A kind of display panel, electronic equipment and preparation method of display panel

A display panel, one-sided technology, applied in circuits, electrical components, electrical solid-state devices, etc., can solve the problems of light leakage of the display panel, uneven brightness of the display image, affecting the display effect, etc., to achieve uniform screen brightness, better display effect, show uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically described below in conjunction with the accompanying drawings.

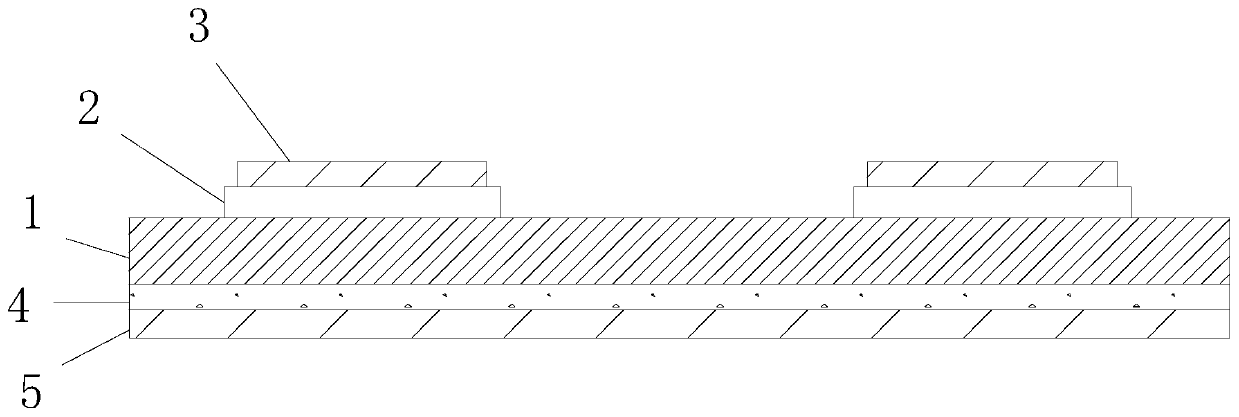

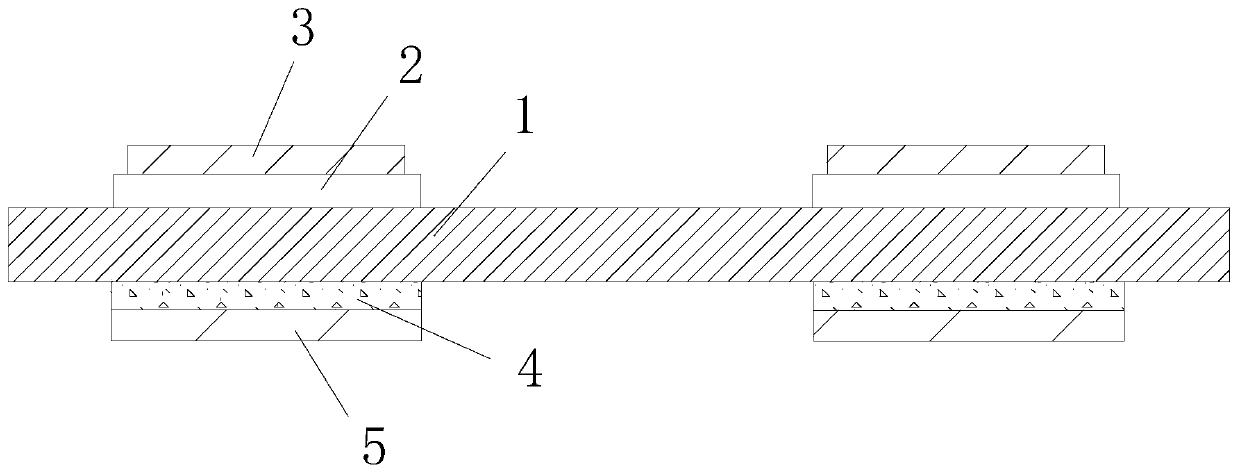

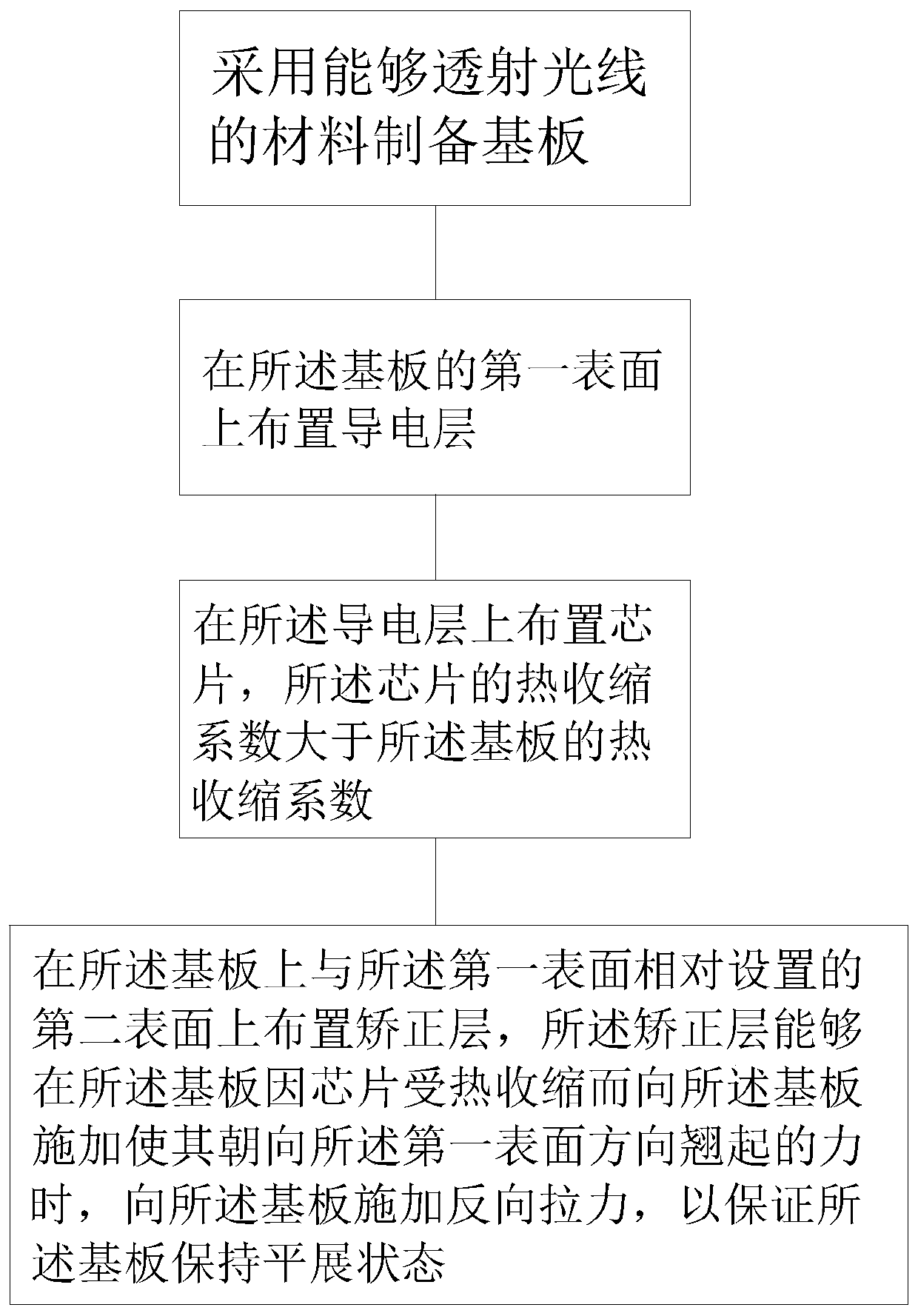

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a display panel, including a substrate 1 capable of transmitting light, a thermally deformed portion is provided on the first surface of the substrate 1, and a correction layer is provided on the second surface of the substrate opposite to the first surface. 5. The rectifying layer 5 is used to balance the thermally deformable part and / or the force for deforming the substrate 1 generated by heating the substrate 1, so as to maintain the form of the substrate 1, that is, to maintain the substrate 1 in a flat state.

[0030] Specifically, a conductive layer 2 is provided on the first surface of the substrate 1, and the thermally deformed part is a chip 3 arranged on the conductive layer 2, wherein the chip 3 is made of a material whose thermal contraction coefficient is greater than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com