Automated online monitor for drilling fluid lubricity

A drilling fluid and lubricity technology, applied in the field of drilling fluid lubricity measurement equipment, to reduce the impact, solve the volatilization problem, and improve the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

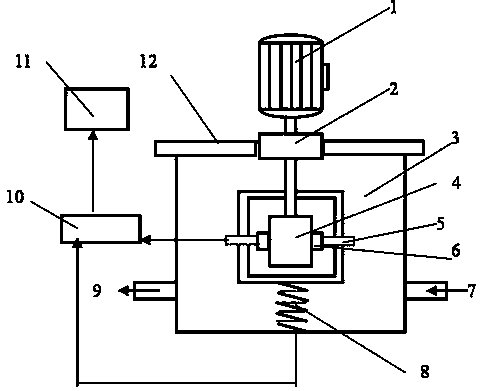

[0018] see figure 1 , the drilling fluid lubricity automatic online monitor includes a sealed sample chamber 3, a constant speed motor 1, a friction ring 4, a friction block 6, an afterburner and a pressure measuring element 5, a torque measuring element 8, a data acquisition box 10 and a computer 11, The sealed sample chamber is connected to the drilling fluid sample inlet and the drilling fluid sample outlet respectively; the constant speed motor 1 is connected to the transmission shaft, the transmission shaft extends into the sealed sample chamber 3 and the lower end of the transmission shaft is connected to the friction ring 4, and the transmission shaft and the sealed sample chamber The dynamic seal for the kettle is used between 3, that is, the mechanical seal 2 is sealed; the torque measuring element 8 is installed at the bottom of the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com