Method for predicting volume content of corrosion pores in carbonate reservoir

A carbonate reservoir, pore volume technology, applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of pore type volume content prediction, which cannot be used for carbonate reservoirs , unable to characterize the influence of elastic modulus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

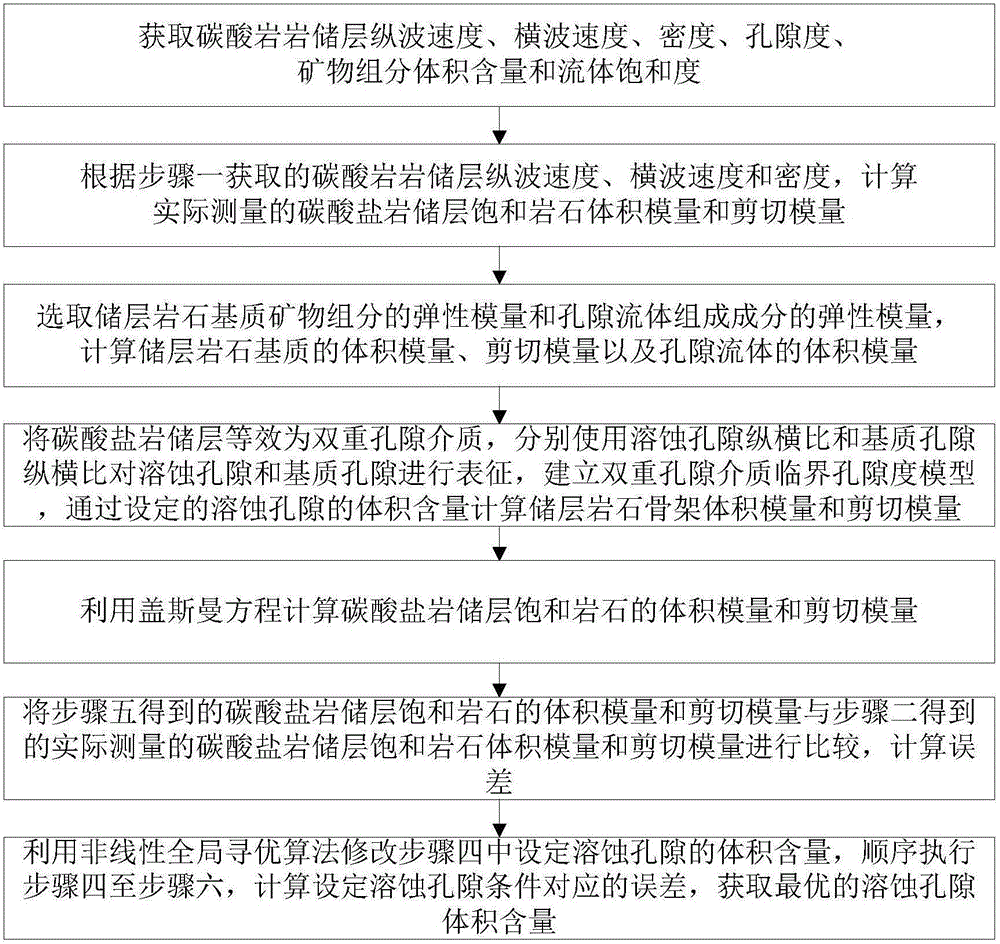

[0044] Such as figure 1 As shown, a method for predicting the volume content of dissolved pores in carbonate rock reservoirs includes the following steps:

