Coarse-fine-particle mixed soil and preparation method thereof

A technology of mixing soil and thickness, which is applied in the field of civil engineering, can solve the problems of easy dispersion, poor cementation, and difficult molding of mixed soil, and achieve the effect of simple raw materials, high density, and difficult to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

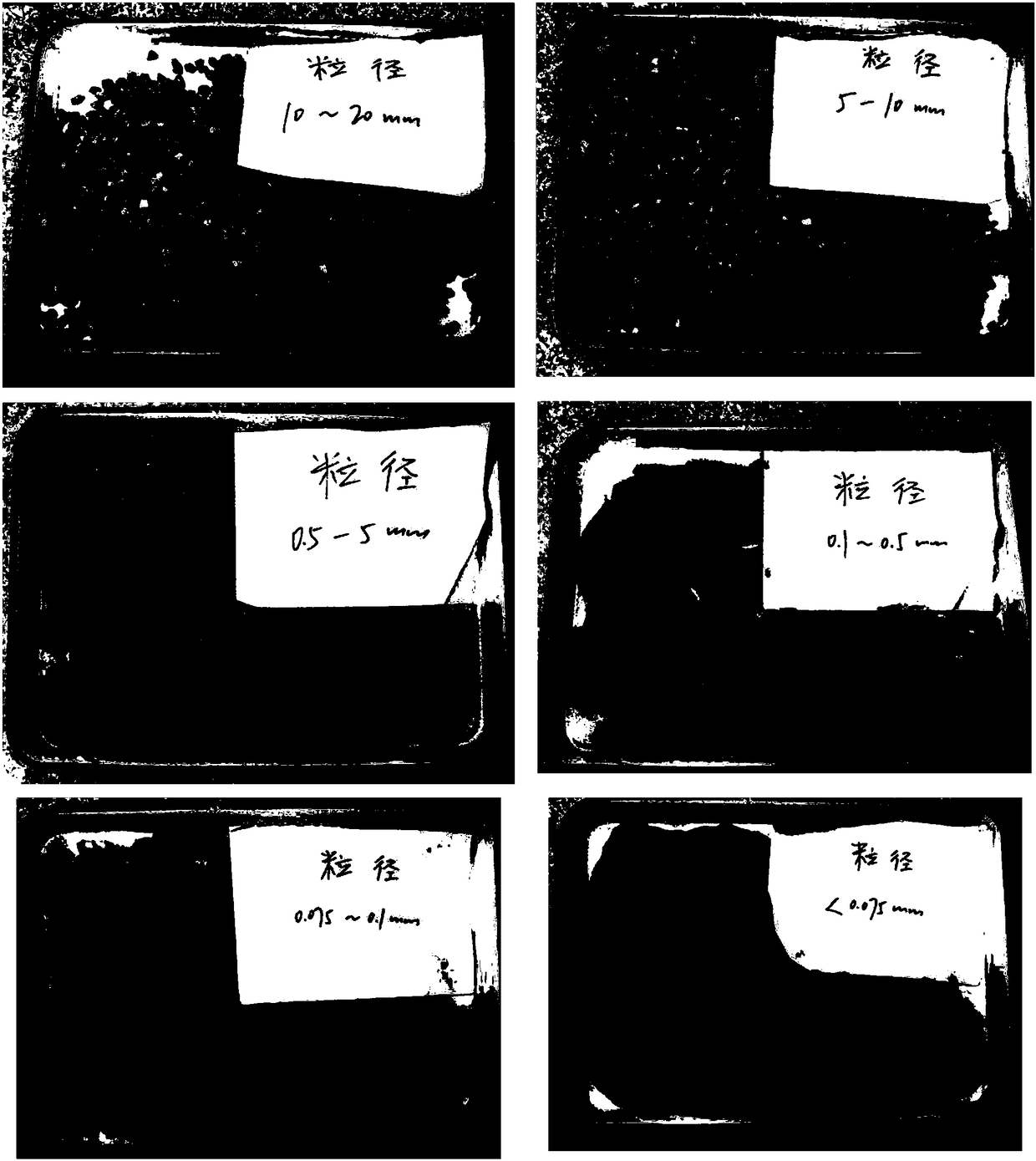

[0057] Raw material preparation:

[0058] Gravel with a particle size of 10-20mm: 3872g;

[0059] Gravel with a particle size of 5-10mm: 2790g;

[0060] Gravel with a particle size of 0.5-5mm: 1004g;

[0061] Gravel with a particle size of 0.1-0.5mm: 1000g;

[0062]Powder clay with a particle size of 0.075-0.1mm: 374g;

[0063] Powder clay with particle size less than 0.075mm: 960g.

