Indigo blue automatic delivery method

An indigo, automatic technology, applied in the field of printing and dyeing, can solve the problems of low product compliance rate, unstable product quality, and many uncontrollable factors, and achieve the effect of high product compliance rate, reduction of uncontrollable factors, and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

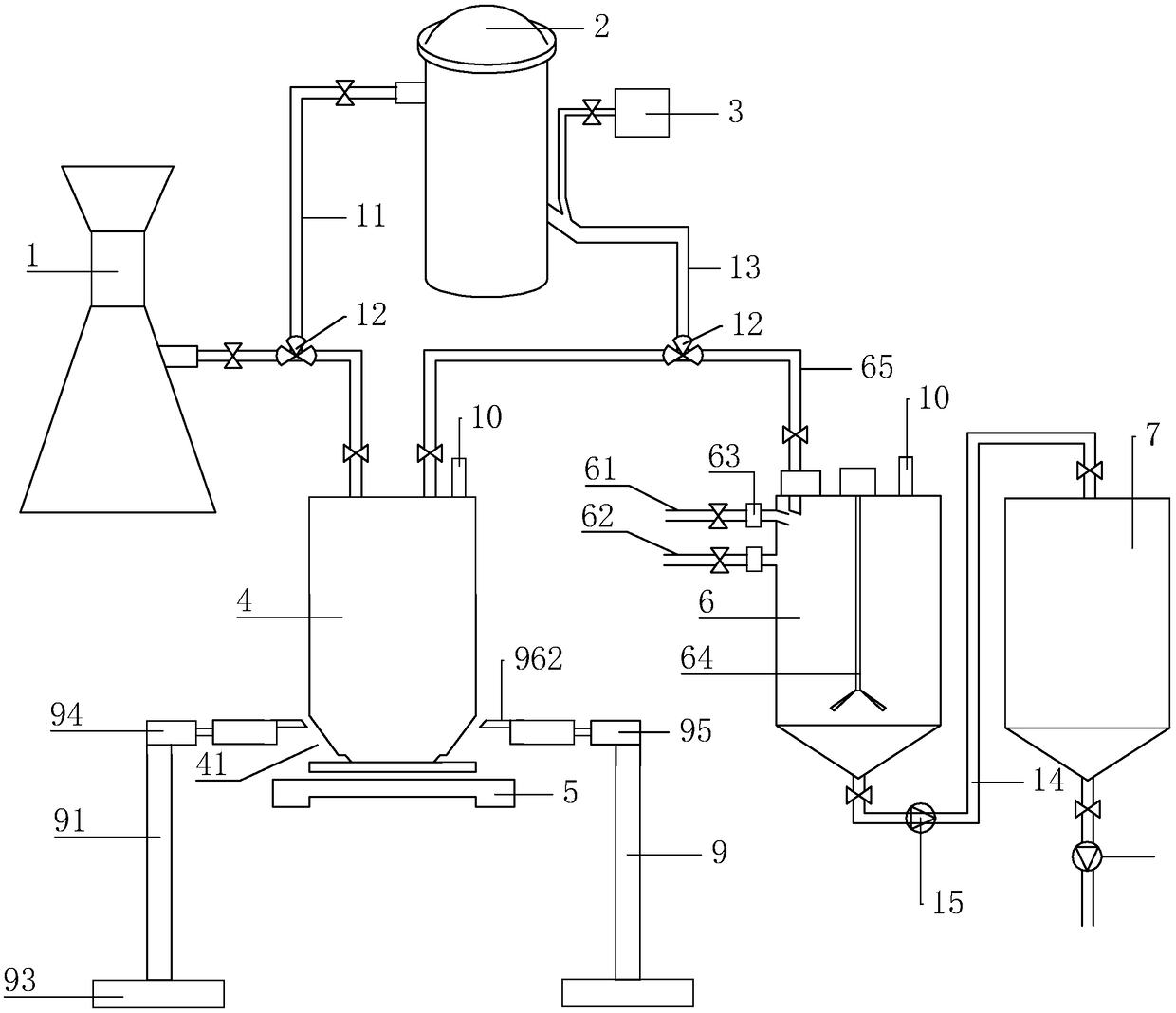

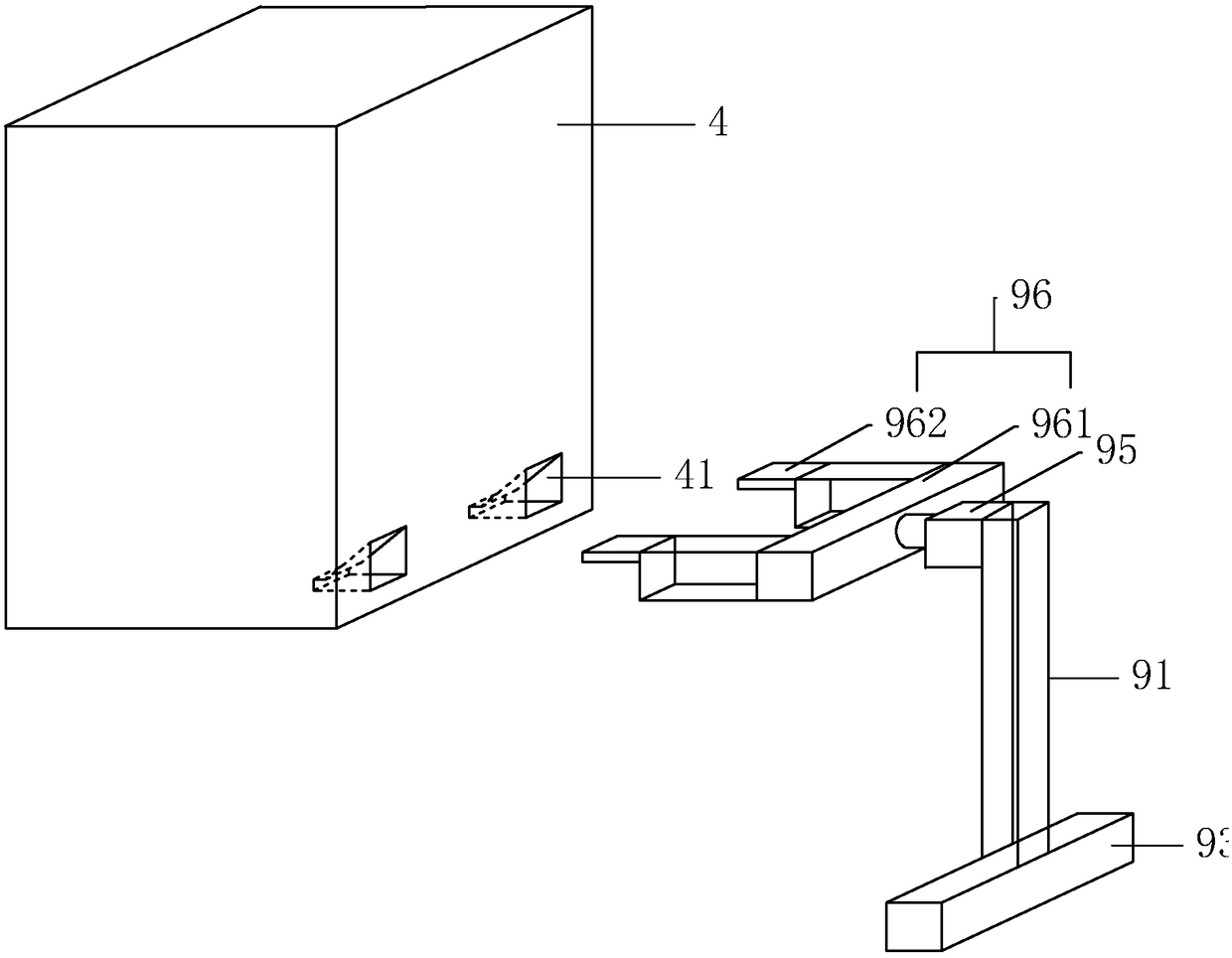