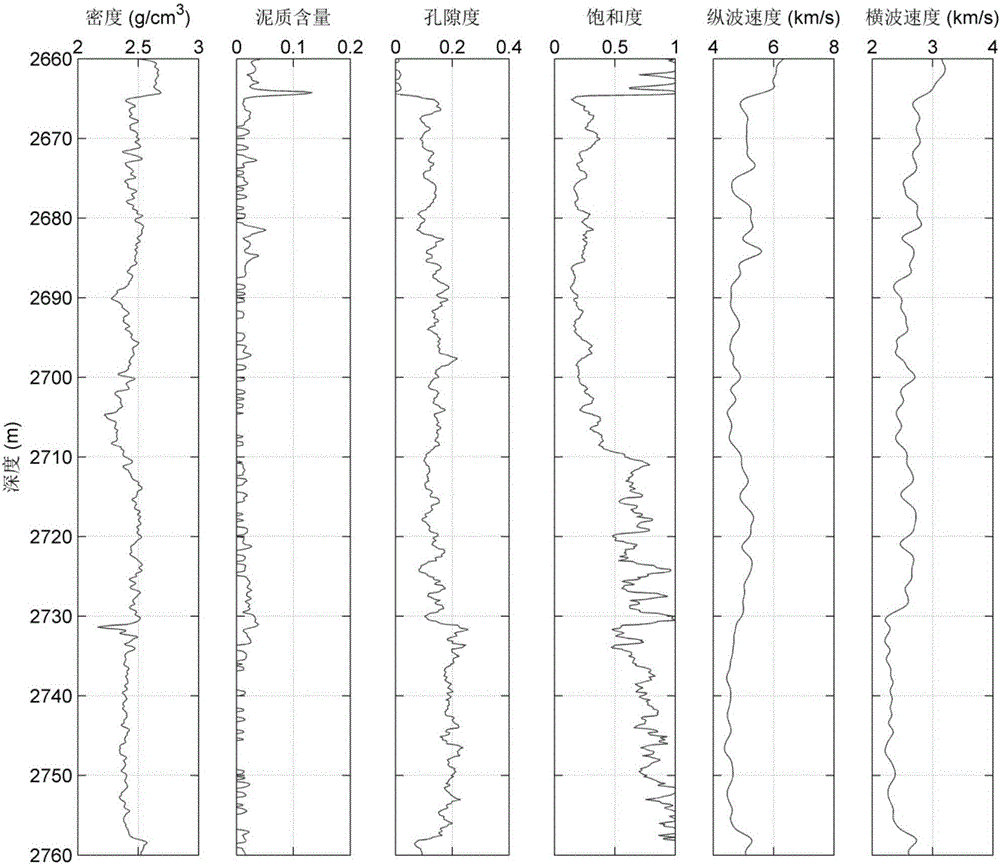

[0045] Step 1: Obtain the P-wave velocity, S-wave velocity, density, porosity, volume content of mineral components and fluid saturation of carbonatite reservoir; figure 2 It is the logging curve of a gas-bearing well in an overseas oilfield, including carbonatite reservoir compressional wave velocity, shear wave velocity, density, porosity, mineral component volume content and fluid saturation.

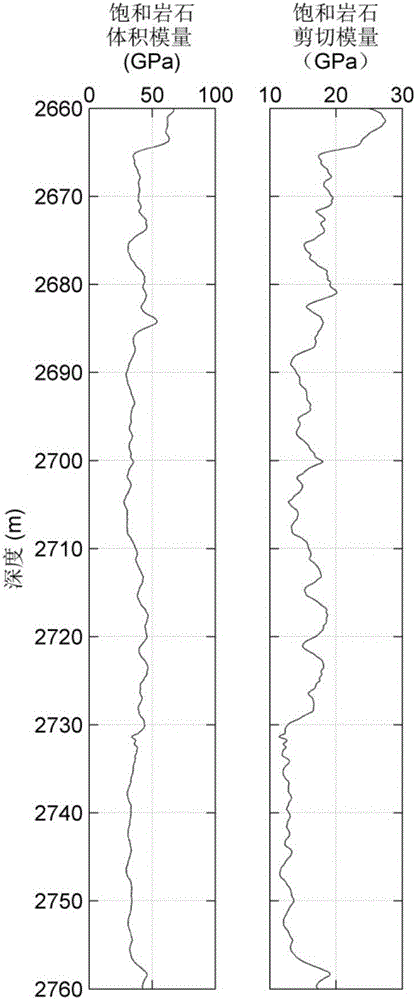

[0046] Step 2: Calculate the actual measured saturated rock bulk modulus and shear modulus of the carbonate reservoir according to the P-wave velocity, S-wave velocity and density obtained in Step 1;

[0047] Such as figure 2 As shown, the above parameters are obtained by calculating the compressional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com