Prefabricated plate wall inter-layer transverse seam connecting joint

A technology for connecting nodes and prefabricated panels, which is applied in construction and building construction, etc., can solve the problems of high precision requirements, high construction difficulty, and impact on the construction process of steel reinforcement holes in upper-layer slab wall modules, so as to ensure the connection strength and quality, reduce the workload of formwork support, and reduce the effect of on-site welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

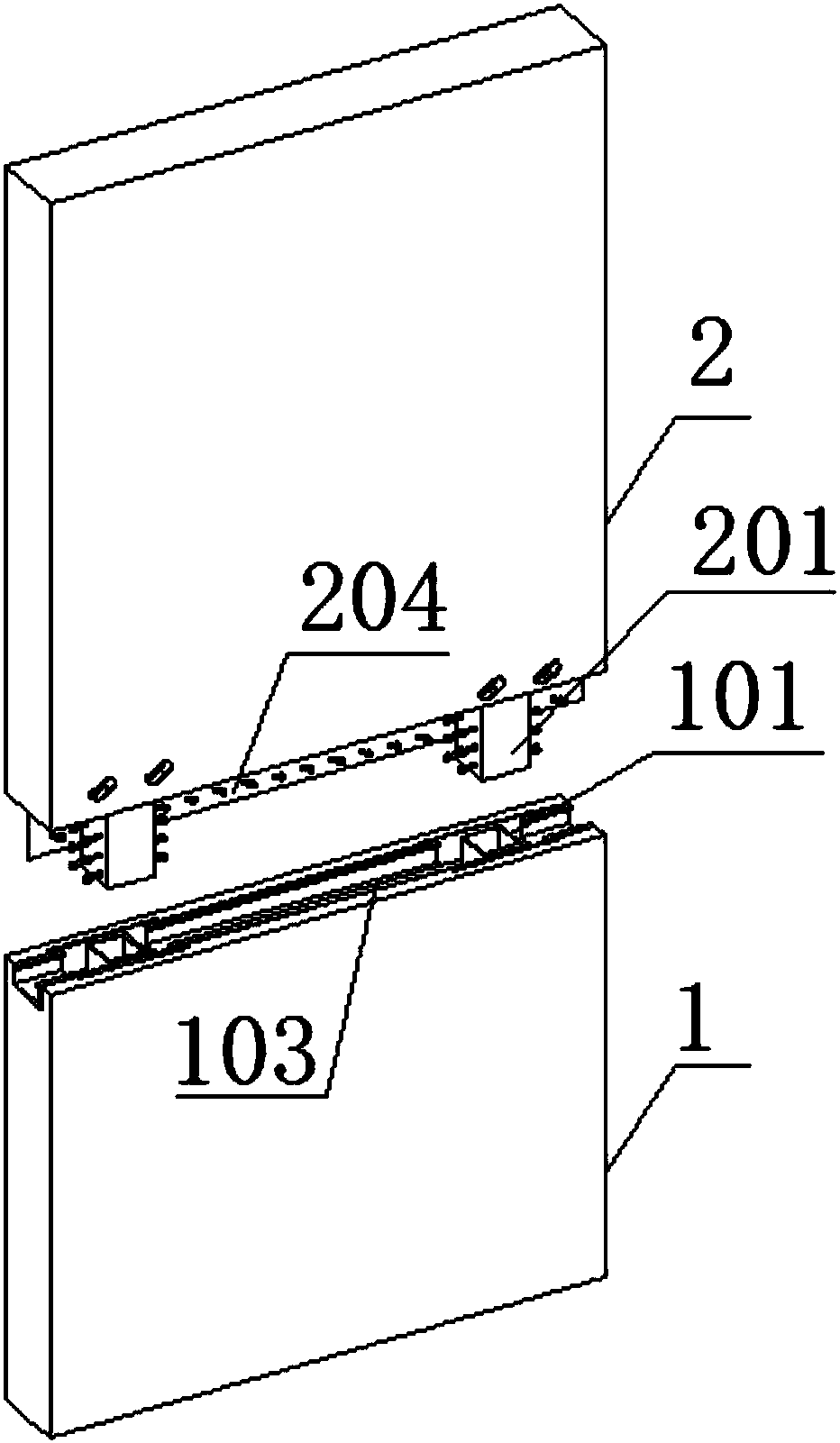

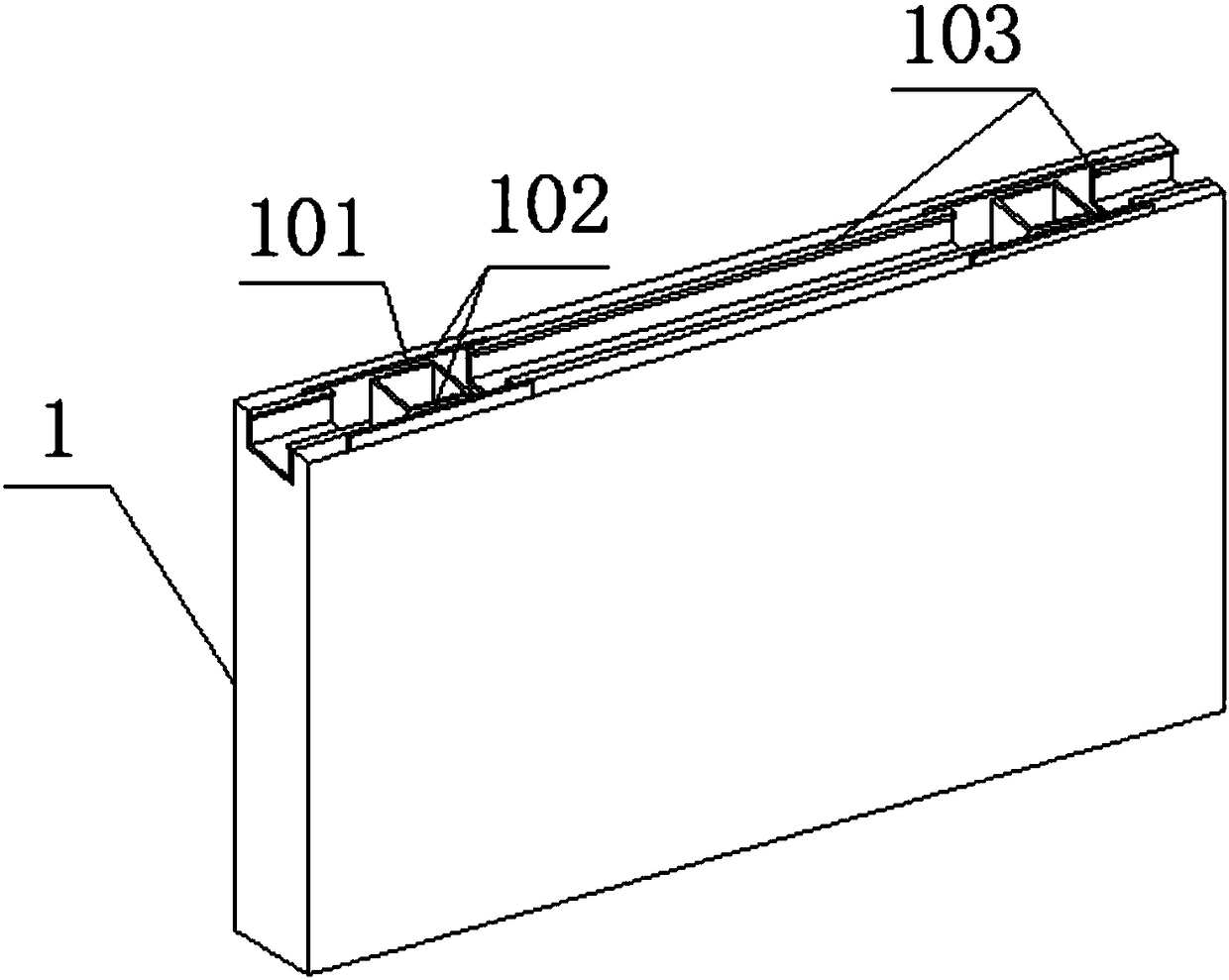

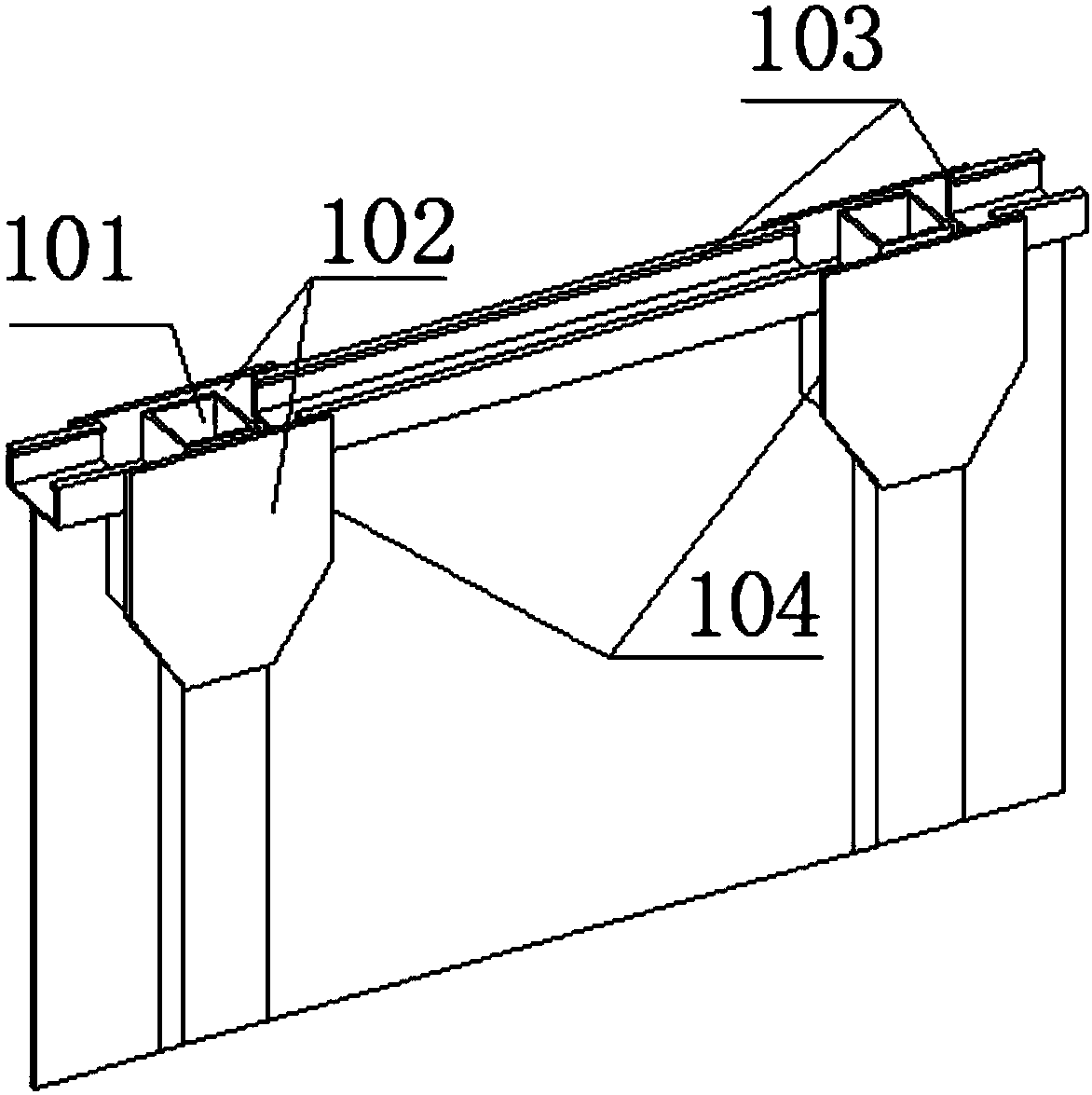

[0037] refer to Figure 1-8 , a prefabricated board wall interlayer transverse seam connection node, including the upper connection node of the lower board wall module 1 and the lower end connection node of the upper board wall module 2, the upper end of the lower board wall module 1 is provided with a cup mouth on both sides, and the cup mouth is formed by The cup mouth sleeve 101, the cup mouth steel plate 102, the peg connecting plate 104 and the first peg 105 are composed. The cup mouth steel plate 102 is located on both sides of the cup mouth, and the side of the cup mouth steel plate 102 close to the cup mouth is connected with a peg. plate 104, the stud connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com