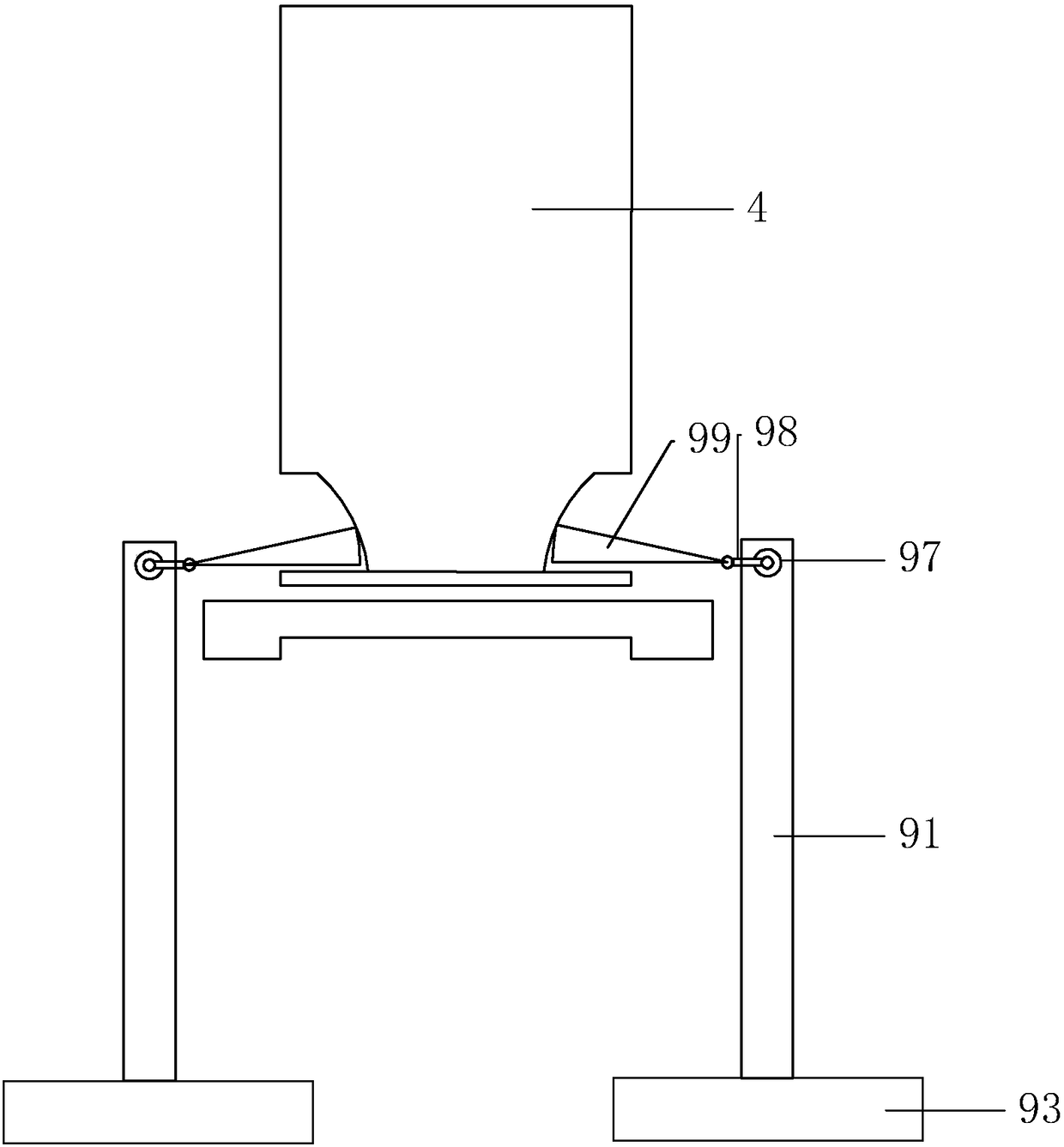

[0025] refer to Figure 1-5 As shown, a kind of indigo automatic dispensing method of the present embodiment, used device comprises unpacking machine 1, vacuum feeder 2, compressed air tank 3, weighing bucket 4, the weight sensor 5 that is positioned at weighing bucket 4, The chemical material barrel 6 and the storage tank 7 are connected through the first pipeline 11 between the discharge port of the material collector of the unpacking machine 1 and the feed port of the vacuum feeder 2. For the convenience of maintenance, the first pipeline 11 is close to the unpacking machine The discharge port of the material collector of 1 and the feed port of the vacuum feeder 2 are respectively provided with valves. When the distribution device is in working condition, the valve is in the normally open state, and the discharge pipe of the weighi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com