[0065] The specific operation steps are as follows:

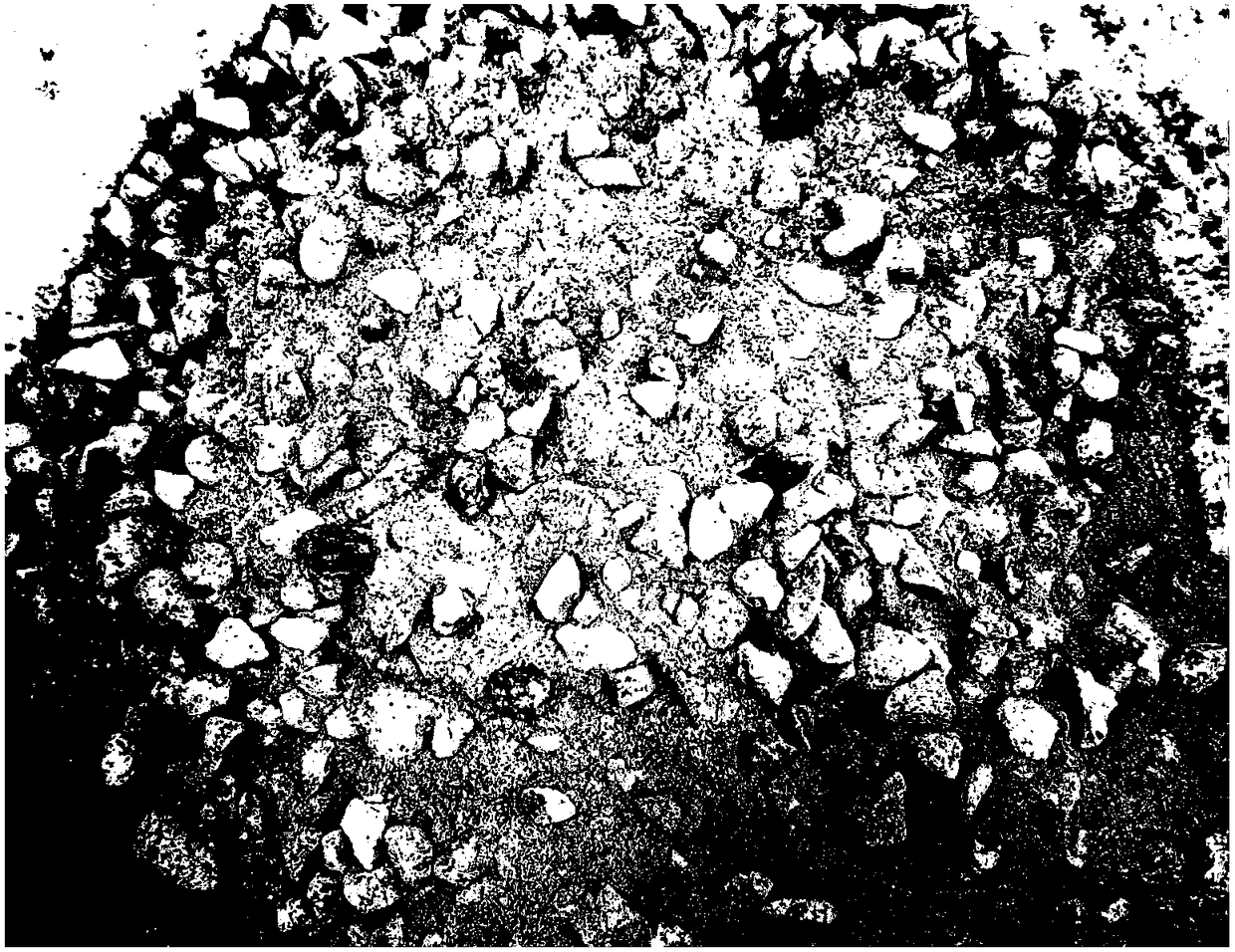

[0066] (1) Calculate the quality of the soil material required for the sample according to the relative density of 0.8, and weigh the raw material according to the raw material preparation to obtain the following: figure 1 Soil materials of different particle sizes and such as figure 2 For the cementitious material calcium oxide shown, mix gravel, powder clay and calcium oxide evenly to obtain image 3 Material 1 shown;

[0067] (2) Add 1.26kg of water to material 1 and stir, add water for the first tim...

Embodiment 2

[0072] Raw material preparation:

[0073] Gravel with a particle size of 10-20mm: 3400g;

[0074] Gravel with a particle size of 5-10mm: 2600g;

[0075] Gravel with a particle size of 0.5-5mm: 900g;

[0076] Gravel with a particle size of 0.1-0.5mm: 900g;

[0077] Powder clay with a particle size of 0.075-0.1mm: 400g;

[0078] Powder clay with particle size less than 0.075mm: 800g.

[0080] The specific operation steps are as follows:

[0081] (1) Prepare and weigh raw materials according to raw material preparation, mix gravel, powder clay and calcium oxide evenly, obtain material 1;

[0082] (2) Add 1128g of water to material 1 and stir, add water according to the moisture content of material 1 at 12% for the first time, add water to material 1 and stir evenly, after the material is cooled, add water for the second time to ensure the moisture content of material 10%, get material 2;

[0083] (3) Load the material into the sample preparat...

Embodiment 3

[0087] Raw material preparation:

[0088] Gravel with a particle size of 10-20mm: 3800g;

[0089] Gravel with a particle size of 5-10mm: 2500g;

[0090] Gravel with a particle size of 0.5-5mm: 1100g;

[0091] Gravel with a particle size of 0.1-0.5mm: 1100g;

[0092] Powder clay with a particle size of 0.075-0.1mm: 500g;

[0093] Powder clay with particle size less than 0.075mm: 1000g.

[0095] The specific operation steps are as follows:

[0096] (1) Prepare and weigh raw materials according to raw material preparation, mix gravel, powder clay and calcium oxide evenly, obtain material 1;

[0097] (2) Add 1272g of water to material 1 and stir. Add water according to the moisture content of material 1 at 12% for the first time, add water to material 1 and stir evenly. 14%, get material 2;

[0098] (3) Load the material into the sample preparation cylinder in 2 minutes and 5 times. The diameter of the sample preparation cylinder is 100mm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com