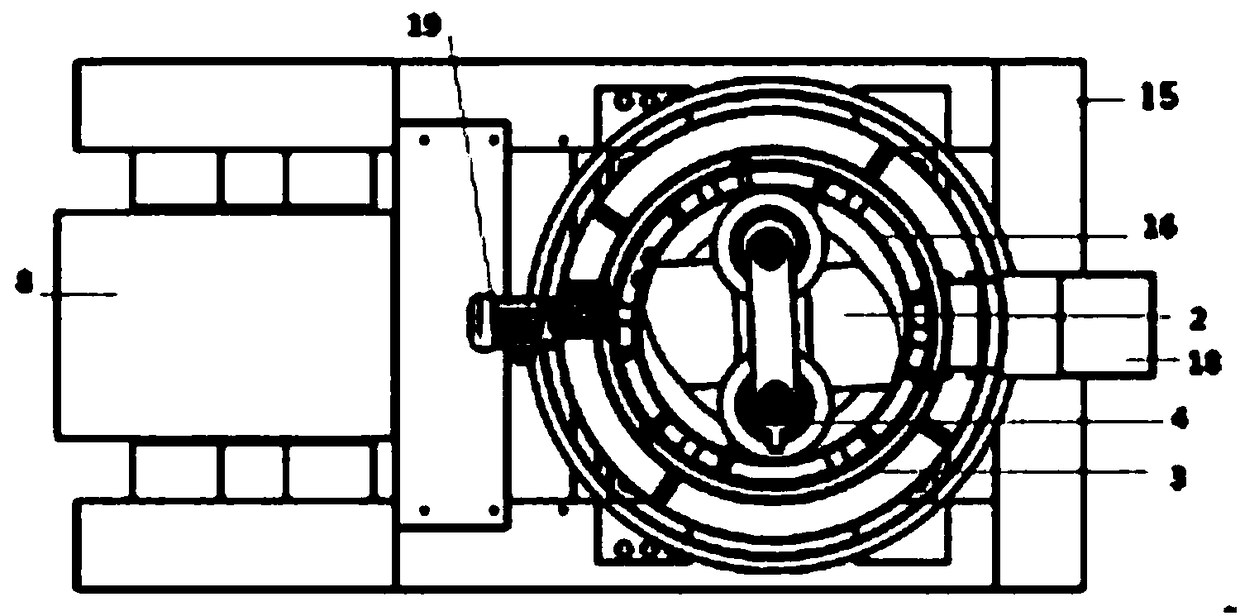

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, a biomass pellet machine includes a feed port 1, a turning plate 2, a ring die assembly 3, a pressing wheel 4 and a pressing wheel 11 through an eccentric shaft, an eccentric shaft adjusting ring, a connecting plate spline and a connecting plate Connected to the power system and set within the circumference of the ring die assembly 3. The main shaft 5 coincides with the axis of the ring die assembly 3. A scraper 6 is provided on the outside of the ring die assembly 3. After the material enters the feed port, the main motor 8 The speed reducer 10 and the main shaft 5 drive the press wheels 4 and 11 to rotate, feed the material into the gap between the press wheel and the ring die assembly, and scrape the particles formed in the ring die hole by the scraper 6, and then discharge the material. At the same time, the dust is removed through the dust removal interface 20.

[0042] T...

Embodiment 2

[0048] Similar to Example 1, the difference is that there is no heating element compression flange 16 above the ring mold, and a heating element 17 is provided below the ring mold assembly 3, and a groove is provided at the lower part of the ring mold assembly 3 for placement The heating element 17, the groove and the annular mold bottom plate 12 together prevent the heating element from contacting the dry material, thereby causing safety hazards.

[0049] The heating element 17 adopts an electric heating rod.

Embodiment 3

[0051] Similar to Embodiment 1, the difference is that a heating element 7 is provided above the ring die assembly 3, and a heating element 17 is provided below. Corresponding to the upper and lower parts of the ring die assembly 3, grooves are provided for placing the heating element 7 Together with 17, the groove, the compression flange 16 and the annular mold bottom plate 12, prevent the electric heating element from contacting the dry material and cause safety hazards.

[0052] Both heating elements 7 and 17 use electric heating rods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com