Device and method for measuring location of center of mass based on forward tilting platform and wheel load meter

A technology of measuring device and wheel load meter, which is applied in the direction of measuring device, static/dynamic balance test, machine/structural component test, etc., can solve the problem of large rear bearing load, etc., and achieve the effect of scientific results and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

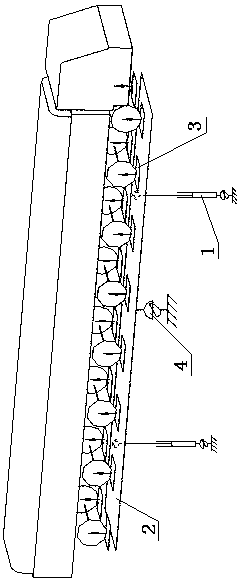

[0035] A center-of-mass position measuring device based on a forward tilting platform and a wheel loader, which consists of: a drive cylinder, a bearing platform and a wheel loader, the bottom of the drive cylinder is connected to the foundation through bolts, and the top of the drive cylinder Supporting the bearing platform, the lower part of the bearing platform is connected with the connecting hinge, and a group of the wheel load meters are evenly placed on the bearing platform, and the upper part of each of the wheel load meters corresponds to For the corresponding wheels, the wheel load meter can normally measure wheel load data in a horizontal state.

Embodiment 2

[0037] A method for measuring the center of mass position measuring device based on the forward tilt platform and the wheel load meter described in embodiment 1, the method comprises the following steps:

[0038] (1) Wheelbase measurement: measure the wheelbase of the vehicle separately

[0039] (2) Wheelbase measurement: measure the wheelbase of the vehicle separately

[0040] (3) Wheel height measurement: measure the wheel height of the vehicle

[0041] (4) Arrange the position of the wheel loader according to the wheelbase and wheelbase;

[0042] (5) The vehicle under test drives to the effective weighing area and stops;

[0043] (6) Ensure that the surface of each wheel loader is level; read the measured value of each wheel loader , calculate the axle load , vehicle weight and unilateral weight:

[0044]

[0045] Calculate the front and rear center of mass positions of the vehicle :

[0046] Calculate the position of the vehicle's left and right center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com