Container type organic waste gas adsorption purification-catalytic combustion regeneration skid-mounted device

An organic waste gas, catalytic combustion technology, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems of low equipment purification rate, high energy consumption, large equipment footprint, etc., and achieve high purification efficiency and good adsorption performance. , the effect of small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

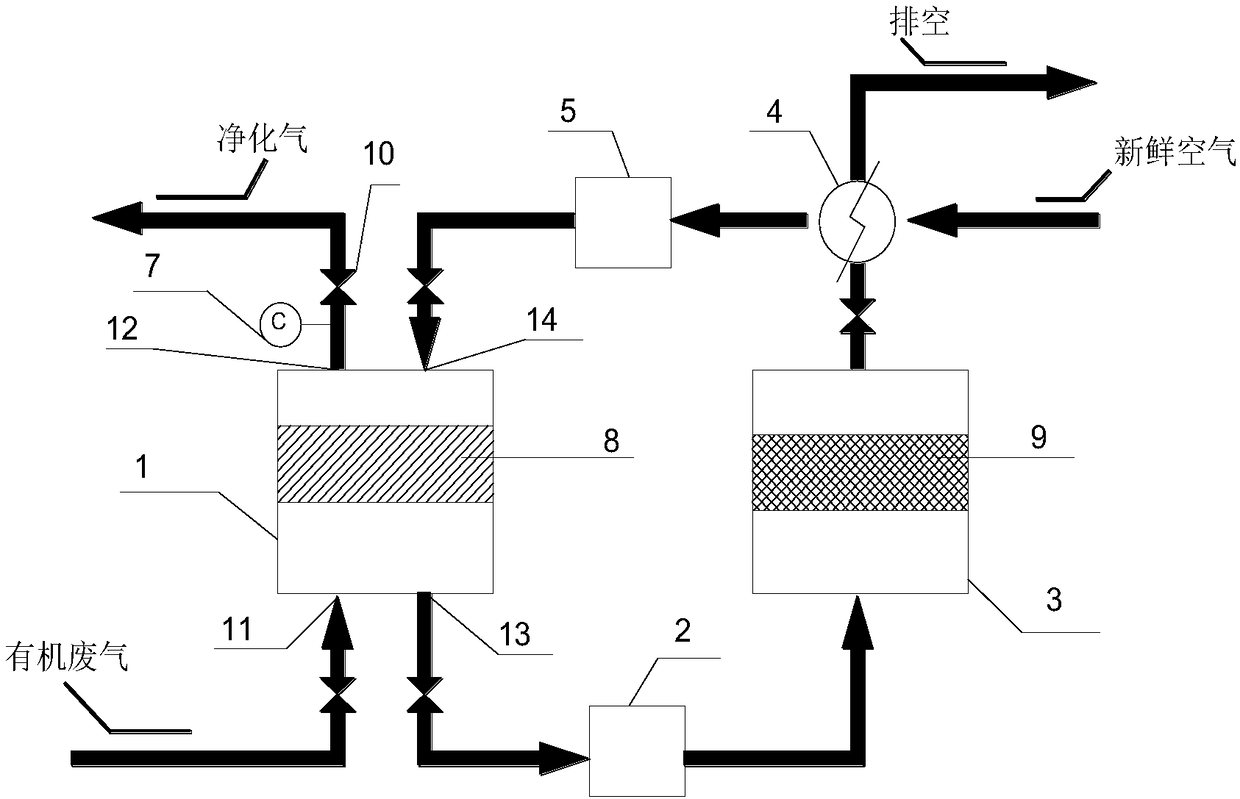

[0032] See figure 1 , 2 , the present invention provides a container-type organic waste gas adsorption and purification-catalytic combustion regeneration skid-mounted device, the specific composition structure is: adsorption system (1), which is an adsorption tower with a 2400*1500*2000 cuboid structure, and 1500kg of adsorbent is installed inside, and the adsorption The types are columnar coconut shell activated carbon, microporous and macroporous molecular sieves, with three temperature monitoring points on the upper, middle and lower; catalytic combustion temperature control system (2), equipped with 2 sets of 20KW heating tubes, and the outlet section is equipped with thermocouple temperature monitoring Catalyzed combustion reaction system (3) is provided with 5 layers of catalysts, the first layer is honeycomb ceramic type noble metal Pd catalyst, 2-3 layer is honeycomb ceramic type composite oxide catalyst, 4-5 is honeycomb ceramic type noble metal Pt catalyst, catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com