Bridge hoisting machine

A hoisting machine and bridge technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of uneven distribution of suspending ropes, affecting the stability of rope collection, and large crane volume, etc. Realize automatic control of uniform rope retraction and improve the effect of construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

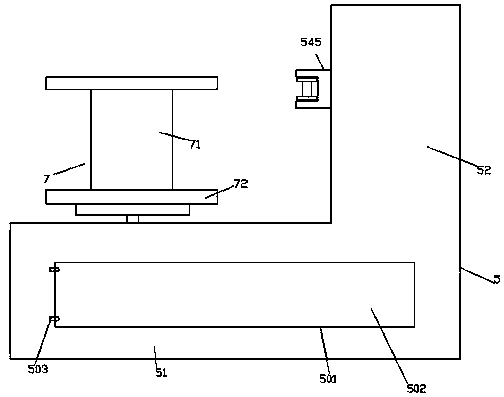

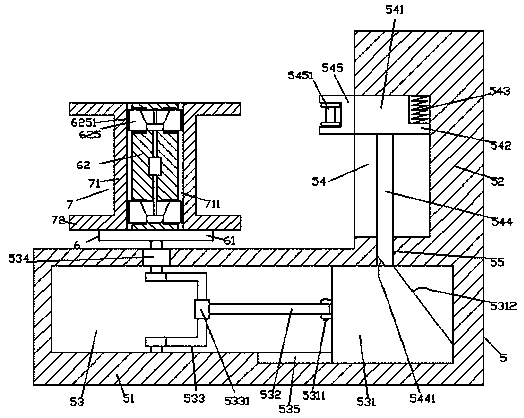

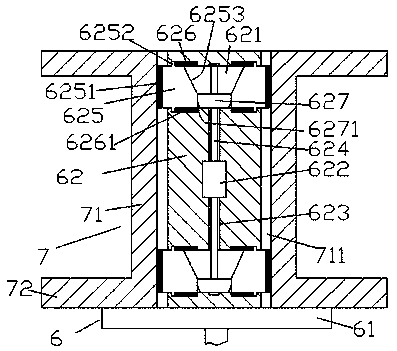

[0022] Such as Figure 1-Figure 6 As shown, a bridge hoisting machine of the present invention includes a rope receiving base 5 composed of a first base 51 and a second base 52. The first base 51 is provided with an inner chamber 53 extending from left to right. The right side of the chamber 53 is provided with a first sliding joint groove 535, and the first sliding joint groove 535 is provided with a sliding joint block 531 for sliding joint connection, and the left side of the sliding joint block 531 in the inner cavity 53 is A pin sleeve 5311 is provided on it, and a push rod 532 extending to the left is connected inside the pin sleeve 5311. A pin sleeve 5331 is provided at the left end of the push rod 532. The pin sleeve 5331 There is a curved pin shaft 533 inside, the front side of the curved pin shaft 533 is transferred to the inner wall of the front side of the inner cavity 53, and the rear side of the curved pin shaft 533 is connected with the rope-retracting motor 534...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com