Double-spectral line feature-based standard temperature method

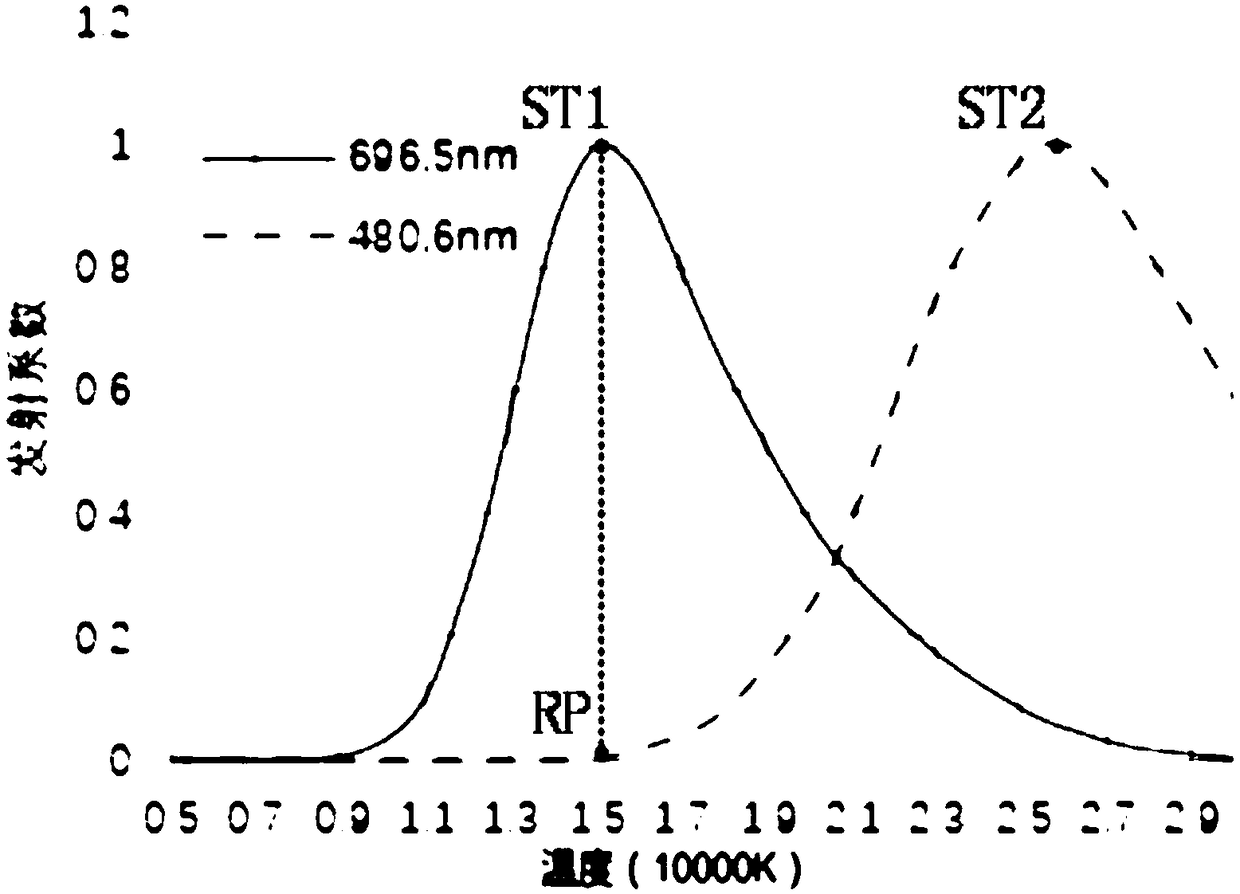

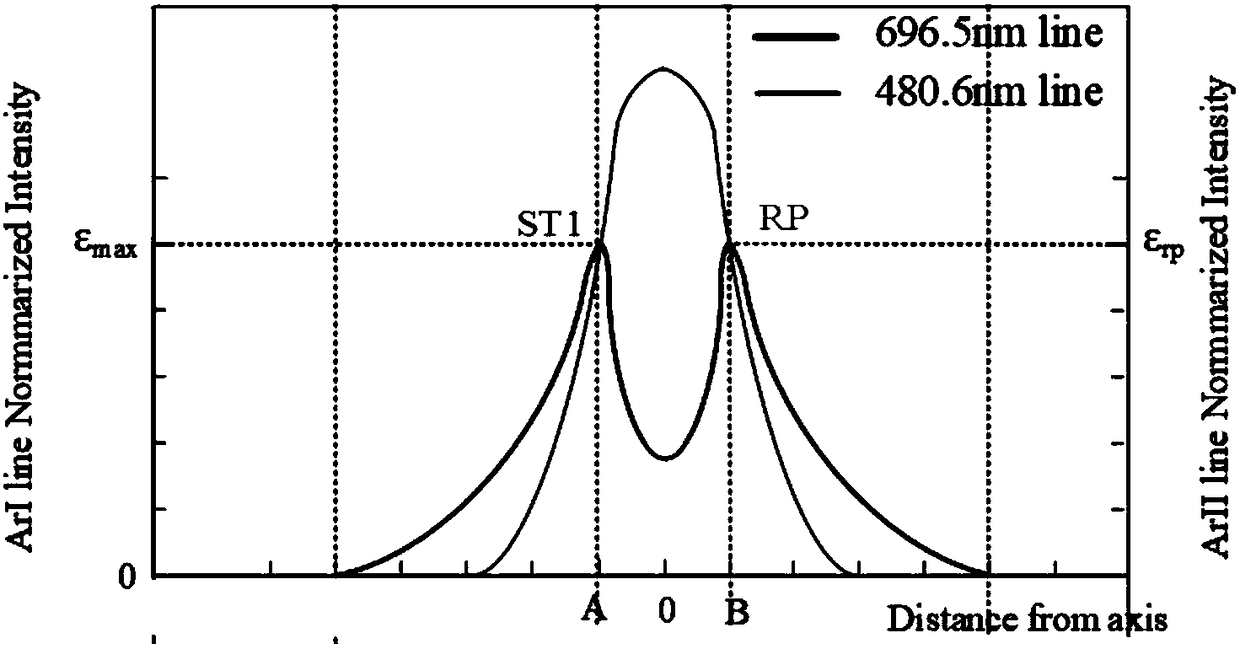

A temperature method and bispectral technology, which is applied in the field of plasma temperature measurement, can solve the problems of no automatic method to determine the temperature of the arc center area, and cannot automatically determine the temperature value at the minimum emission coefficient, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objects, technical solutions and advantages of the present invention more clearly understood, below in conjunction with accompanying drawing and embodiment, to

[0026] The present invention is further described in detail.

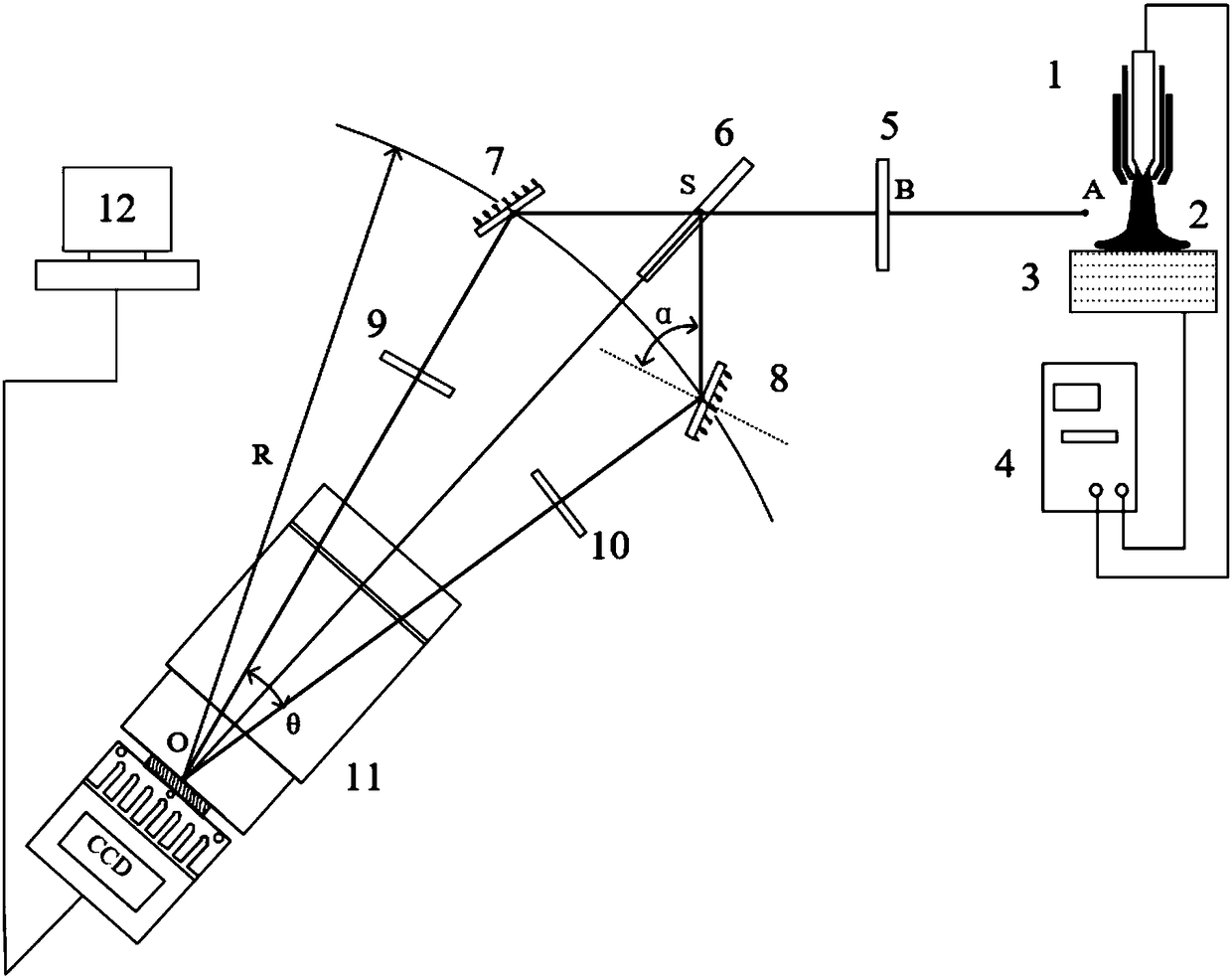

[0027] 1. If figure 1 As shown, refer to the position of the welding arc 2 to build the measurement optical path. The area between the welding torch 1 and the workpiece 3 is the arc space, and the center A of the arc 2, the center B of the polarizer 5, and the center S of the beam splitter 6 are arranged in a straight line, and the center line of the three is perpendicular to the center of the arc. Wherein, the angle between the beam splitter 6 and the central line AS is 45 degrees. Angle∠M 1 SM 2 at 90 degrees, SM 1 =SM 2 , and 7 mirrors M 1 and 8 mirrors M 2 It is symmetrical about the extension line of the beam splitter 6 . Mirror M 1 and M 2 Arranged on the arc track centered on the position O of the photosensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com