Pressure welding device and method for high-temperature superconducting strips

A technology of high-temperature superconducting tape and crimping device, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. Contamination and other problems, to achieve the effect of excellent transverse shear stress performance, low cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better explain the present invention and facilitate understanding, the following describes the present invention in detail through specific embodiments in conjunction with the accompanying drawings.

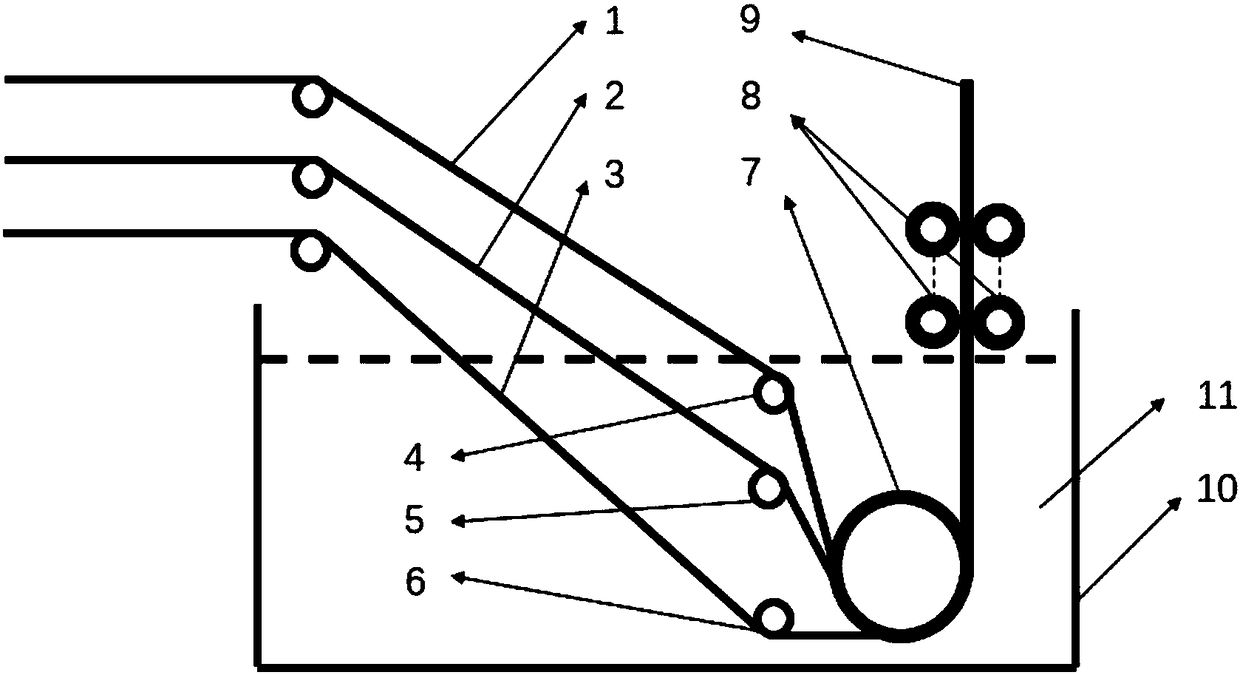

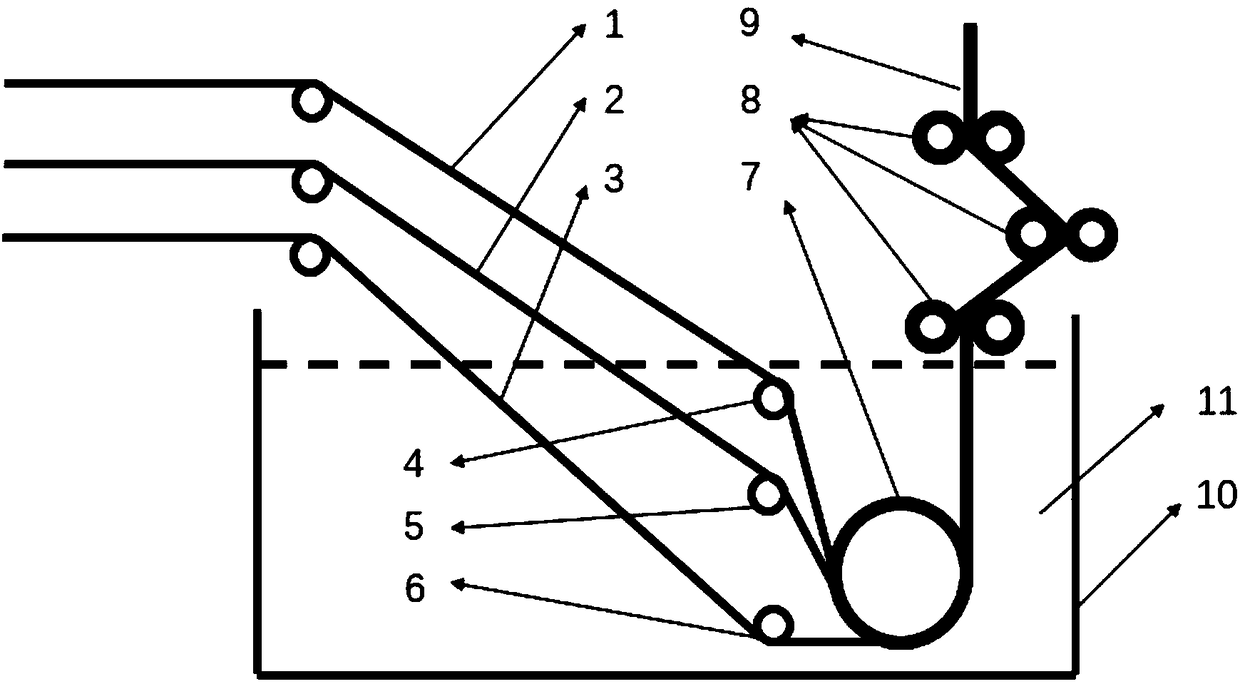

[0044] Such as figure 1 Shown: This embodiment discloses a crimping device and method for high-temperature superconducting tape.

[0045] Specifically, it includes a solder pool 10, positioning devices 4, 5, 6 arranged in the solder pool, a rotating device 7 and a crimping device 8 arranged above the solder pool 10; the solder pool 10 is used for holding molten solder 11.

[0046] The temperature of the molten solder described here is between 183°C and 250°C.

[0047] The positions of the positioning devices 4, 5, and 6 are adjustable and are used to precisely control the positions of the metal strips 1, 3 and the superconducting center layer 2, respectively, so that the superconducting strip center layer 2 is located in the middle of the metal strips 1, 3, and ensures ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com