3D printer provided with air filtering device

An air filter device, 3D printer technology, applied in the field of 3D printing, can solve problems such as operator health threats, affecting air quality, affecting studio air quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

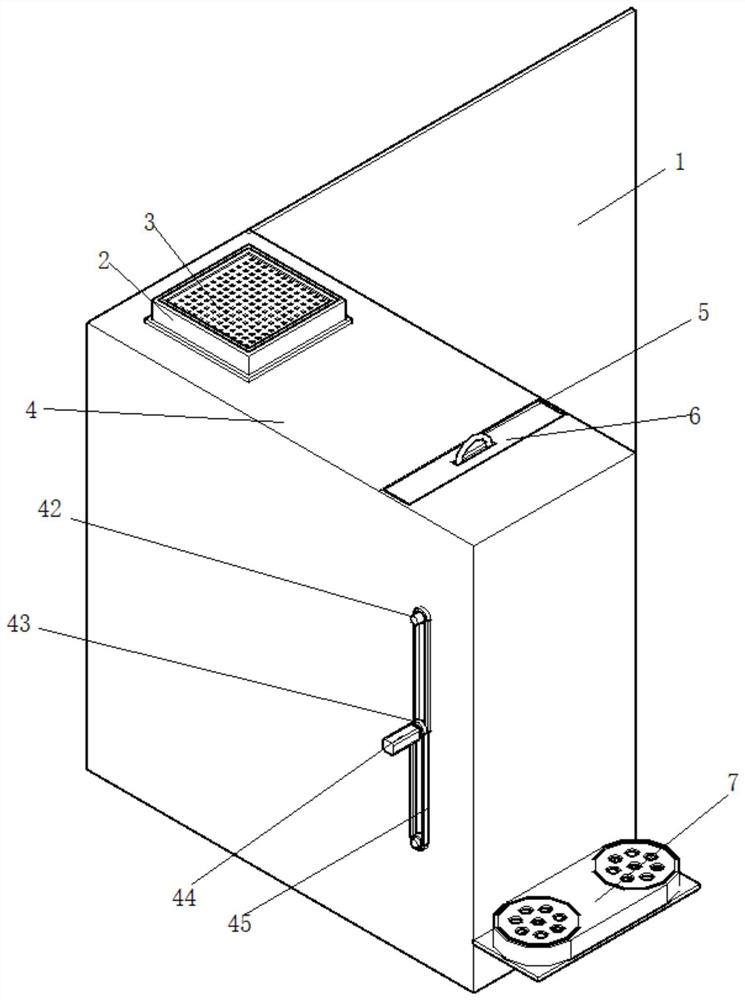

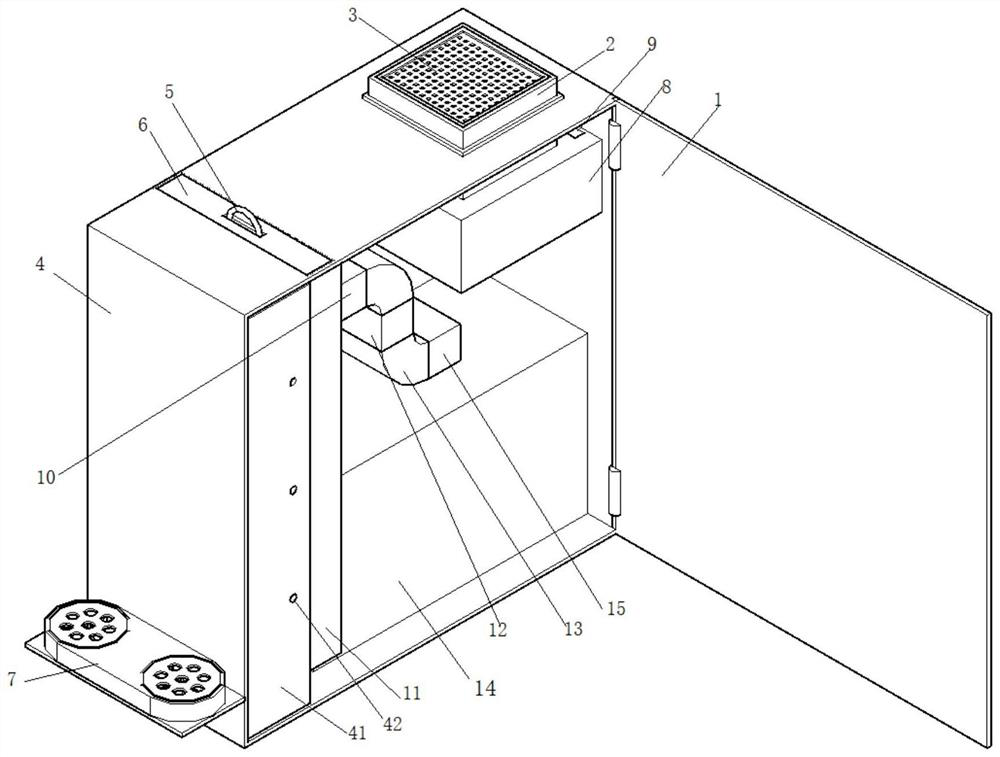

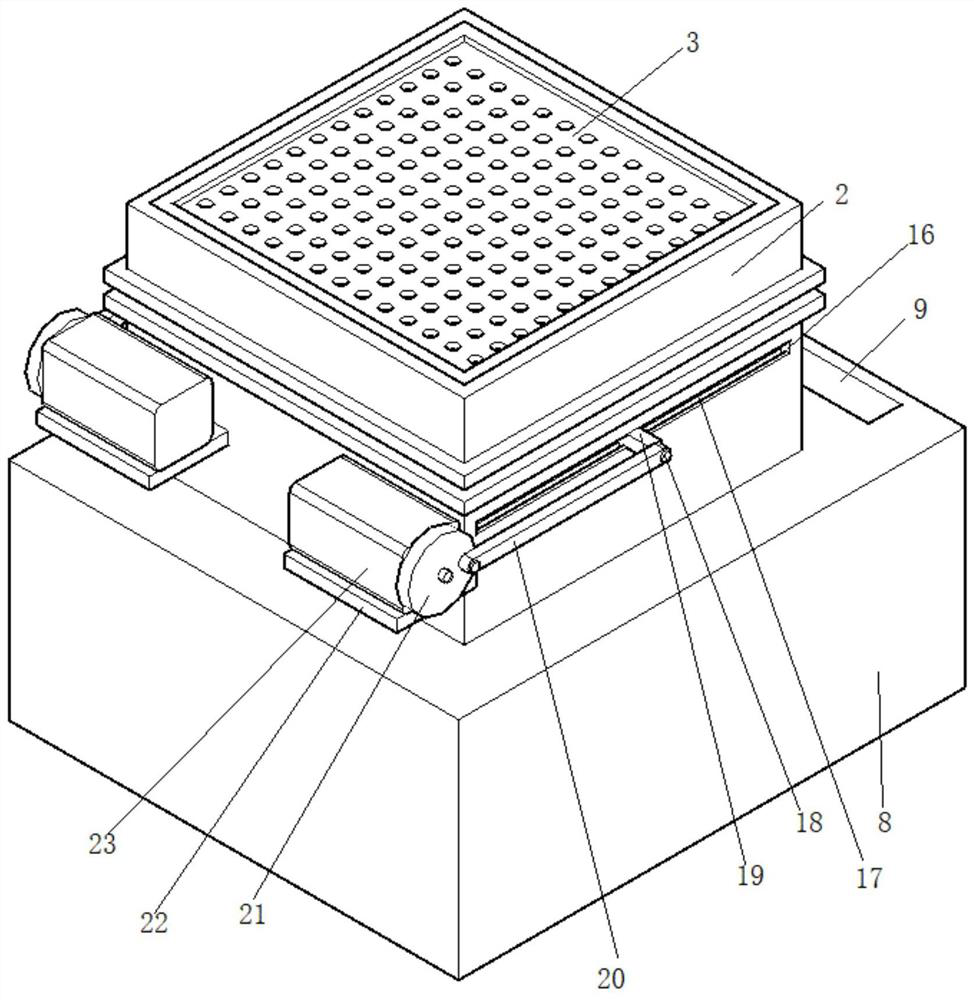

[0034] Such as Figures 1 to 15 As shown, the present embodiment provides a 3D printer with an air filter, comprising a box body 4 and a sealed door 1 hinged on one side of the box body, the inside of the box body 4 is provided with a printing assembly 14, and the printing assembly The top of 14 is provided with the air inlet that is fixed on the box body 4, and the below of described air inlet and the top that is positioned at printing assembly 14 is provided with the ash receiving box that is fixed on the box body 4, and one of described ash receiving box The side is provided with the installation groove 11 that is fixed on the box body 4, and the inside of the installation groove 11 is plugged with an air filter box, and one side of the air filter box is fixedly provided with a transition box 41 located inside the box body. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com