bga rework station with adjustable air outlet

A technology for rework stations and air outlets, which is applied in the secondary processing of printed circuits, etc. It can solve the problems that the size of the air outlet cannot be adjusted, BGA chips spread around, and influence, etc., and achieve the effect of improving the efficiency of desoldering and shortening the time of desoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further detailed explanation through specific implementation mode below:

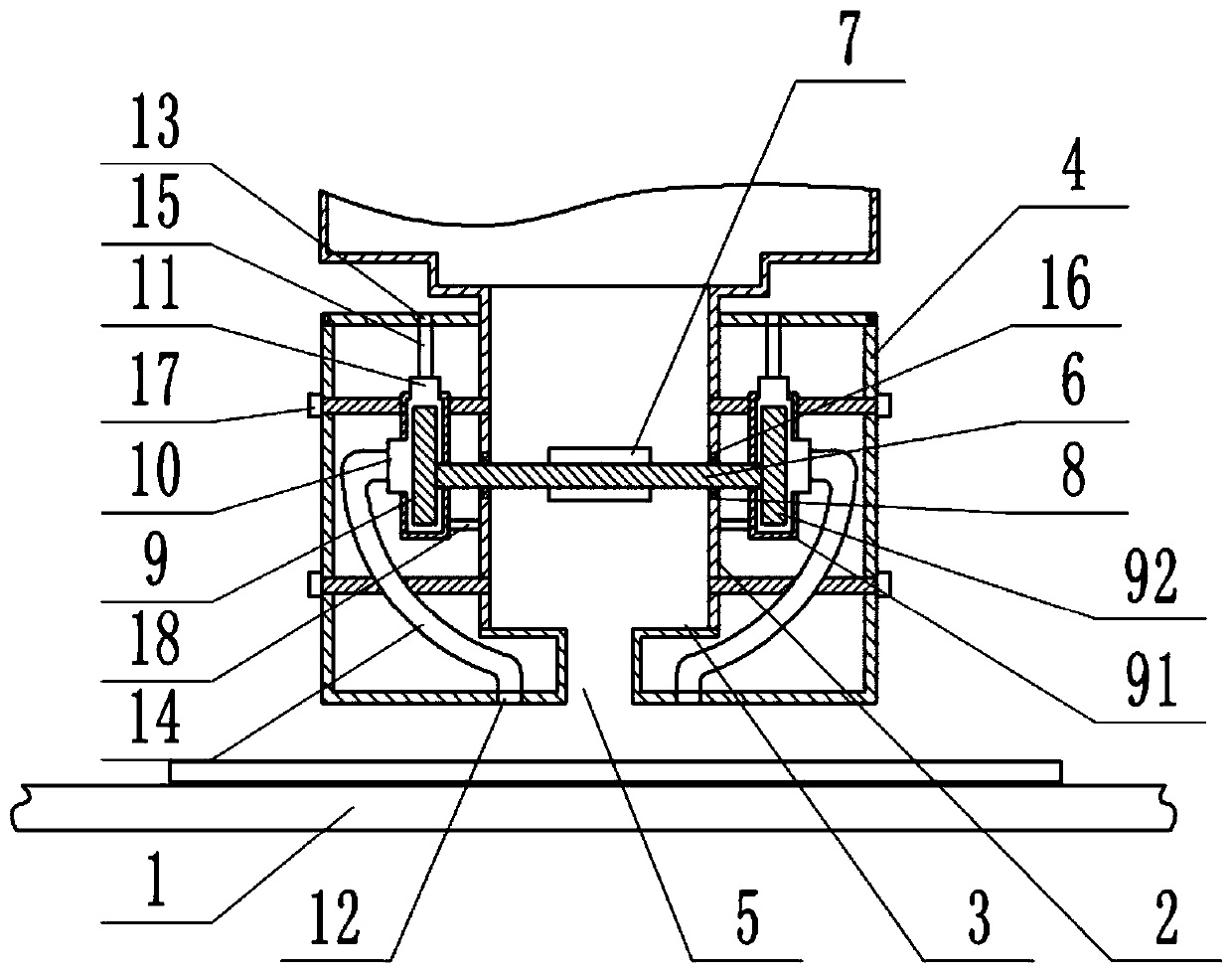

[0029] The reference signs in the drawings of the description include: machine 1, hot air nozzle 2, air outlet 3, regulating shell 4, opening 5, rotating shaft 6, first impeller 7, socket 8, centrifugal fan 9, casing 91, second Impeller 92, suction port 10, output port 11, through hole 12, air outlet hole 13, delivery pipe 14, exhaust pipe 15, rolling bearing 16, bolt 17, connecting block 18.

[0030] like figure 1 As shown, the BGA rework station with adjustable air outlet 3 of the present invention includes a machine 1 and a hot air assembly. The hot air assembly includes a heater and a hot air nozzle 2. The air outlet 3 is formed at the hot air nozzle 2, and the hot air nozzle 2 is covered with a regulating shell. 4. The adjusting shell 4 is detachable relative to the hot air nozzle 2. In this embodiment, the adjusting shell 4 and the hot air nozzle 2 are connected by bolts 17, such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com