Vehicle-mounted weighing system of freight train as well as weighing method

A freight train and weighing technology, which is applied in the field of real-time monitoring of the on-board weighing of freight trains, can solve problems such as endangering driving safety, inconvenience, and damage to vehicle equipment, and achieves prevention of overloading and partial loading, simple structure, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below by examples.

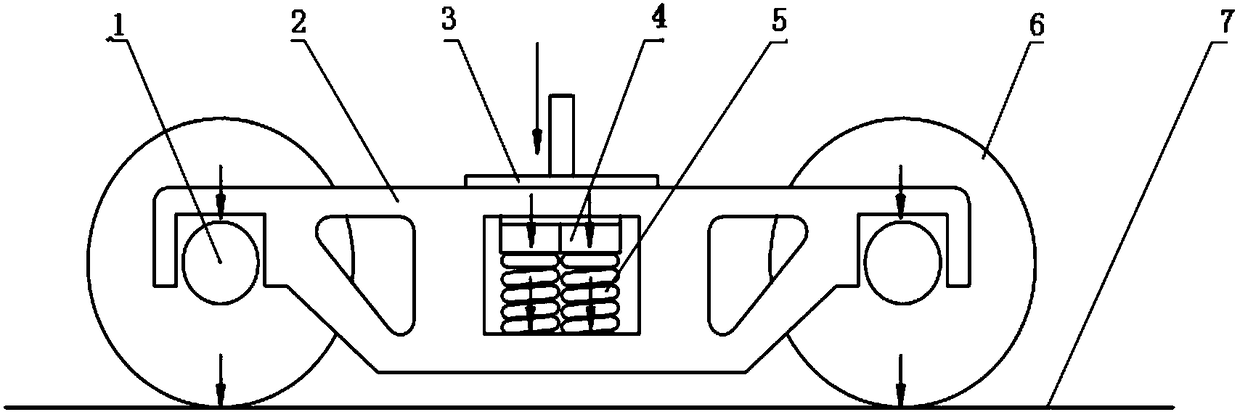

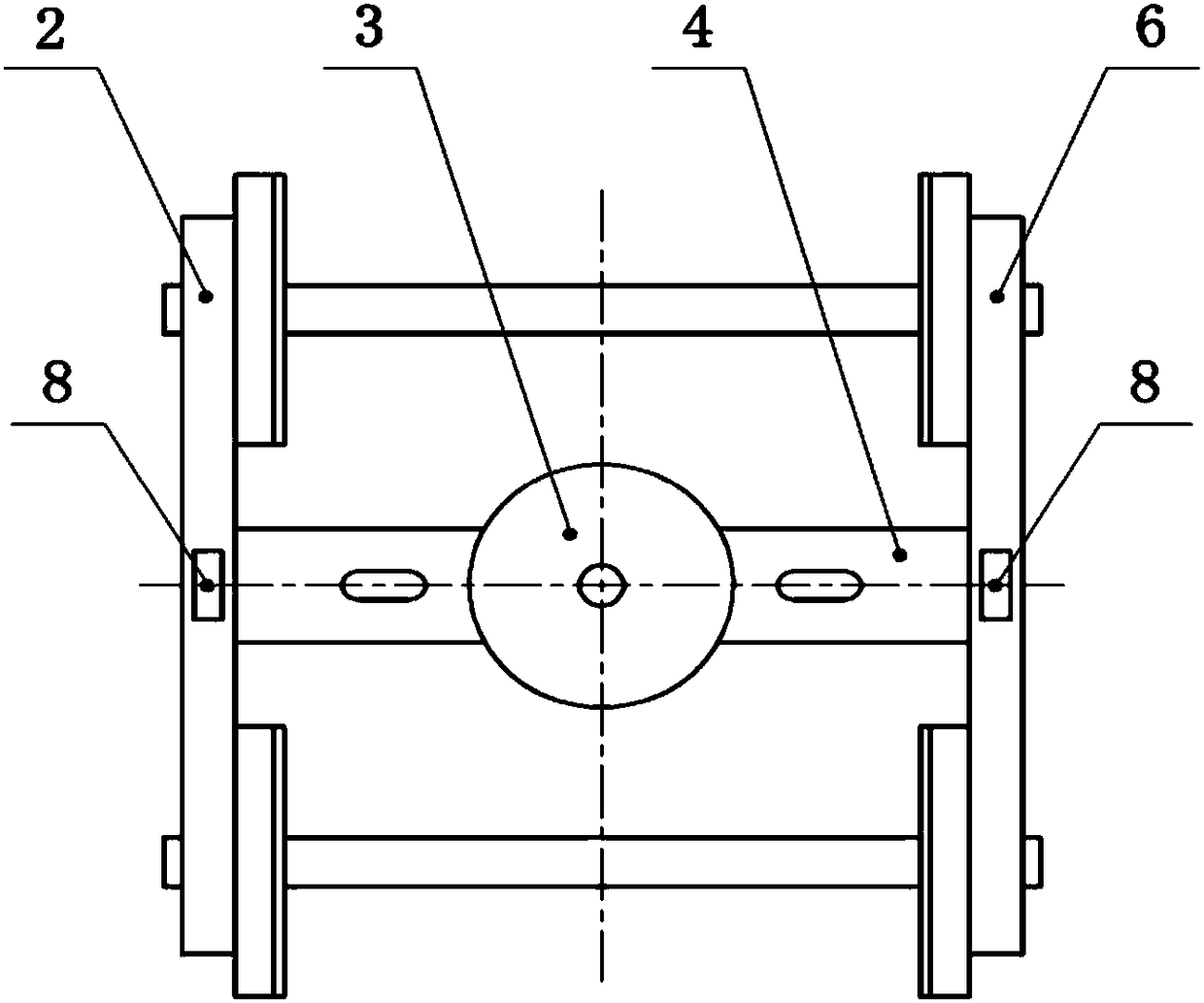

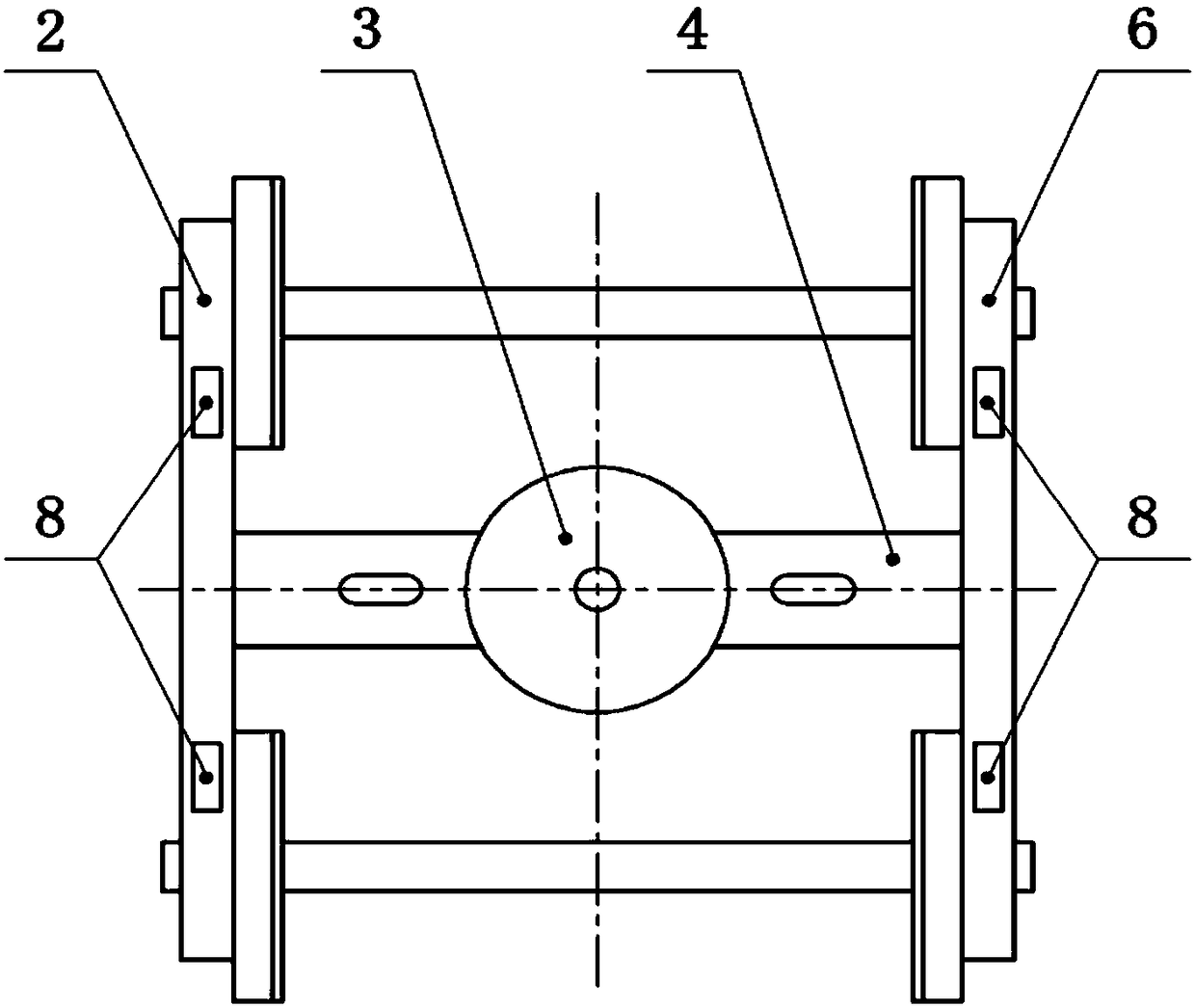

[0027] In order to realize the self-weighing of the freight train, combined with the structure of the freight train itself, an indirect weighing mode based on the strain of the two sets of sideframes of the bogie is selected. After the freight car is loaded with a certain tonnage, it will cause the corresponding deformation and stress distribution of the bogie. A special load cell 8 is installed at an appropriate position of the side frame 2 to indirectly realize the measurement of the load capacity. The position error caused by the change of the center of gravity can be eliminated by a reasonable layout of the sensors 8, so as to achieve the purpose of improving the weighing accuracy.

[0028] From figure 1 It can be seen that the weight transfer order of the freight train after the cargo is added is that the cargo is loaded on the freight car, and the car sits on the lower center plate 3 of the bogie,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com